Method for preparing nickle lithium manganate material for lithium ion power battery anode

A technology for lithium ion batteries and positive electrode materials, which is applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of unfavorable application, complicated steps, and high cost, and achieve the effects of low production cost, simple preparation method, and large discharge capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

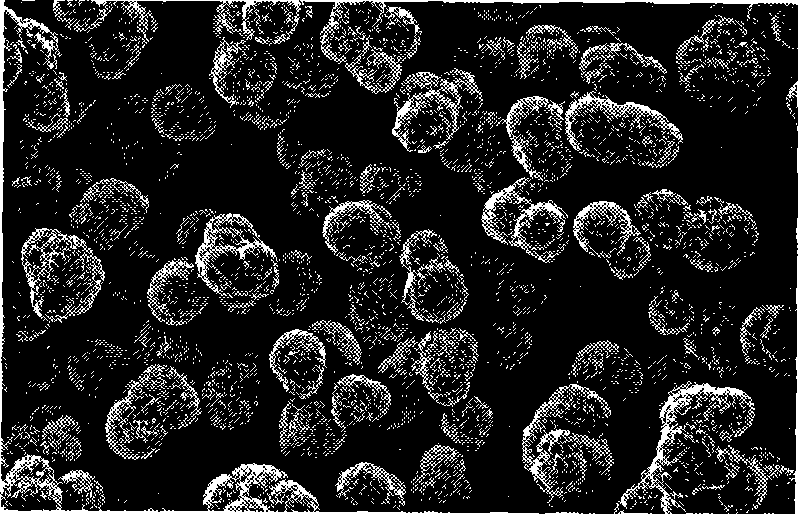

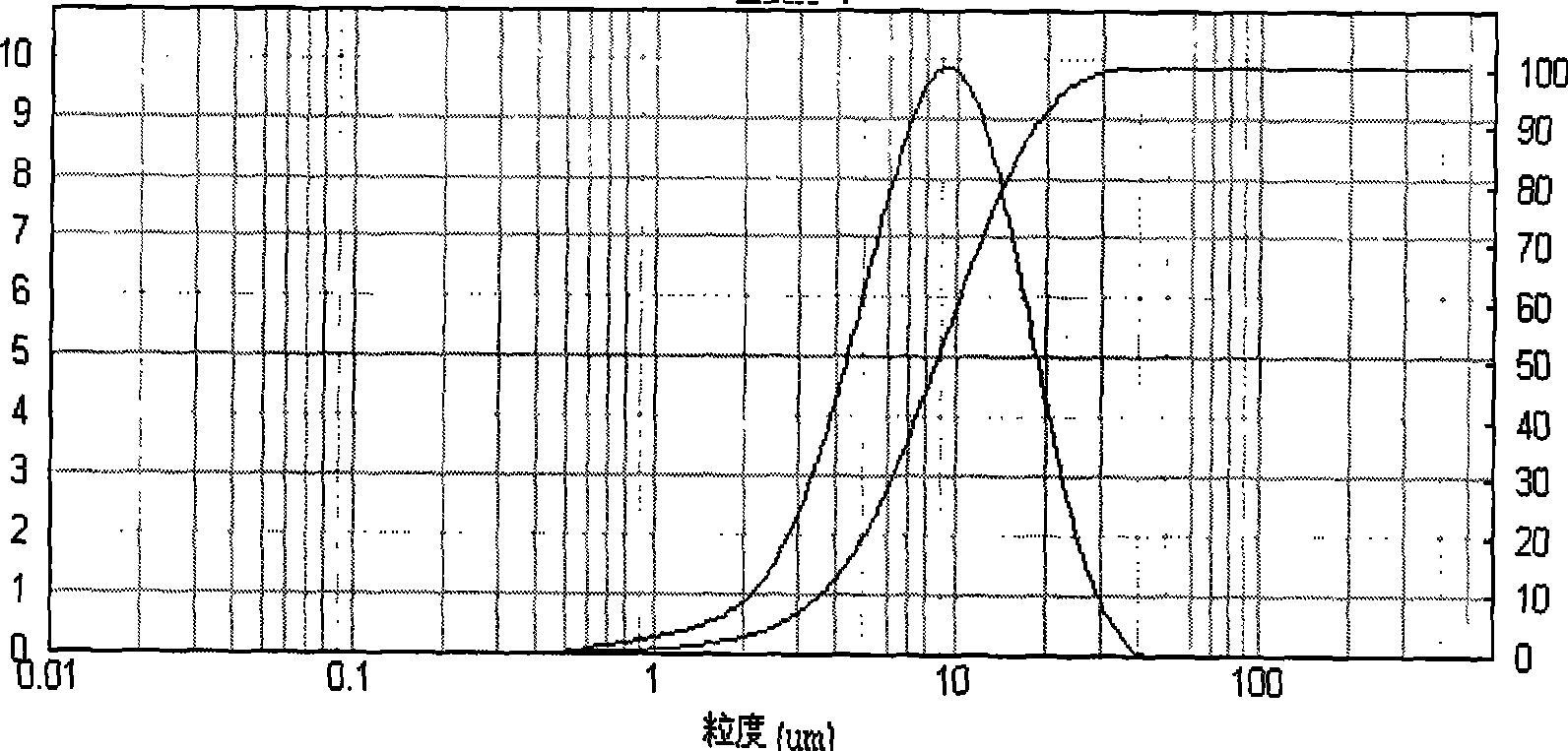

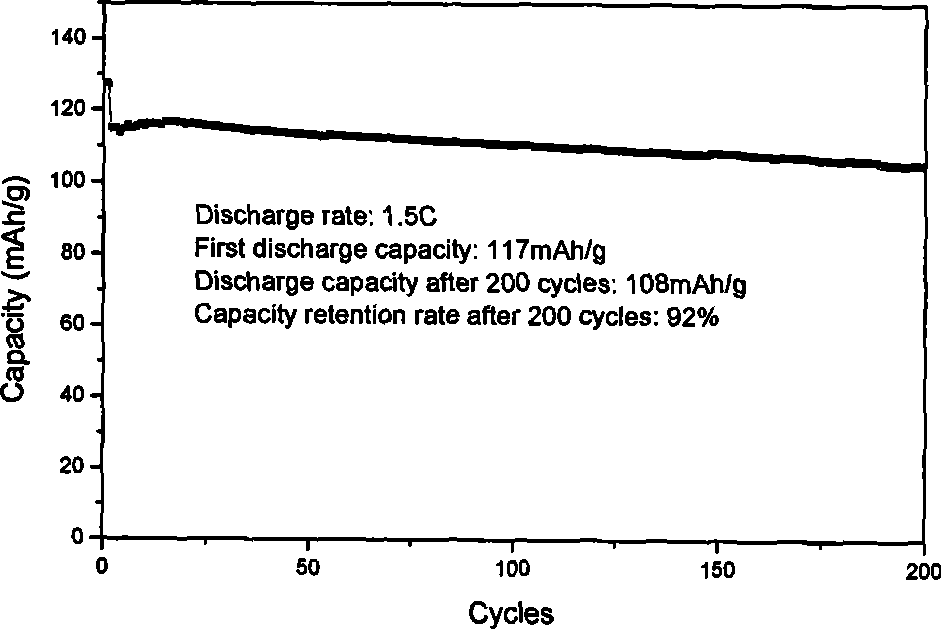

Embodiment 1

[0018] Weigh nickel nitrate and manganese nitrate with a Ni:Mn molar ratio of 0.5:1.5, mix them and add deionized water to make a 0.5mol / L solution. The obtained solution is dried with a high-speed centrifugal drying sprayer to obtain a mixed powder, and the feeding solution speed is 40ml / min; the gas flow rate of the nozzle is controlled by the pressure of compressed air, and the pressure is controlled at 0.4MPa; the air inlet temperature is 310°C, and the outlet temperature is 110°C. ℃. Weigh the mixed powder and lithium salt at a molar ratio of 2:1.06, weigh the mixed powder and lithium carbonate, mix them by ball milling, heat up at a rate of 10°C / min in an oxygen atmosphere, and calcinate at a constant temperature of 850°C for 5 hour, and then directly cool down to room temperature at a rate of 20°C / min, and after grinding, LiNi, a positive electrode material for lithium-ion power batteries with excellent electrochemical performance, can be prepared. 0.5 mn 1.5 o 4 . ...

Embodiment 2

