Supersonic shot-peening forming method for single or double curvature integral panels

An integral wall plate and shot peening forming technology, applied in abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve the problems of complex structure of shot peening system, rough metal plate, affecting surface quality, etc., to achieve strong operability, Good molding accuracy and good surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

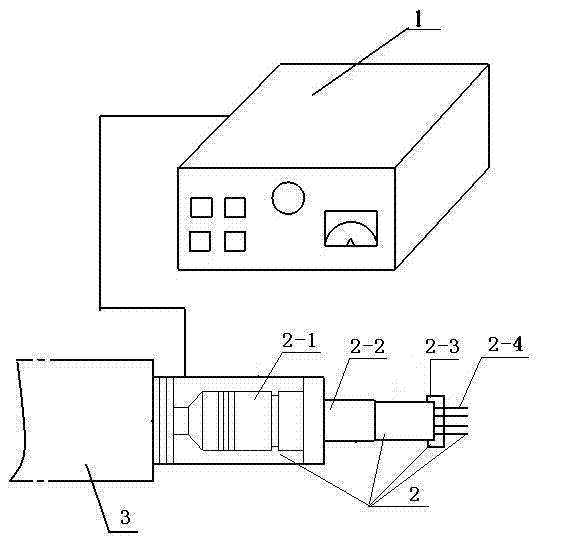

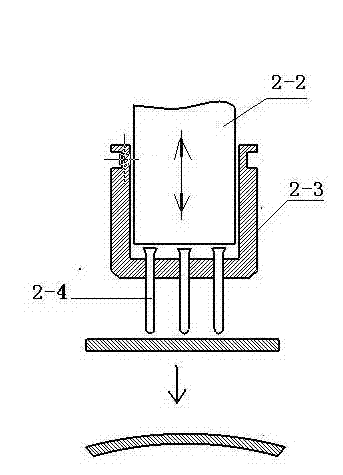

[0028] The ultrasonic shot-peening forming method of tapered integral wall plate, it comprises the following steps: utilize ultrasonic shot-peening equipment, such as figure 1 with figure 2 As shown, the described ultrasonic shot peening equipment includes an ultrasonic generator 1 and an impact gun 2, and the described impact gun 2 is installed on the side of the CNC machine tool spindle 3, and the described impact gun 2 includes an ultrasonic transducer 2-1, and The horn 2-2 connected to the ultrasonic transducer 2-1, the vibration tool head 2-3 connected with the horn 2-2-, and the striker 2-4 installed on the vibration tool head 2-3;

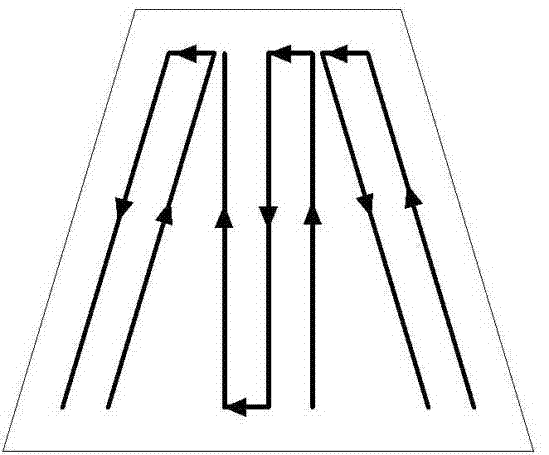

[0029] Before the ultrasonic shot peening, use the striker 2-4 to perform tool setting, and then set the forming trajectory of the tapered integral wall plate according to the shape requirements of the tapered integral wall plate, such as image 3 As shown, and on the CNC machine tool, the numerical control program corresponding to the for...

Embodiment 2

[0033] The ultrasonic shot-peening forming method of convex peak-shaped integral wall plate, it comprises the following steps: utilize ultrasonic shot-peening equipment, such as figure 1 with figure 2 As shown, the described ultrasonic shot peening equipment includes an ultrasonic generator 1 and an impact gun 2, and the described impact gun 2 is installed on the side of the CNC machine tool spindle 3, and the described impact gun 2 includes an ultrasonic transducer 2-1, and The horn 2-2 connected to the ultrasonic transducer 2-1, the vibration tool head 2-3 connected to the horn 2-2, and the striker 2-4 installed on the vibration tool head 2-3;

[0034]Before the ultrasonic shot peening, the striker 2-4 is used for tool setting, and then the forming trajectory of the convex-shaped integral wall panel is set according to the requirements of the forming shape of the convex-shaped integral wall panel, such as Figure 4 shown, and on the numerically controlled machine tool, the...

Embodiment 3

[0038] The ultrasonic shot-peening forming method of the curved integral wall plate comprises the following steps: utilizing ultrasonic shot-peening equipment, such as figure 1 and figure 2 As shown, the described ultrasonic shot peening equipment includes an ultrasonic generator 1 and an impact gun 2, and the described impact gun 2 is installed on the side of the CNC machine tool spindle 3, and the described impact gun 2 includes an ultrasonic transducer 2-1, and The horn 2-2 connected to the ultrasonic transducer 2-1, the vibration tool head 2-3 connected to the horn 2-2, and the striker 2-4 installed on the vibration tool head 2-3;

[0039] Before the ultrasonic shot peening, the striker 2-4 is used for tool setting, and then the forming track of the bent integral wall plate is set according to the requirements of the formed shape of the bent integral wall plate, such as Figure 5 and Image 6 As shown, and on the CNC machine tool, the numerical control program correspon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com