Wiredrawing system for steel wires

A technology of steel wire and wire drawing machine, applied in the field of wire drawing system, can solve the problems of affecting the quality of the steel wire, increasing the processing procedure, and breaking the wire rod, so as to improve the management efficiency and production efficiency, improve the quality of wire drawing, and reduce the friction force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

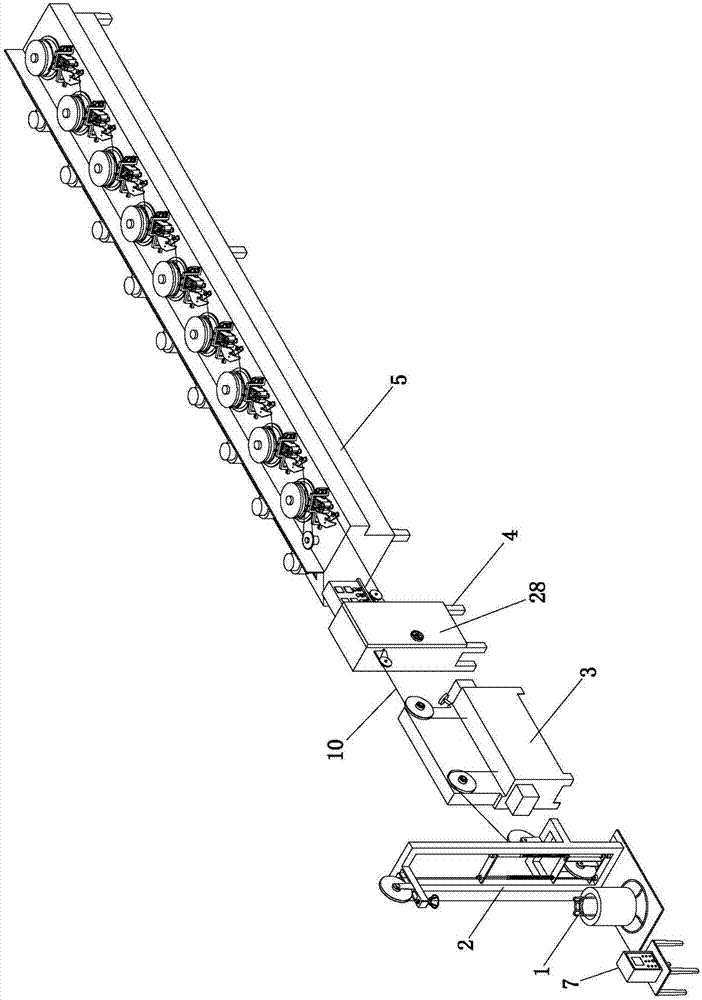

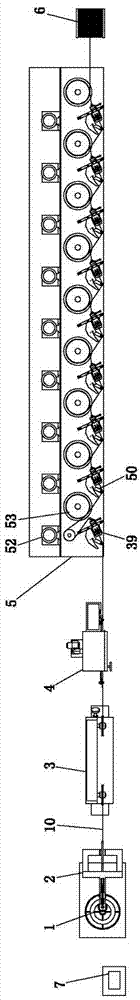

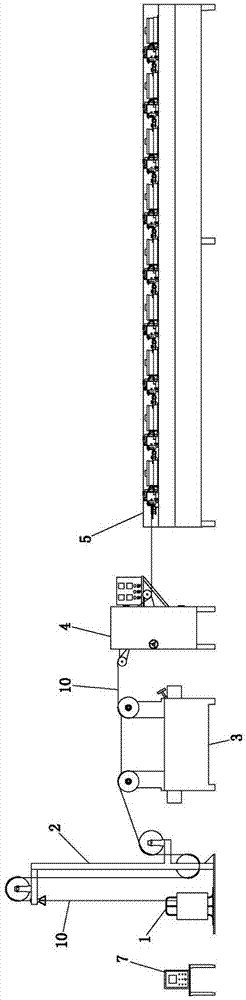

[0031] The present invention will be further described below in conjunction with accompanying drawing:

[0032] Referring to the accompanying drawings: the steel wire drawing system in this embodiment includes a pay-off frame 1, a wire management device 2, a single-wire film device 3, an online film oven 4, a wire drawing machine 5, a wire take-up frame 6, and a wire management device arranged in sequence. Device 2, single-line film device 3, online film oven 4, wire drawing machine 5, and wire take-up frame 6 are all connected and controlled through the electric control box 7; the wire management device 2 includes a wire management frame 8, and a cross bar 9 is fixed on the upper part of the wire management frame 8 , the end of the cross bar 9 is provided with a lead hole 11 for the wire rod 10 to pass through, a first guide wheel 12 is arranged above the lead hole 11, and a trumpet-shaped cover with a larger inner diameter and a smaller inner diameter is fixed below the lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com