Aluminum alloy scrap recycling device and processing technology

A processing technology and aluminum alloy technology, which is applied in the field of aluminum alloy, can solve problems affecting product quality, etc., and achieve the effects of strong practicability, improved product quality, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

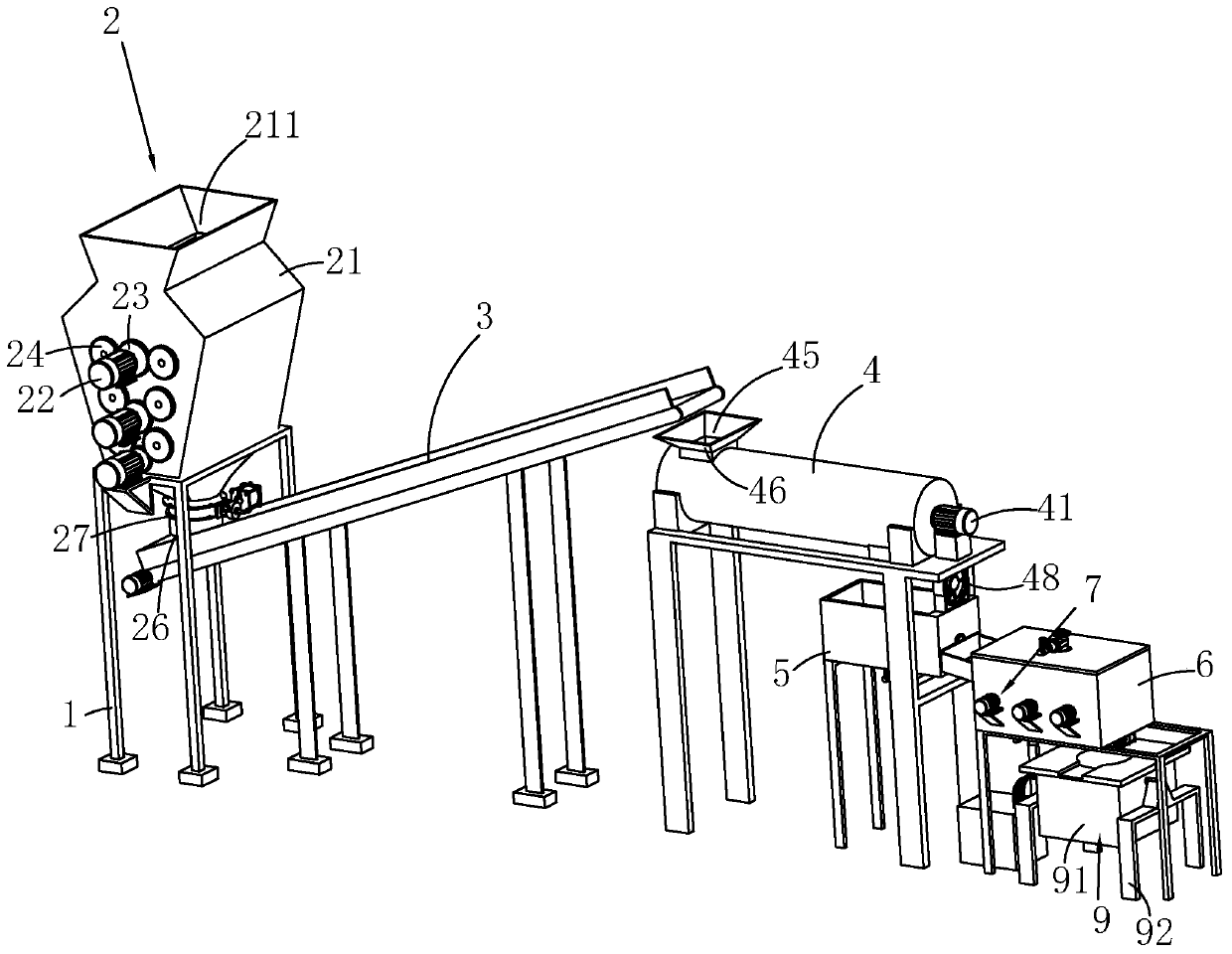

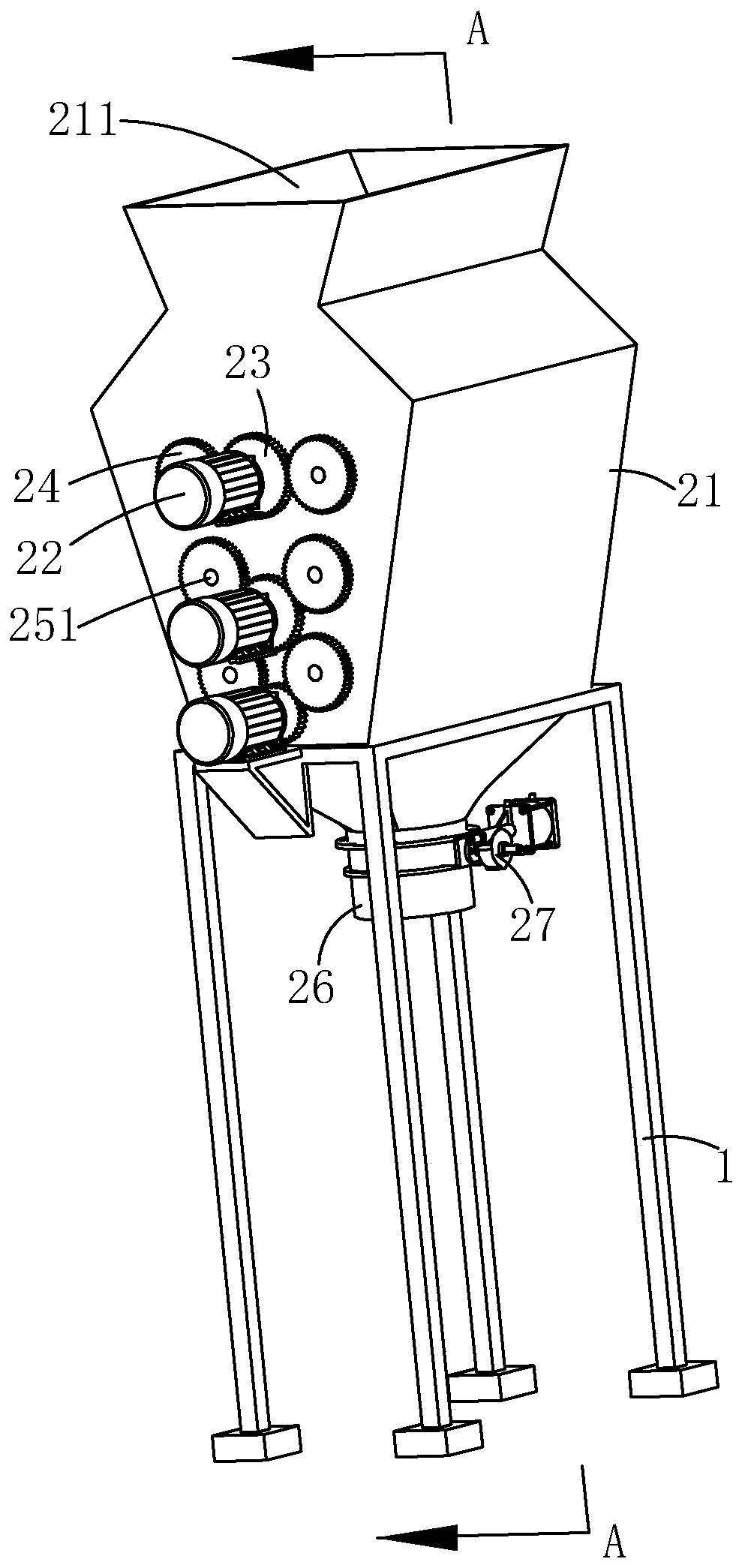

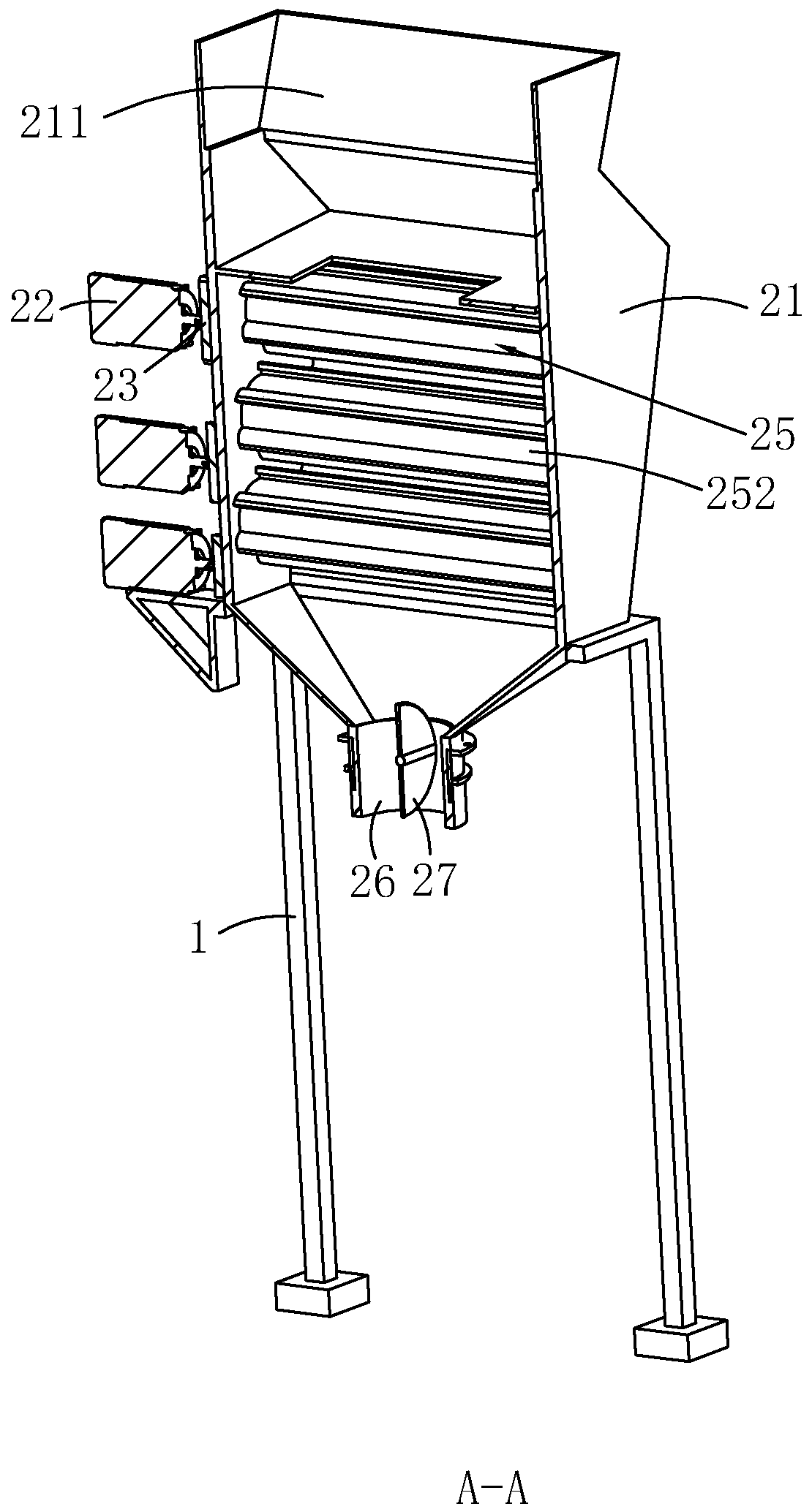

[0044] Such as figure 1 As shown, an aluminum alloy scrap recycling device includes a bracket 1 and a crushing device 2 located on the bracket 1, the discharge end of the crushing device 2 is provided with a conveyor belt 3 on the bracket 1, and the conveyor belt 3 is far away from the crushing device 2- Side is provided with the magnetic separation cylinder 4 that