Double-curvature rectangular reinforcing inner skin rubber hydraulic forming method

A hydroforming and inner skin technology, applied in forming tools, metal processing equipment, aircraft parts, etc., can solve the problem of high surface quality and shape accuracy requirements, loose edges of sheet materials, parts forming accuracy and poor surface quality, etc. problems, to achieve the effect of reducing the amount of manual knocking, controlling the deformation of parts, and increasing the forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

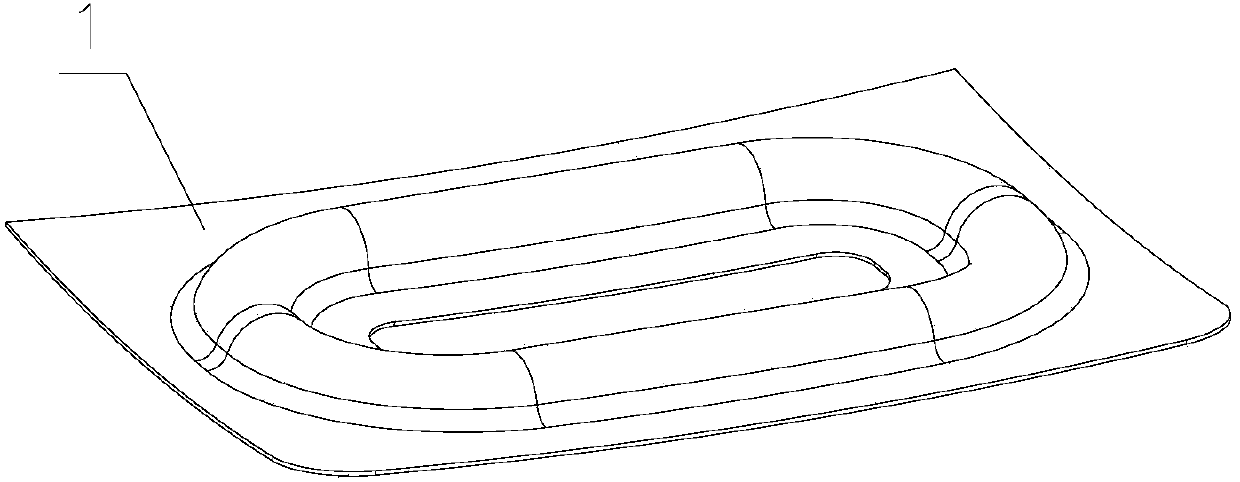

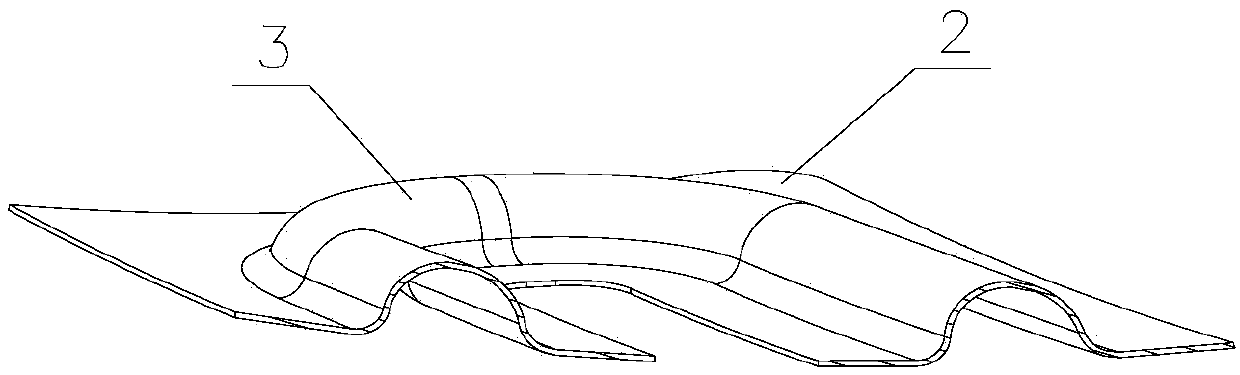

[0022] Referring to the accompanying drawings, the embodiment is the inner skin of a certain type of machine access cover, and the structure is as follows Figure 1-2 As shown, it is a double-curvature rectangular reinforced inner skin 1, the material is LY12-M-δ0.8, which is thinner and heat-treated to the CZ state. When the part is formed, shrinkage wrinkles are generated on the plane outside the corner area of the outer edge 2, and the sheet is easily cracked at the upper and lower edges R of the corner of the rib 3.

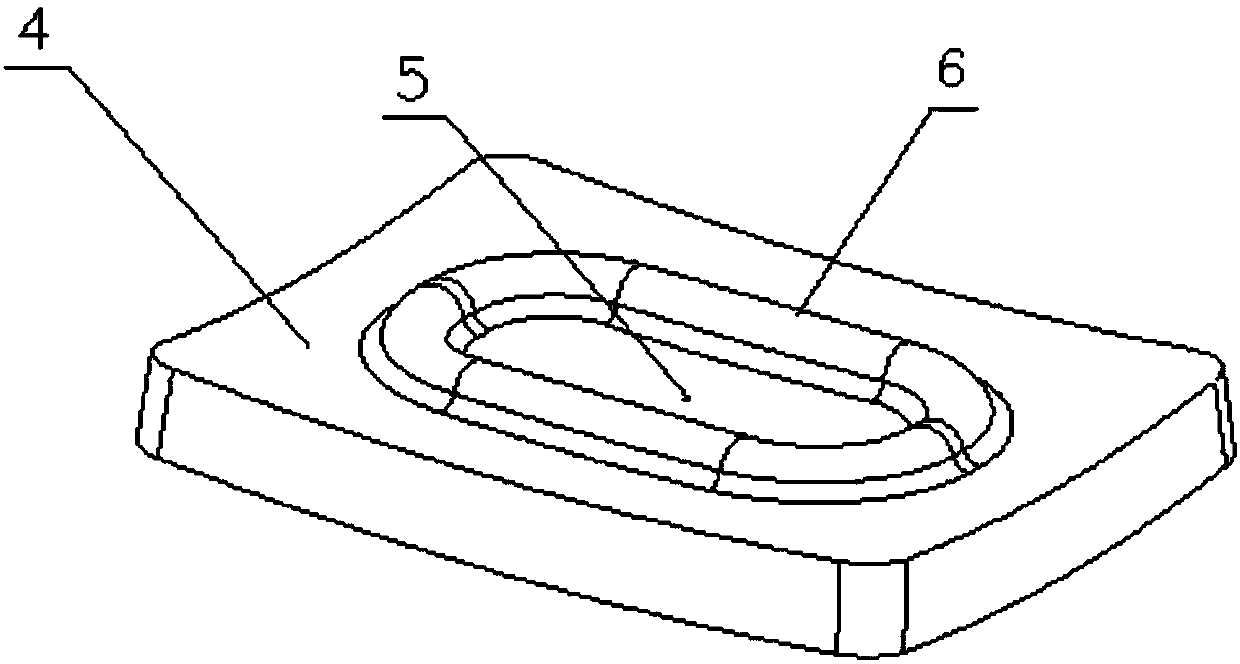

[0023] The rubber hydroforming mold structure that this application proposes is as Figure 1-4 As shown, the mold 2 is a convex mold, the mold surface is the inner mold of the inner skin 1, the height of the rib 6 of the mold is increased by 4% to 5%H, and the center of the cavity 7 is provided with an air vent 5. Inner skin forming methods such as Figure 5-7 :

[0024] Step 1. Inner skin 1 blank development calculation: The theoretical development blan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com