Unfoldable reflecting mirror body based on double-curvature negative poisson ratio honeycomb structure

A technology with negative Poisson's ratio and honeycomb structure, which is applied to mirrors and other directions, can solve the problems of aerospace mirrors that cannot be large, have high surface density, and small aperture, and achieve lightweight design, reduce stress concentration, and reduce connectors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

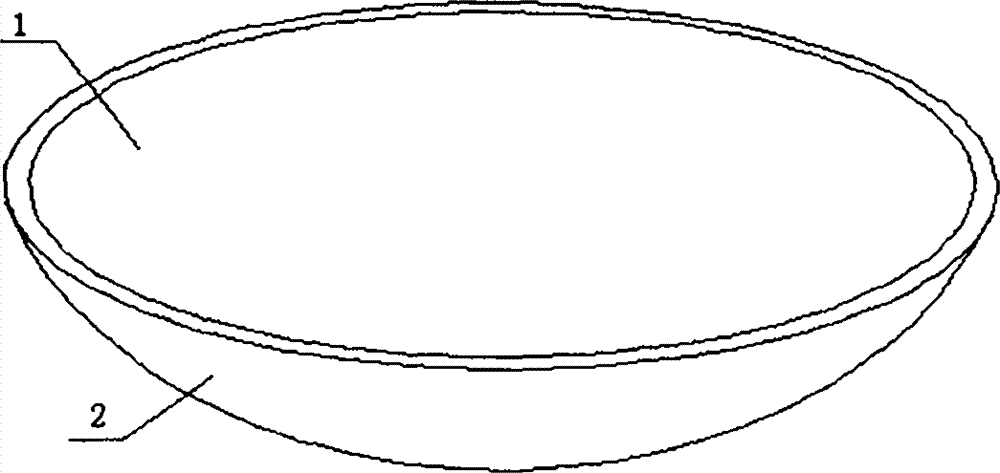

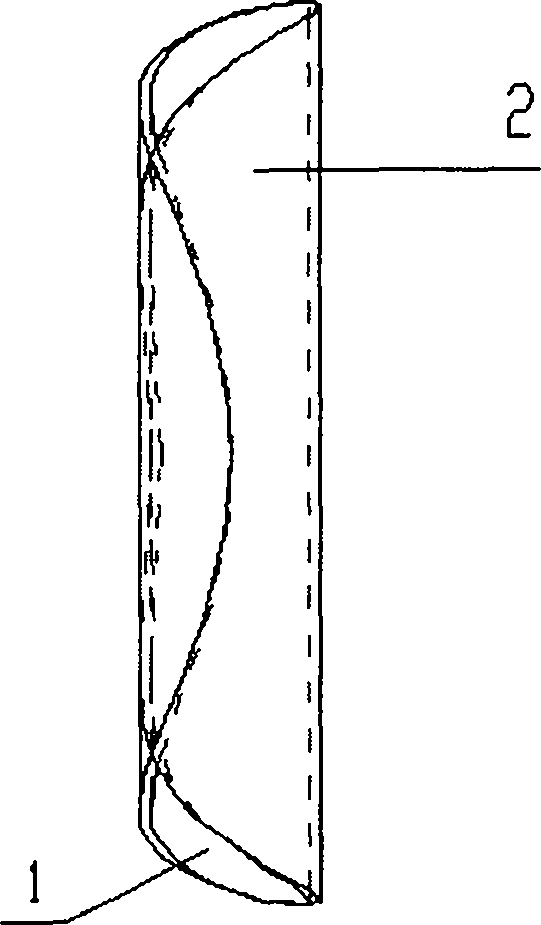

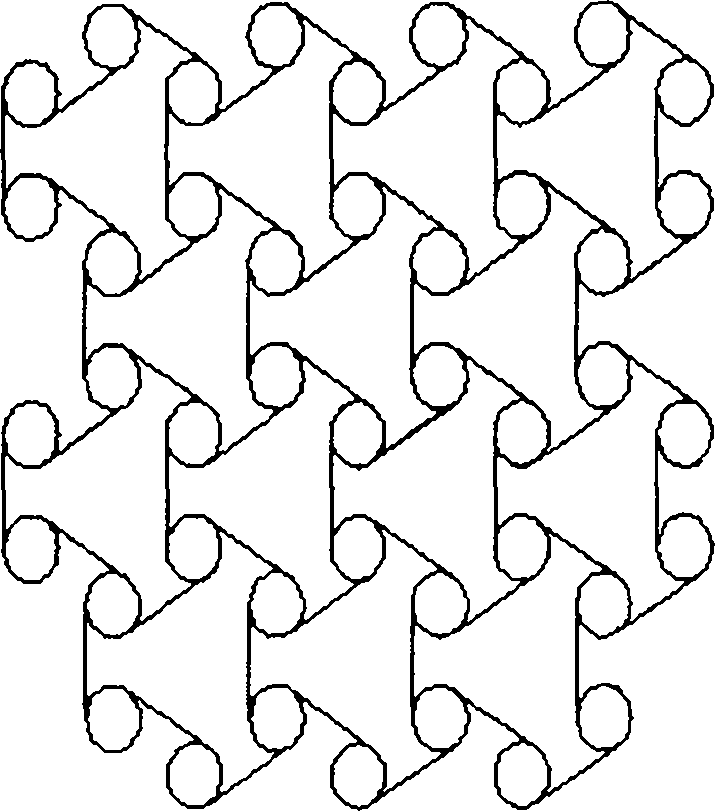

[0031] Specific implementation mode one: combine figure 1 , figure 2 , image 3 This embodiment is described. This embodiment is composed of silicon carbide or silicon carbide-based composite material pavement layer 1 and triligament antichiral honeycomb structure layer 2. The material is a shape memory composite material; the shape of the pavement layer 1 is parabolic, and the pavement layer 1 is laid on the structural layer 2. The laying layer 1 can provide a high-precision reflective surface, improve the surface smoothness of the expandable mirror body, and reduce its surface scattering rate. The structural layer 2 plays the dual role of carrying the structure and driving the unfolding of the structure.

specific Embodiment approach 2

[0032] Specific implementation mode two: combination figure 1 and Figure 4 This embodiment is described. The difference between this embodiment and the first embodiment is that the structural layer 2 is a four-ligament chiral honeycomb structure. Its composition and connection method are the same as those in Embodiment 1.

specific Embodiment approach 3

[0033] Specific implementation mode three: combination figure 1 and Figure 5 This embodiment is described. The difference between this embodiment and the first embodiment is that the structural layer 2 is a four-ligament backchiral honeycomb structure; its composition and connection method are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com