Algan template, preparation method of algan template and semiconductor device on algan template

A technology of semiconductors and nitride semiconductors, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of uneven growth temperature of quantum well structures, inability to mass-produce high-yield epitaxial wafers, and poor wavelength uniformity of epitaxial wafers. Optimizing wavelength uniformity, achieving feasibility, and reducing the effect of accumulated stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

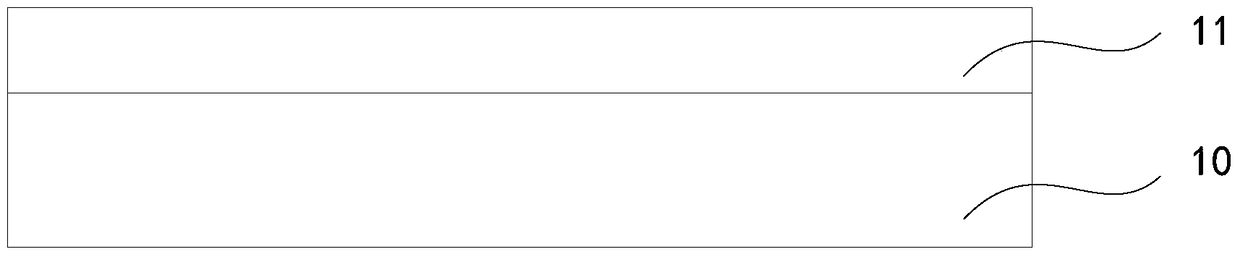

[0033] figure 2 It shows an AlGaN template provided by the first embodiment of the present invention, such as figure 2 As shown, the AlGaN template includes a substrate 10 and Al deposited on the substrate 10 1-x Ga x N crystal thin film 11, 0<x<1.

[0034] Wherein, the present embodiment does not limit the type of the substrate 10, and the substrate 10 may be Si, SiC, sapphire, ZnO, GaAs, GaP, MgO, Cu, W or SiO 2 substrate.

[0035] In realization, the Al can be deposited on the substrate by a physical vapor deposition (English: Physical Vapor Deposition, abbreviation: PVD) process or an electron beam evaporation process. 1-x Ga x N crystalline film 11. When adopting PVD process to deposit this Al on the substrate 10 1-x Ga ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com