Molding method of double-curvature variable-section variable-thickness through beam

A molding method and variable cross-section technology, which is applied in the field of carbon fiber-reinforced high-temperature-resistant epoxy resin-based composite materials, can solve the problems of lack of process guidance, high requirements for shape accuracy, and difficult process control, and achieve high dimensional accuracy and comprehensive performance. , Relieve structural deformation, control the effect of inner surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

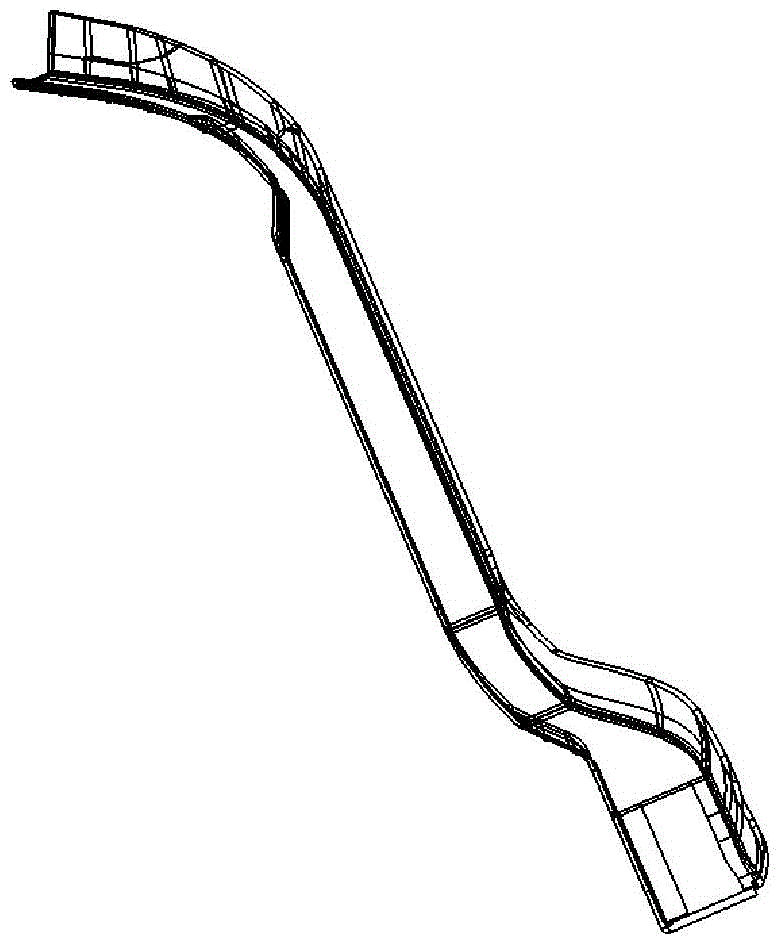

[0032] like figure 1 As shown, the beam is a double-curvature variable-section variable-thickness structure, the product length is 7500mm, and the cross-section is approximately a C-shaped cross-section. Change between 80mm-20mm, the maximum thickness of the section is 13.6mm, and the minimum thickness is 7.0mm.

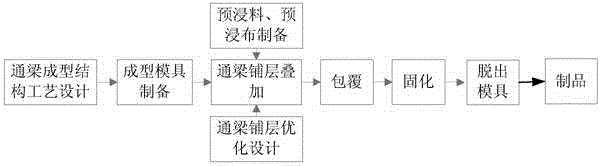

[0033] like figure 2 As shown, the forming method of the double-curvature variable-section variable-thickness through-beam of this embodiment includes the following steps:

[0034] 1) Carry out the structural process design of the double-curvature variable-section and variable-thickness through-beam, prepare a forming mold according to the structural form of the double-curvature variable-section and variable-thickness through-beam, the forming mold includes a combined female mold and a limit strip, and the combined female mold is formed by the side The stop block and the fixed block are combined, and the side block is detachably installed on the fixed block; the f...

Embodiment 2

[0049] The beam is a double-curvature variable-section variable-thickness structure with a product length of 2300mm. The C-shaped section has a maximum opening width of 100mm and a minimum opening width of 60mm. The height of one side of the C-shaped section is 110mm and the height of the other side is 40mm-20mm. The maximum thickness of the section is 10.2 mm, the minimum thickness is 6.8mm.

[0050] The molding method of the present embodiment comprises the steps:

[0051] 1) Prepare a molding die according to the structural form of a double-curvature variable-section variable-thickness beam; the molding die includes a combined female mold and a limit strip, and the combined female mold includes a detachable side stopper and a fixed block;

[0052] 2) Immerse the carbon fiber silk reinforcement and the carbon fiber cloth reinforcement into the epoxy resin glue to make hot-melt prepreg and hot-melt prepreg; the quality of the epoxy resin glue in the prepared hot-melt prepreg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com