Method for determining temperature process curve of ultrahigh fly-ash content hydraulic massive concrete

A technology for concrete and fly ash is applied in the field of determining the temperature history curve of hydraulic mass concrete with ultra-high content of fly ash, which can solve the problems of difference in crack resistance, limiting the content of fly ash, and high water-to-binder ratio. Achieving the benefits of early age crack resistance and durability, wide applicability and accurate modelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

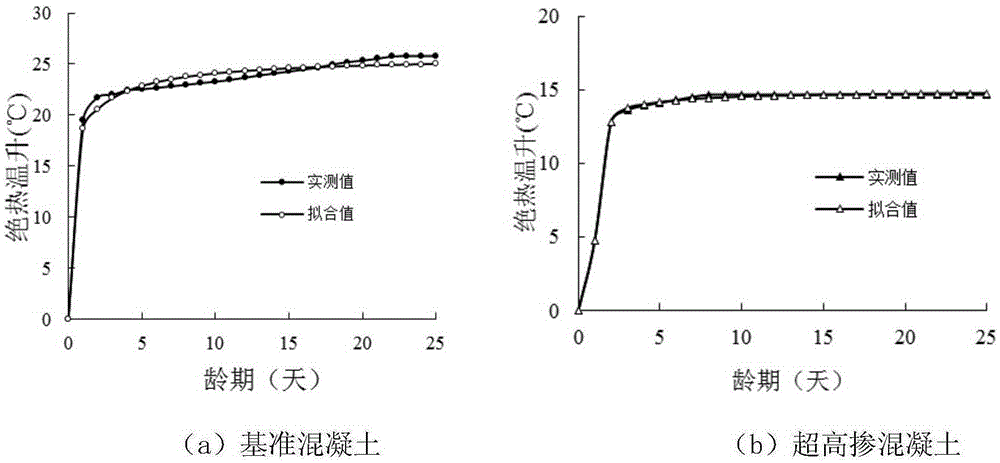

[0026] 1. Test of "Ultra High Concrete"

[0027] 1.1 Test raw materials and mix ratio

[0028] Two kinds of concrete were prepared in this test, and the "reference concrete" used the raw materials and mix ratio of the dam concrete of the double-curvature arch dam A. Two kinds of concrete with different fly ash content "reference concrete" (35% fly ash content) and "ultra-high concrete" (80% fly ash content) test raw materials are the raw materials used in double curvature arch dam A : Huaxin ordinary 42.5 Portland cement, Jingmen III grade fly ash, fine aggregate is artificial sand, coarse aggregate is artificial crushed stone with a maximum aggregate particle size of 40mm. Its mixing ratio is shown in Table 1:

[0029] Table 1 Mixing ratio of dam concrete with two different fly ash content

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com