[0020] Weigh nickel sulfate and manganese sulfate with a Ni:Mn molar ratio of 0.2:1.8, mix them and add deionized water to make a 1.0mol / L solution. The obtained solution was dried with a high-speed centrifugal drying sprayer to obtain a mixed powder, and the feed solution speed was 30ml / min; the gas flow rate of the nozzle was controlled by the pressure of compressed air, and the pressure was controlled at 0.4MPa; the air inlet temperature was 310°C, and the outlet temperature was 110°C. ℃. Weigh the mixed powder and lithium salt at a molar ratio of 2:1.06, weigh the mixed powder and lithium carbonate, mix them by ball milling, heat up at a rate of 10°C / min in an oxygen atmosphere, and calcinate at a constant temperature of 800°C for 8 Hours, then cool down to room temperature with the furnace, and LiNi can be prepared after grinding 0.2 mn 1.8 o 4 .

Embodiment 3

[0022] Weigh nickel nitrate and manganese nitrate with Ni:Mn molar ratio of 0.7:1.3, mix and add deionized water to make a 0.8mol / L solution. The obtained solution was dried with a high-speed centrifugal drying sprayer to obtain a mixed powder, and the feed solution speed was 30ml / min; the gas flow rate of the nozzle was controlled by the pressure of compressed air, and the pressure was controlled at 0.4MPa; the air inlet temperature was 310°C, and the outlet temperature was 110°C. ℃. Weigh the mixed powder and lithium salt at a molar ratio of 2:1.06, weigh the mixed powder and lithium sulfate, mix them by ball milling, heat up at a rate of 10°C / min in an oxygen atmosphere, and calcinate at a constant temperature of 850°C for 5 hours, and then directly cool down to room temperature at a rate of 20°C / min, and LiNi can be prepared after grinding 0.2 mn 1.8 o 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com