Automatic spraying conservation system for high-rise building shear wall structure

A high-rise building, automatic spraying technology, applied in building construction, construction, building materials processing and other directions, can solve the problem of shrinkage cracks on the surface of concrete, to ensure the physical strength and visual quality, good maintenance effect, avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

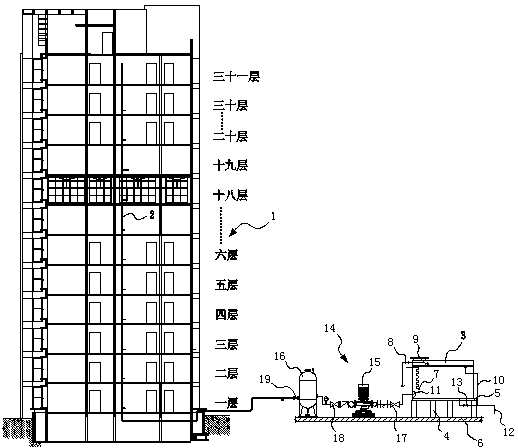

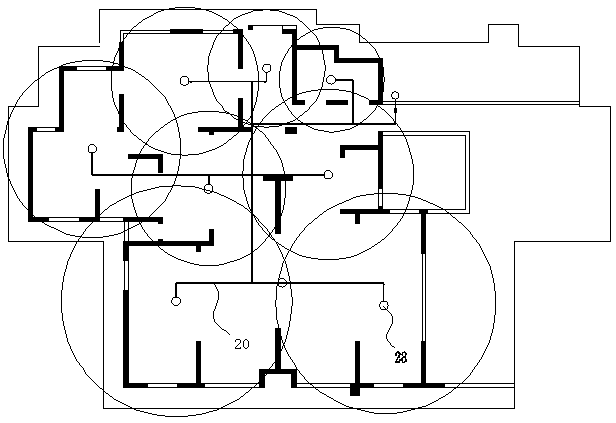

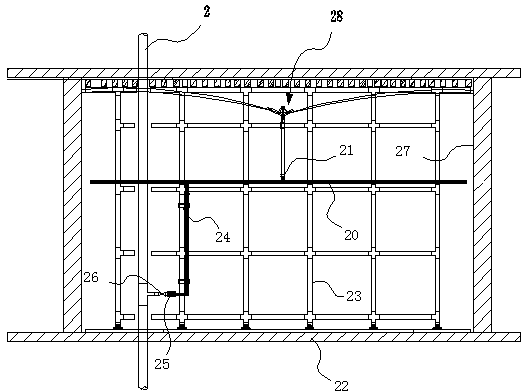

[0030] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10, a high-rise building shear wall structure automatic spray maintenance system, including a main water supply pipeline extending from the bottom of the high-rise building 1 to the top floor direction 2. The main water supply pipeline 2 is connected with a water storage tank 3 for providing water to the high-rise building 1. The water storage tank 3 is fixed to the ground 6 through the water tank legs 4 and steel brackets 5, and is installed in the water storage tank 3. There is a liquid level switch 7 for controlling the water storage capacity and a float valve 9 with a ball valve 8 linked with the liquid level switch 7 .

[0031]An overflow pipe 10 connected to the float valve 9 is arranged in the water storage tank 3 . The water storage tank 3 is provided with a filter screen 11 for filtering impurities in the water of the water storage tank 3 , and the bottom of the water storage tank 3 is connected with a water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com