Method for reinforcing arch bridge with EPS Expandable Polystyrene light concrete

A lightweight concrete and concrete technology, used in bridge reinforcement, bridges, bridge materials, etc., can solve problems such as cracking and damage of bridge deck pavement, difficulty in ensuring integrity, affecting structural stress, etc., to achieve restoration or bridge bearing capacity, Good economic and environmental benefits, and the effect of improving the bearing capacity of bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

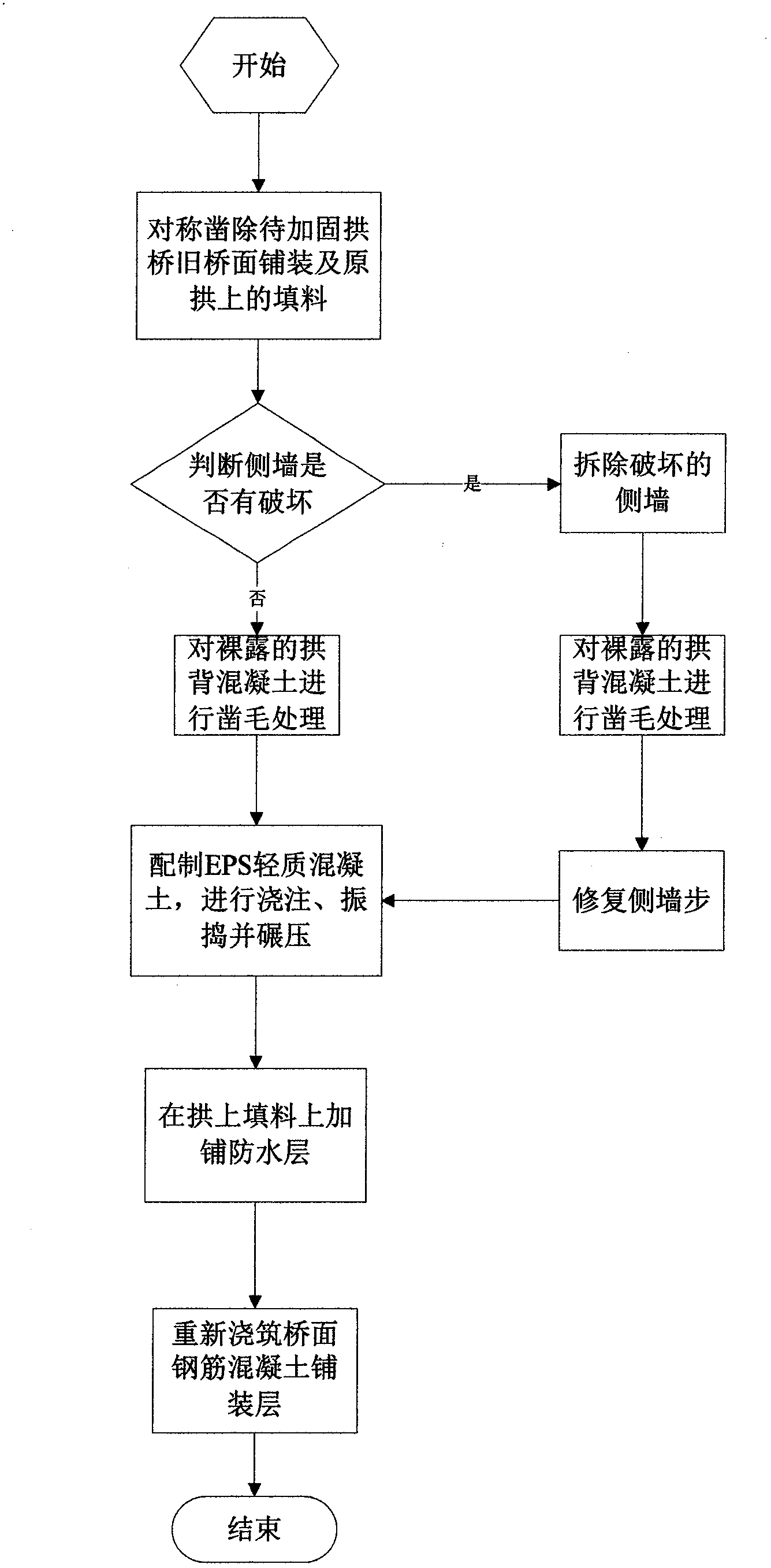

[0019] A method for reinforcing an arch bridge with EPS lightweight concrete, comprising the following steps:

[0020] a. Chisel away the old deck pavement of the arch bridge to be reinforced and the filler on the original arch;

[0021] b. Chiseling the exposed arched concrete;

[0022] c. Prepare EPS lightweight concrete, pour, vibrate and roll;

[0023] d. Re-pour the bridge deck reinforced concrete pavement layer.

Embodiment 2

[0025] A method for reinforcing an arch bridge with EPS lightweight concrete, comprising the following steps:

[0026] a. Chisel away the old deck pavement of the arch bridge to be reinforced and the filler on the original arch;

[0027] b. Demolish the damaged side wall;

[0028] c. Chiseling the exposed arched concrete;

[0029] d. Prepare EPS lightweight concrete, pour, vibrate and roll;

[0030] e. Re-pour the bridge deck reinforced concrete pavement layer.

Embodiment 3

[0032] A method for reinforcing an arch bridge with EPS lightweight concrete, comprising the following steps:

[0033] a. Chisel away the old deck pavement of the arch bridge to be reinforced and the filler on the original arch;

[0034] b. Demolish the damaged side wall;

[0035] c. Chiseling the exposed arched concrete;

[0036] d. Repair the side wall;

[0037] e. Prepare EPS lightweight concrete, pour, vibrate and roll;

[0038] f. Re-pour the bridge deck reinforced concrete pavement layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com