Device used for automatically stacking mineral wool products

An automatic conveying device, cotton product technology, applied in the stacking of objects, destacking, transportation and packaging of objects, etc., can solve the problems of large floor space, low production efficiency, high operating costs, and achieve high repeatable positioning accuracy , to ensure the effect of strength and quality, high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

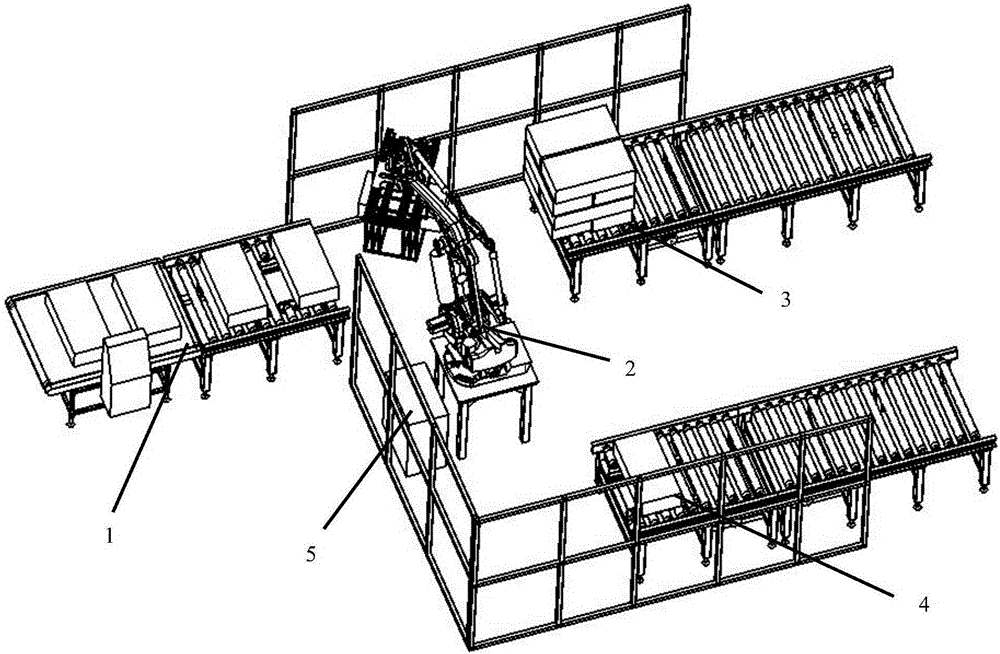

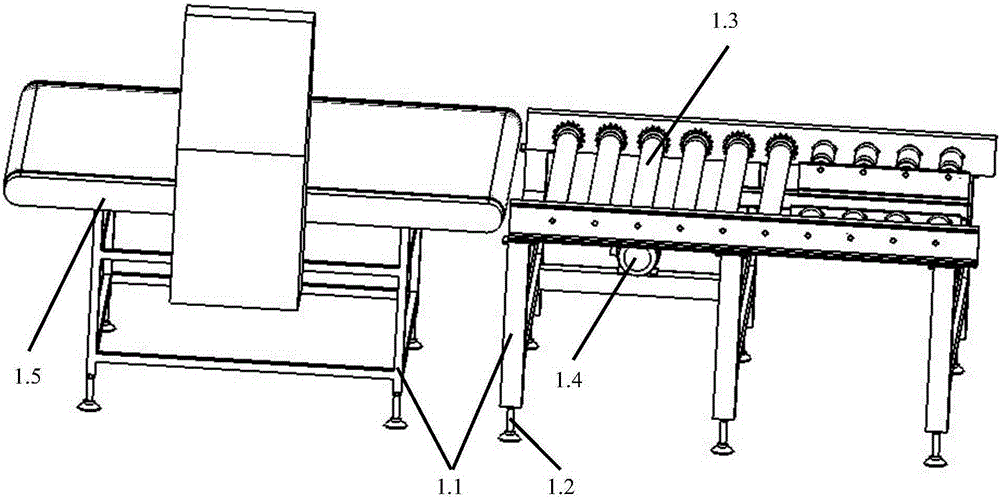

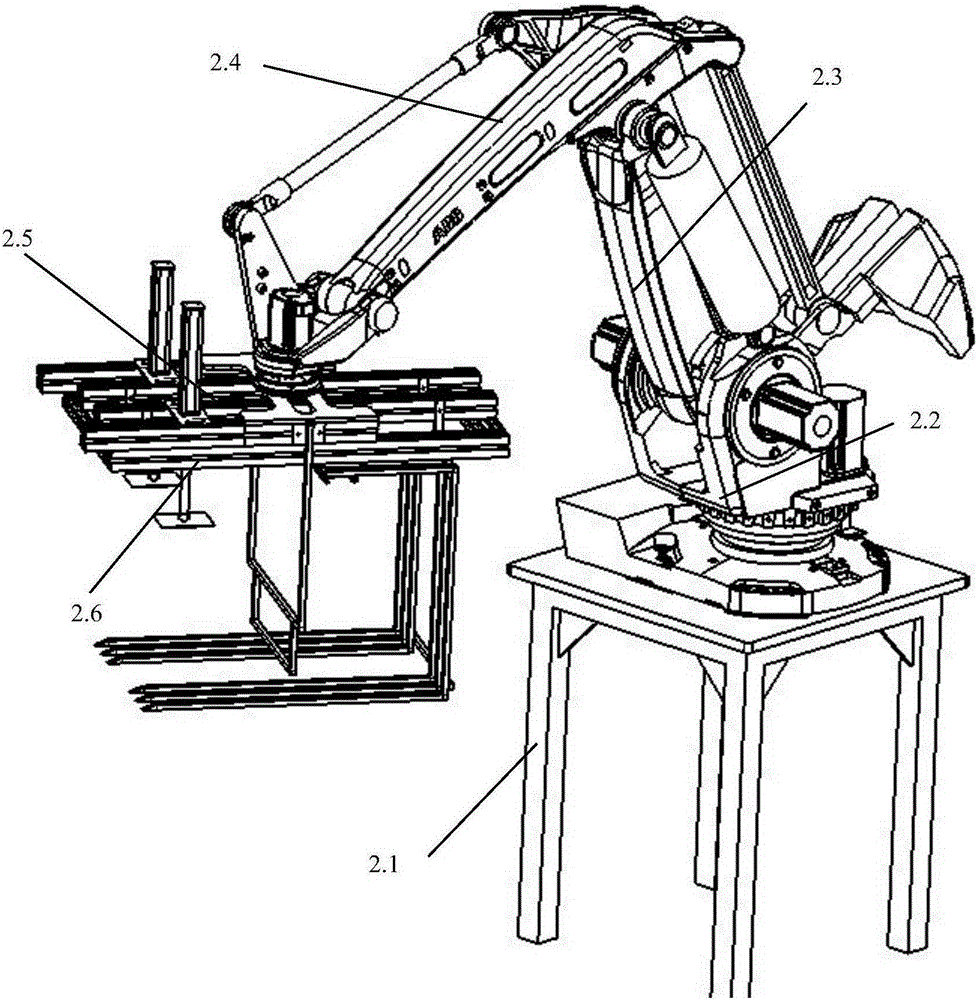

[0027] Such as figure 1 As shown, the device for automatic palletizing of mineral wool products includes automatic weighing conveyor line, four-axis automatic palletizing robot, first roller conveyor line, second roller conveyor line and central controller; automatic weighing conveyor Line, four-axis automatic palletizing robot, the first roller conveyor line and the second roller conveyor line are respectively connected to the central controller by communication; the automatic weighing conveyor line is arranged in the previous process of the four-axis automatic palletizing robot, and the first The first roller conveying line and the second roller conveying line are arranged in the last process of the four-axis automatic palletizing robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com