Testing method of integral panel parts with double curvatures

A technology of integral siding and inspection method, applied in the direction of mechanical counter/curvature measurement, etc., can solve the problems of poor coordination of tooling, inaccurate positioning, unfavorable on-site inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A method for inspecting double-curvature integral wallboard parts, characterized in that it comprises the following steps:

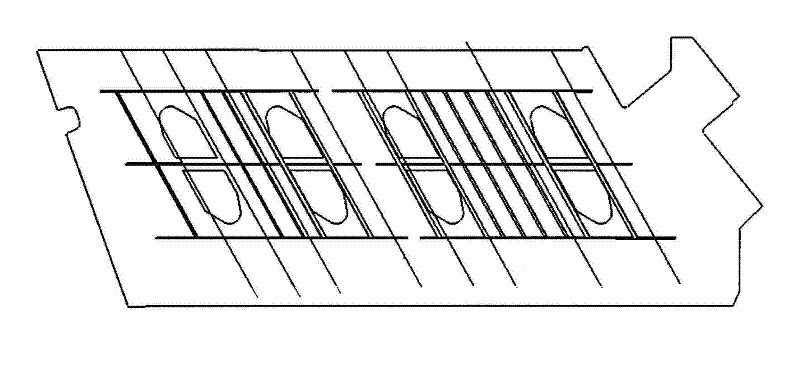

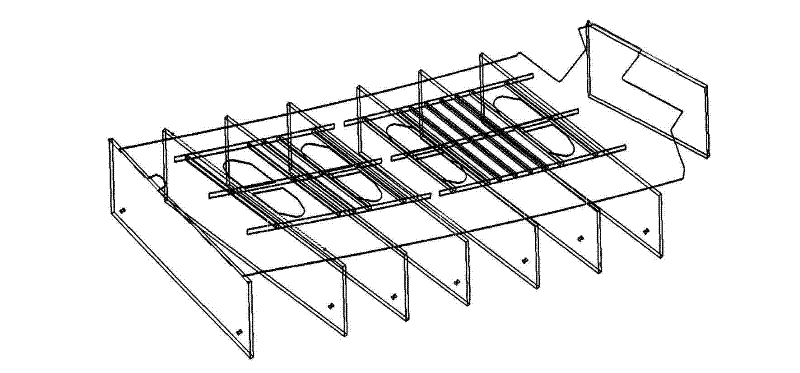

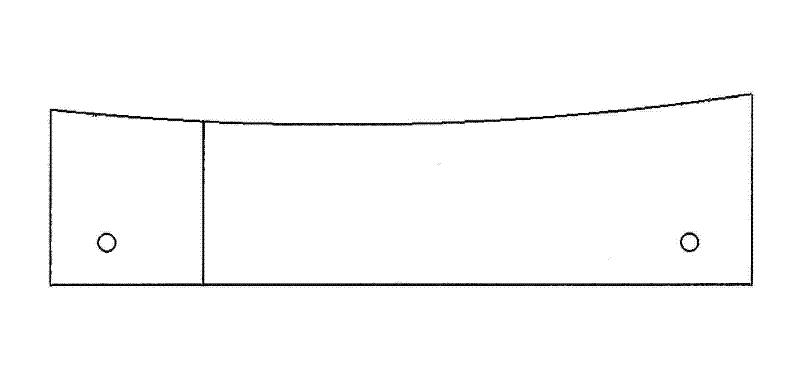

[0016] 1) if figure 1 As shown, according to the position of the main load-bearing structure of the wall panel parts and the specified position proposed by the manufacturer, it is required to draw several parallel lines perpendicular to the axis of the part; the position of the main load-bearing structure and the specified position proposed by the manufacturer are usually The location of the main load-bearing structure, including the axis of walls, ribs and long trusses, etc., the height of the rib at this location is usually the thickness of the wall plate. When forming, use this location as a reference to perform horizontal or vertical bending molding;

[0017] 2) Collect the curvature data set of each parallel line, the data set includes the horizontal and vertical dimensions, and its curvature;

[0018] 3) Make a group of inspection card boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com