Cable truss type heliostat supporting device

A technology of supporting device and heliostat, which is applied in heating device, solar thermal device, installation and other directions, can solve the problems of large amount of steel and it is difficult to guarantee the 30-year service life of the heliostat system, so as to reduce the cost of steel, The effect of shortening the adjustment time and improving the wind pressure resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] The embodiment of the invention is a cable truss type heliostat support device in a tower solar thermal power generation system.

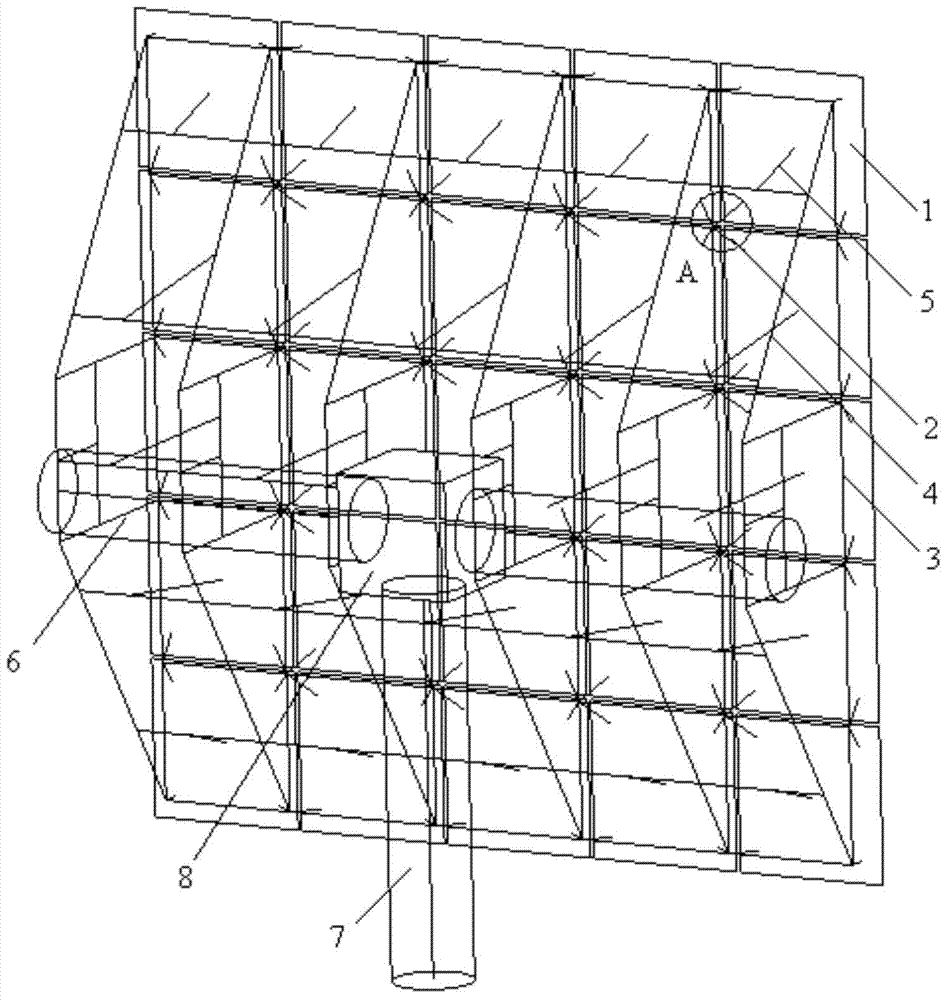

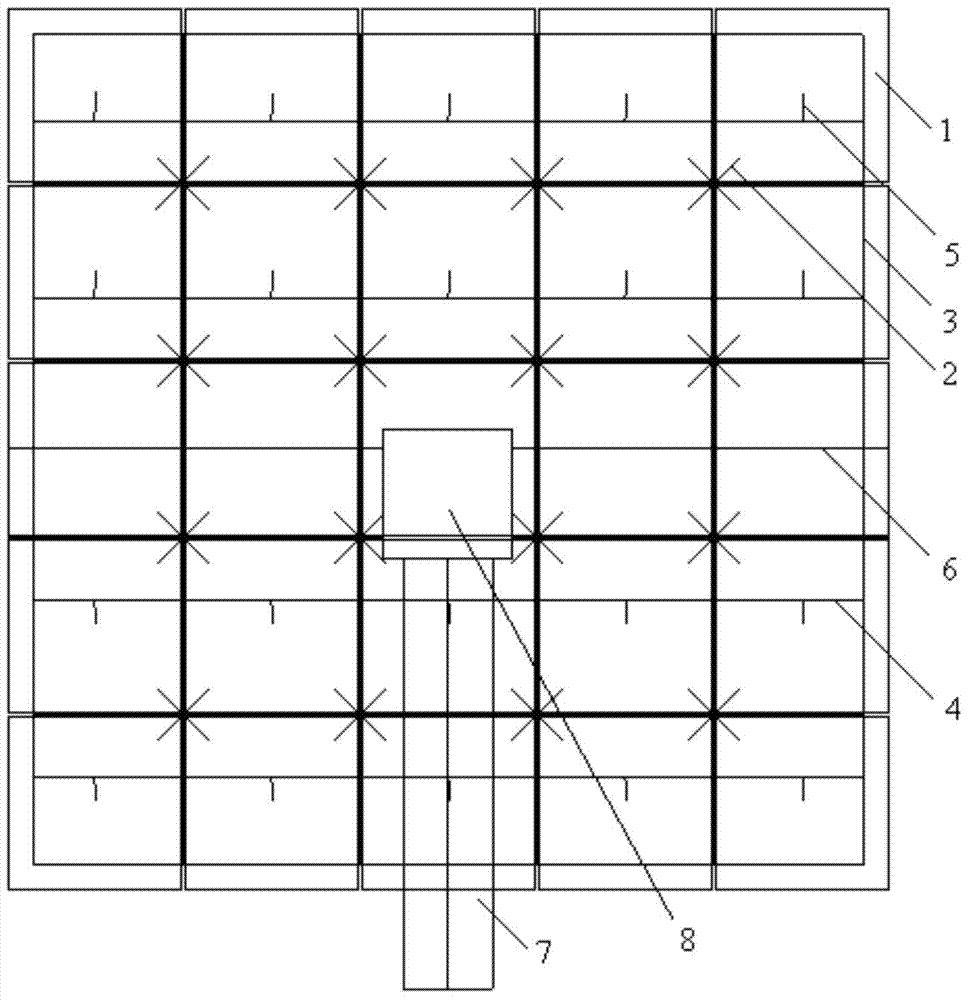

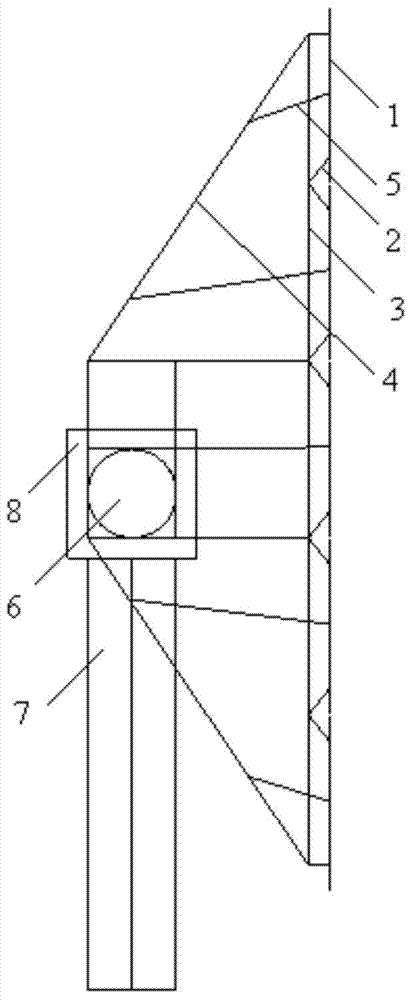

[0029] Overall structure of the present invention is as figure 1 , figure 2 and image 3 shown. The supporting device of the heliostat includes a reflector 1 , a docking system 2 , a steel cable net 3 , a truss 4 , a profiled steel cable 5 , a transverse shaft 6 , a column 7 and a driving device 8 .

[0030] The reflector 1 is composed of a plurality of sub-mirrors, and all the sub-mirrors are arranged together to form a complete plane reflector 1 . Through the connection of the docking system 2 at the corner positions and central point positions of multiple sub-mirrors of the reflector 1, the steel cable net 3 connects each sub-mirror as a whole, and the steel drag cable 5 connects the plane surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com