Support-free double bent vacuum glass and manufacturing method thereof

A curved glass and vacuum glass technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve problems such as increasing the thermal conductivity of vacuum glass, glass Hertz cracks, and difficulty in improving the industrialization and mechanization of vacuum glass, etc., to achieve Excellent heat insulation and sound insulation function, high load capacity, and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings, and these drawings and descriptions are only used to illustrate the present invention.

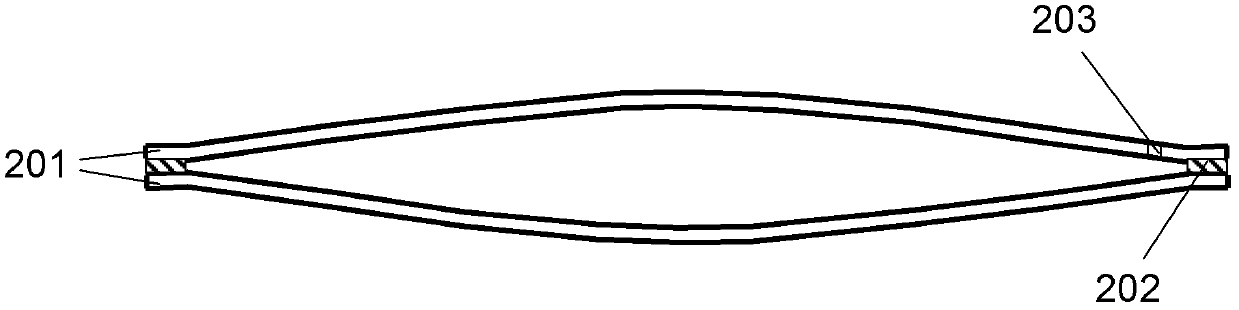

[0025] The basic structure and principle of the non-supported hyperboloid vacuum glass described in the present invention are as follows: figure 2 As shown, it includes two pieces of curved glass 201 , the two pieces of curved glass 201 are butted against the outer edges in a radian, an air gap layer is formed between them, and a sealing layer 202 of low melting point glass is formed around.

[0026] The air gap layer of the two curved glass 201 is a vacuum, which can be formed by evacuating the vacuum as a whole in the vacuum furnace when the two curved glass 201 are docked, or a suction port 203 can be set on at least one of the glasses, and the suction port 203 It communicates with the air gap layer between the two pieces of curved glass 201 , and after the two pieces of curved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com