is positioned on the support 1, and the material receiving box 5 that is positioned at the support 1 is arranged below the discharge port of the magnetic separation cylinder 4, see Figure 5 , the opening of the top wall of the material receiving box 5 is provided, and the bottom wall of the material receiving box 5 is provided with a first liquid outlet 55, and the first liquid outlet 55 is provided with a first liquid outlet pipe 51 communicating with the first liquid outlet 55 , a first valve 52 is installed on the first liquid outlet pipe 51, a cleaning device 7 and a drying device 8 are arranged on the side of ...

Embodiment 2

[0051] A process for recycling aluminum alloy scraps, comprising the steps of:

[0052] Step 1: According to the reuse requirements of recycled aluminum raw materials, crush waste aluminum castings, waste aluminum forgings, waste aluminum profiles and waste aluminum chips in the recycled aluminum raw materials, so that the particle size meets the reuse requirements of recycled aluminum raw materials;

[0053] Step 2: magnetic separation, through the magnet 44, remove the mixed iron, steel and other metal compounds in the recycled aluminum raw materials;

[0054] Step 3: wind selection, adjust the air volume of the fan 48, so that it can remove waste paper, waste plastic film, dust and other sundries in the recycled aluminum raw materials;

[0055] Step 4: Acidification, preparing 3% sulfuric acid solution, injecting 3% sulfuric acid solution into the material receiving box 5, acidifying the regenerated aluminum raw material after winnowing, after acidifying for 1 min, the pain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com