Complete hydraulic self-drilling type side pressure equipment

A self-drilling, full-hydraulic technology, applied in drilling equipment, drilling equipment and methods, earthwork drilling and mining, etc., can solve problems such as complicated operation, hindering the development of geotechnical side pressure tests, and delaying working hours, so as to improve test accuracy, The effect of simple structure and simplified auxiliary equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

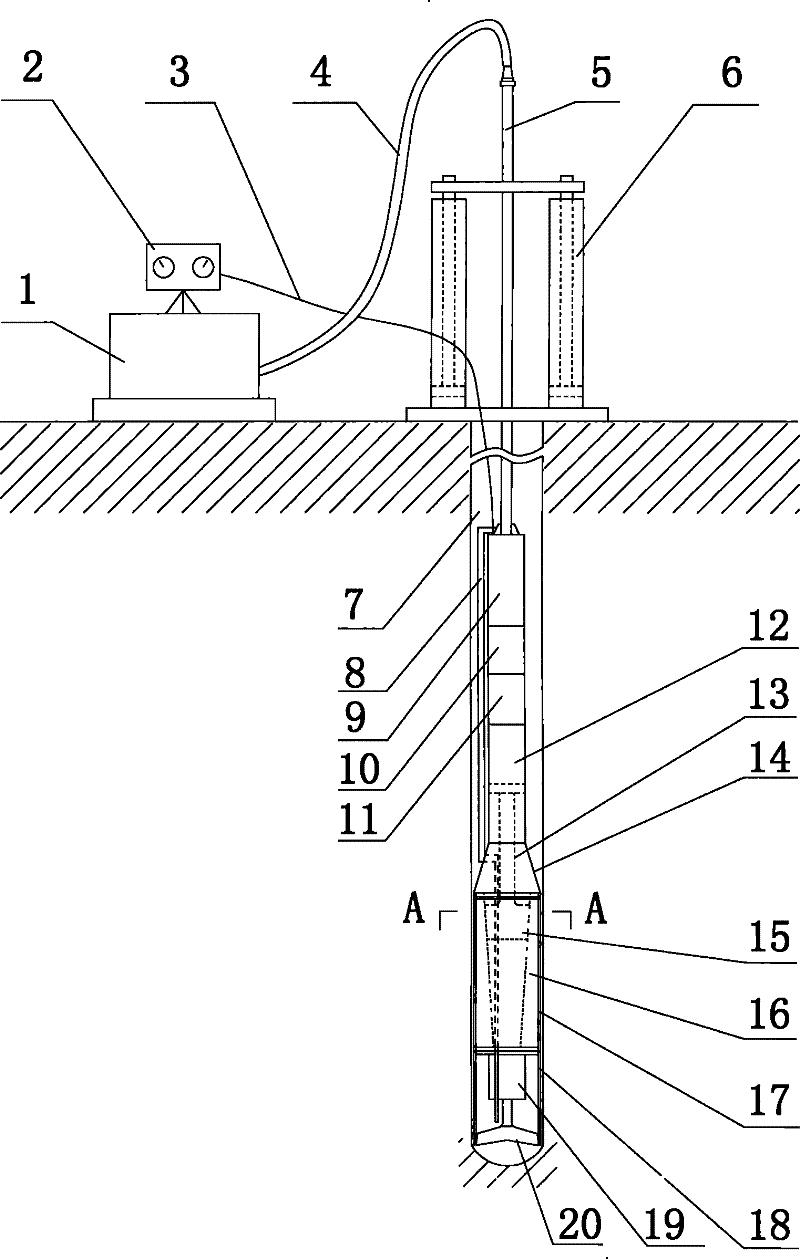

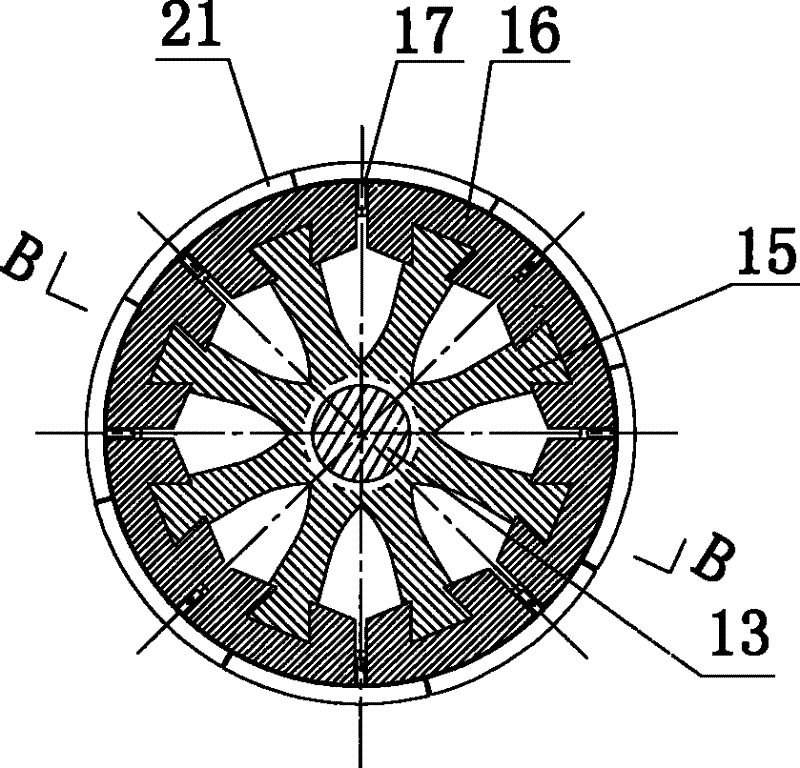

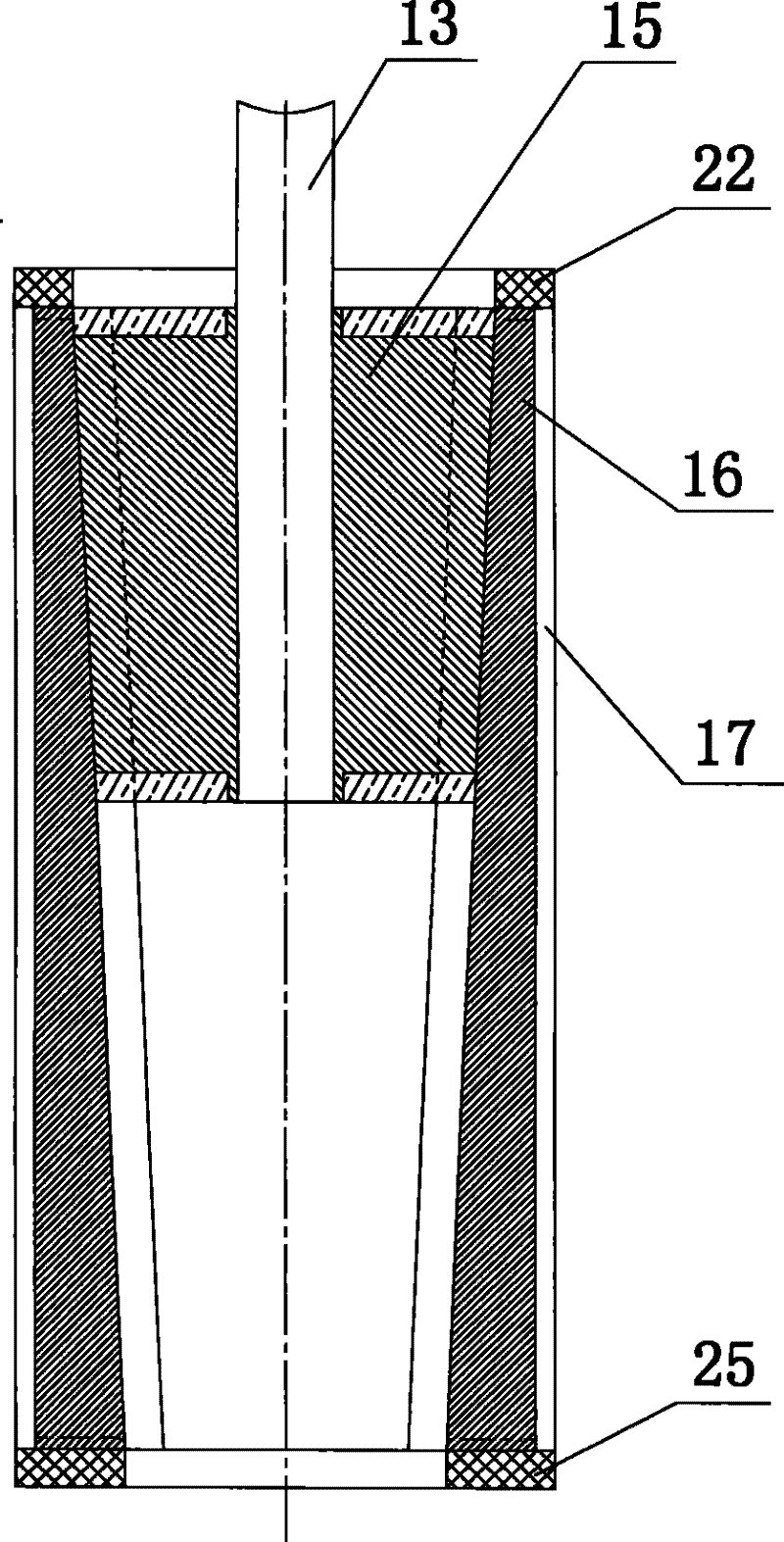

[0023] Such as figure 1 As shown, the full hydraulic self-drilling side pressure equipment, which includes a full hydraulic self-drilling side pressure instrument, mud power pump 1, data measurement and control instrument 2, shielded cable 3, high-pressure rubber hose 4, drill pipe 5, elevator 6; mud power The output end of the pump 1 is connected with the central hole of the upper end of the drill pipe 5 by the high-pressure rubber hose 4; the drill pipe 5 is set on the lifting mechanism of the elevator 6; The sealed electronic warehouse 11 is connected; when in use, the full hydraulic self-drilling side pressure instrument is set in the borehole;

[0024] Such as figure 1 As shown, the full-hydraulic self-drilling side pressure instrument includes a hydraulic power unit, a side pressure unit, and a self-drilling unit; the upper end of the hydraulic power unit is threaded with the lower end of the drill pipe 5; the lower end of the hydraulic power unit is connected to the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com