Axisymmetric semiconductor laser bar beam combining technology and module

A semiconductor, axisymmetric technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of different coefficients of thermal expansion and contraction, high laser power density, large local temperature gradient, etc., to achieve stable energy and wavelength, reduce Damage probability, favorable effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

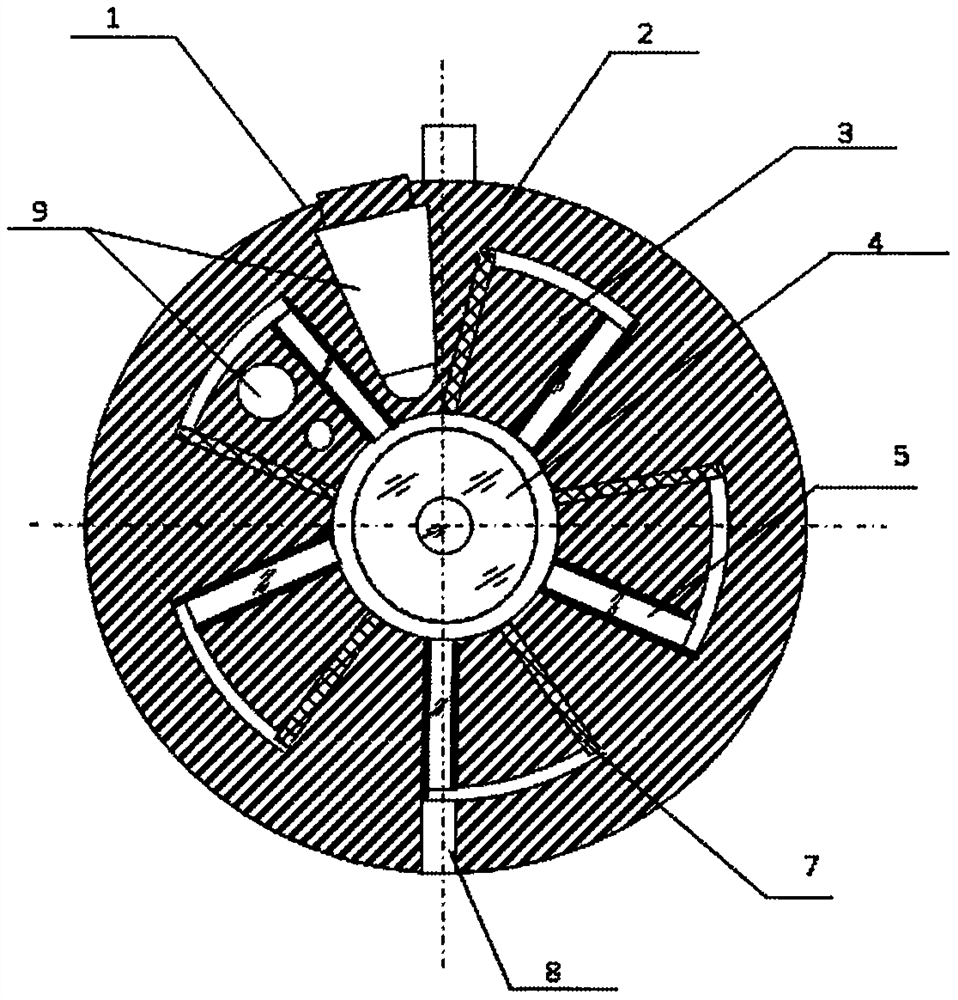

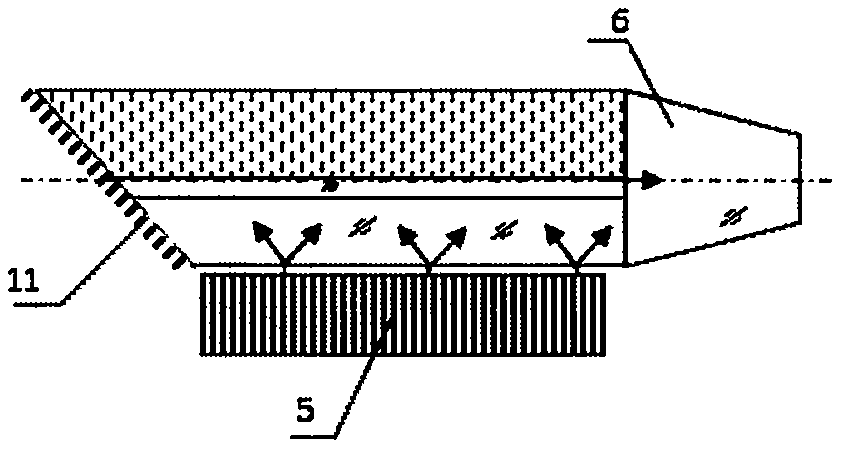

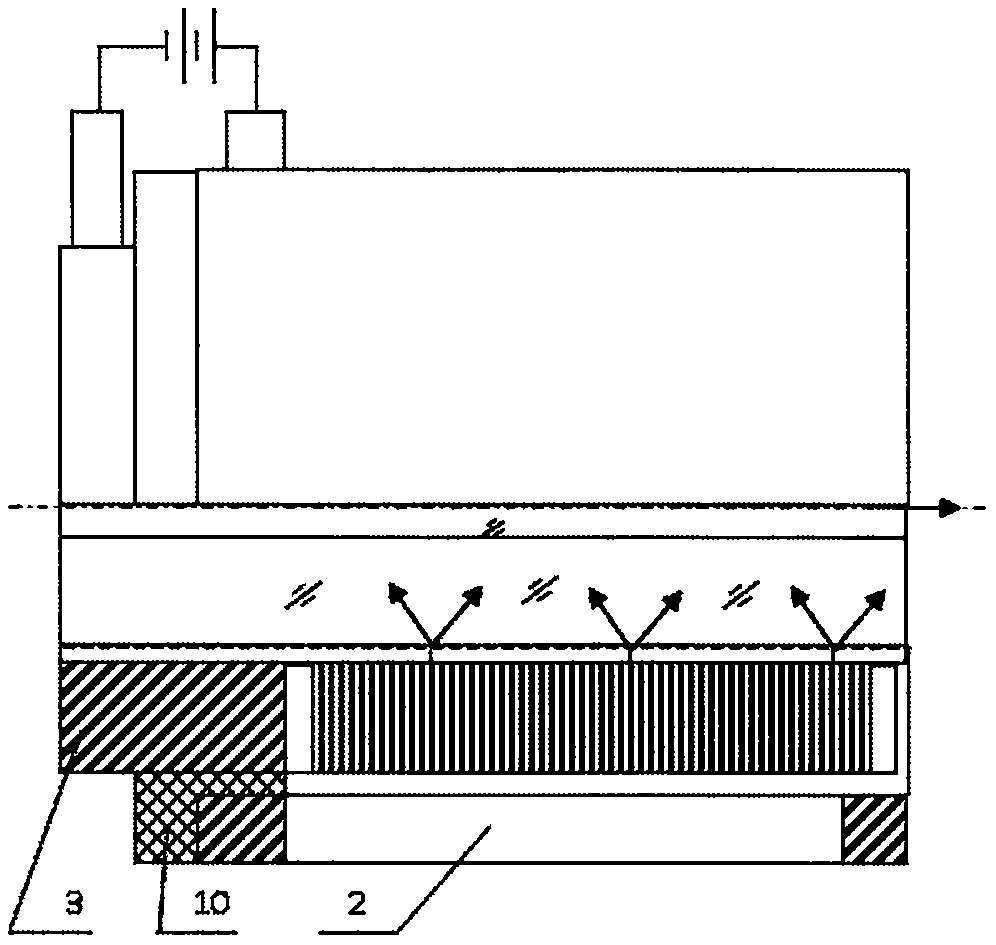

[0020] Embodiment 1 is a beam combining module 1 of a cylindrical symmetrical structure with an internal gear 2 and an external gear 3 geared together to clamp a semiconductor laser bar 5. The number of teeth of the internal gear 1 and the external gear 2 is equal and is an odd number of Q, The inner gear 2 and the outer gear 3 preferably have 5 teeth, the inner gear 1 and the outer gear 2 are preferably metal gears, the material is tungsten copper alloy, the outer diameter of the inner gear 2 is 10 mm, the inner diameter of the inner gear 2 is 1 mm, and the outer The diameter of the outer circle of the gear 3 is 6 mm, the diameter of the inner circle of the outer gear 3 is 1 mm, the inner wall of the inner gear 2 is a cylinder with 5 sides located in the radial direction of the cylinder, and the tooth tops of the inner gear 2 are not chamfered The outer gear 3 is one end of the cylinder in the axial direction, and there are 5 side surfaces located in the radial direction of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com