Multi-column regulation type pressing die and method for forming titanium alloy double-curvature plate by using same

A titanium alloy plate and column adjustment technology, which is applied to forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient reliability, difficulty, and poor tightness, so as to improve the processing and forming effect, improve processing efficiency, shorten The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

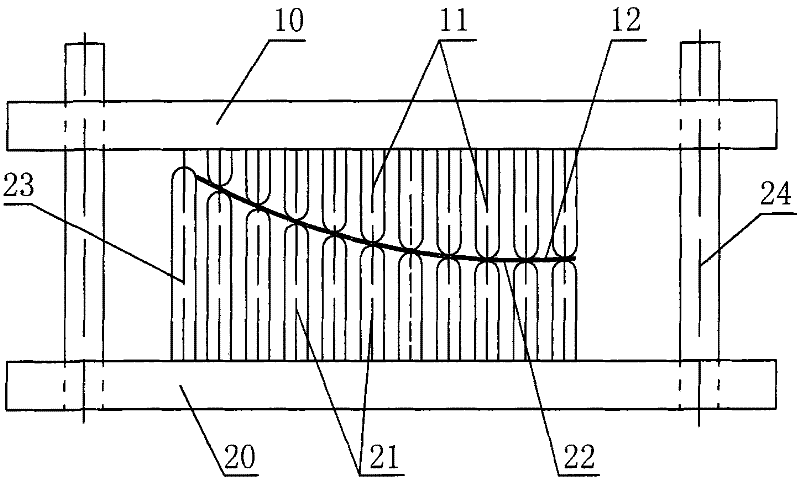

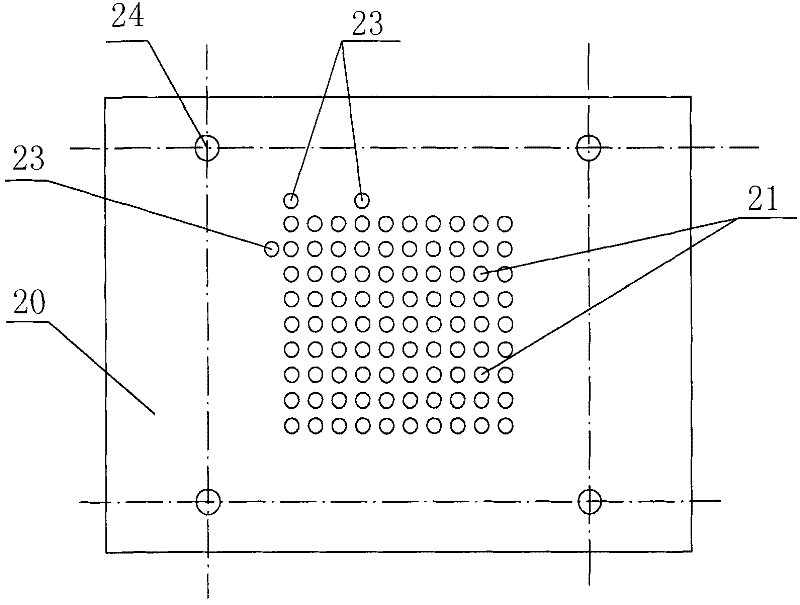

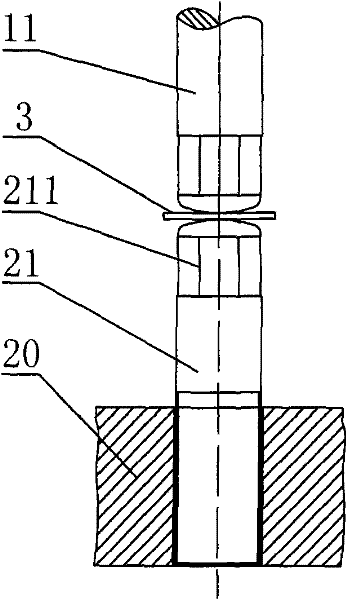

[0040] Such as Figure 4 As shown, first fix the lower die base plate 20 on the hydraulic press workbench 2, install and fix the upper die base plate 10 on the hydraulic press slider 1, and set some pads between the upper die base plate 10 and the hydraulic press slider 1 4. Separate the upper mold seat plate 10 from the hydraulic press slide block 1 by a certain distance to provide a stroke space for the relative movement between the guide post 24 and the upper mold seat plate 10 .

[0041]Coat the heat-resistant coating on the titanium alloy plate to be processed, then put the titanium alloy plate into the heating furnace and heat it to 400°C and keep it warm for 15 minutes; take out the heated and heat-preserved titanium alloy plate and immediately move it into the multi-column adjustable die, and Accurate positioning is carried out by sticking to the positioning column quickly. At the same time, a stainless steel sheet with a thickness of 2 mm is placed on both sides of th...

Embodiment 2

[0043] Same as embodiment 1, the multi-column adjustable die is installed on the hydraulic press.

[0044] Coat the titanium alloy plate to be processed with heat-resistant paint, then put the titanium alloy plate into the heating furnace and heat it to 500°C and keep it warm for 20 minutes; take out the heated and heat-preserved titanium alloy plate and immediately move it into the multi-column adjustable die, and Quickly rely on the positioning column for accurate positioning, and at the same time, place a stainless steel sheet with a thickness of 2mm on both sides of the titanium alloy plate to be processed. Press with 200 tons of pressure and keep the pressure for 10 minutes at the same time; after the pressure is released, take out the titanium alloy double curvature plate workpiece, and use the sample box to check the processing effect, and the forming effect is good.

Embodiment 3

[0046] Same as embodiment 1, the multi-column adjustable die is installed on the hydraulic press.

[0047] Coat the heat-resistant coating on the titanium alloy plate to be processed, then put the titanium alloy plate into the heating furnace and heat it to 600°C and keep it warm for 20 minutes; take out the heated and heat-preserved titanium alloy plate and immediately move it into the multi-column adjustable die, and Quickly rely on the positioning column for accurate positioning, and at the same time, place a stainless steel sheet with a thickness of 2mm on both sides of the titanium alloy plate to be processed. Press with 200 tons of pressure and keep the pressure for 10 minutes at the same time; after the pressure is released, take out the titanium alloy double curvature plate workpiece, and use the sample box to check the processing effect, and the forming effect is the best.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com