Lithium ion capacitor and preparation method therefor

A lithium ion and capacitor technology, applied in the field of lithium ion capacitors, can solve problems such as limiting the application of lithium ion capacitors, increasing equipment and process costs, etc., and achieves the effects of saving preparation costs, simplifying processes and equipment, and reducing heat treatment energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In a lithium ion capacitor of the present invention, the positive electrode material is a porous carbon material, and the negative electrode material is a graphitized carbon material.

[0041] The preparation method includes the following steps:

[0042] (1) Preparation of porous carbon materials:

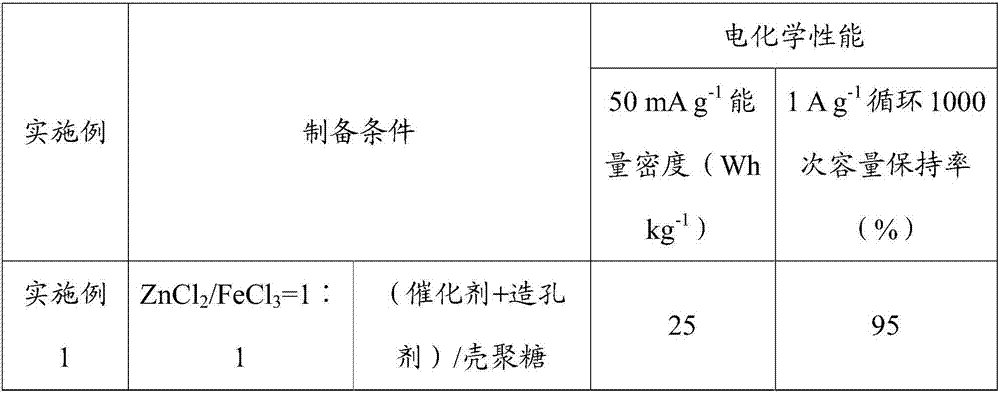

[0043] 1.1, the pore former (ZnCl 2 ) And catalyst (FeCl 3 ) Mix according to the mass ratio of 1:1 to obtain ZnCl 2 / FeCl 3 Mixture, ZnCl 2 / FeCl 3 The mixture is mixed with the carbon source (chitosan) at a mass ratio of 0.01:1 to obtain the first mixture.

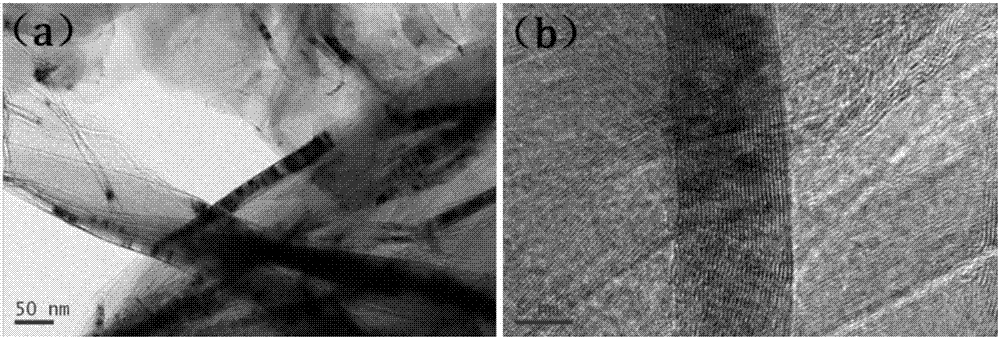

[0044] 1.2. After the first mixture of step 1.1 is ground in a mortar for 5 minutes, it is placed in a tube furnace under the protection of inert gas for heat treatment, specifically: heating at 2°C / min to 110°C, and at 110°C Heat preservation for 2h; then heat up to 600°C at 2°C / min, and carbonize at 600°C for 2h; then heat up to 700°C at 2°C / min, and pore-forming treatment at 700°C for 0.5h to obtain the first heat treatment...

Embodiment 2

[0054] In a lithium ion capacitor of the present invention, the positive electrode material is a porous carbon material, and the negative electrode material is a graphitized carbon material.

[0055] The preparation method includes the following steps:

[0056] (1) Preparation of porous carbon materials:

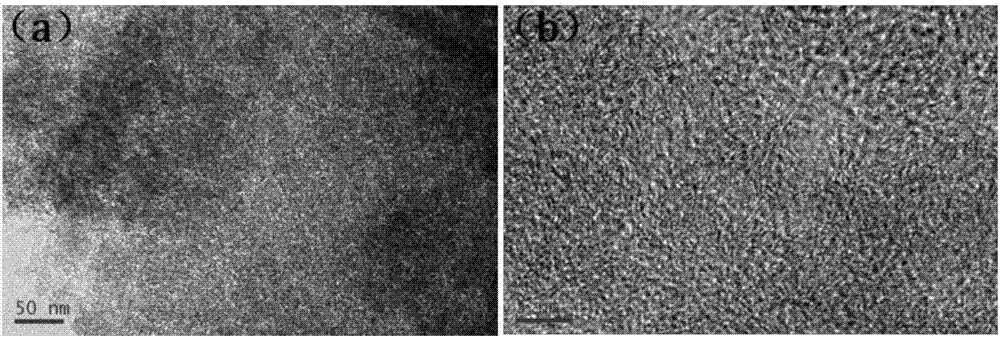

[0057] 1.1, the pore former (SnCl 2 ) And catalyst (NiCl 2 ) Mix according to the mass ratio of 1:1 to obtain SnCl 2 / NiCl 2 Mixture, the SnCl 2 / NiCl 2 The mixture is mixed with the carbon source (carboxymethyl chitosan) at a mass ratio of 1:1 to obtain the first mixture.

[0058] 1.2. After the first mixture of step 1.1 is ground in a mortar for 5 minutes, it is placed in a tube furnace under the protection of inert gas for heat treatment, specifically: heating at 2°C / min to 110°C, and at 110°C Heat preservation for 2h; then heat up to 600°C at 2°C / min, and carbonize at 600°C for 2h; then heat up to 700°C at 2°C / min, and pore-forming treatment at 700°C for 0.5h to obtain the first...

Embodiment 3

[0066] In a lithium ion capacitor of the present invention, the positive electrode material is a porous carbon material, and the negative electrode material is a graphitized carbon material.

[0067] The preparation method includes the following steps:

[0068] (1) Preparation of porous carbon materials:

[0069] 1.1. Mix the pore former (KOH) and the carbon source (glucose) at a mass ratio of 10:1 to obtain the first mixture.

[0070] 1.2. After the first mixture of step 1.1 is ground in a mortar for 5 minutes, it is placed in a tube furnace under the protection of inert gas for heat treatment, specifically: heating at 2°C / min to 110°C, and at 110°C Heat preservation for 2h; then heat up to 600°C at 2°C / min, and carbonize at 600°C for 2h; then heat up to 700°C at 2°C / min, and pore-forming treatment at 700°C for 0.5h to obtain the first heat treatment product.

[0071] 1.3. Wash the heat-treated product of step (2) 3 times with 4mol / L dilute hydrochloric acid, and then wash with deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com