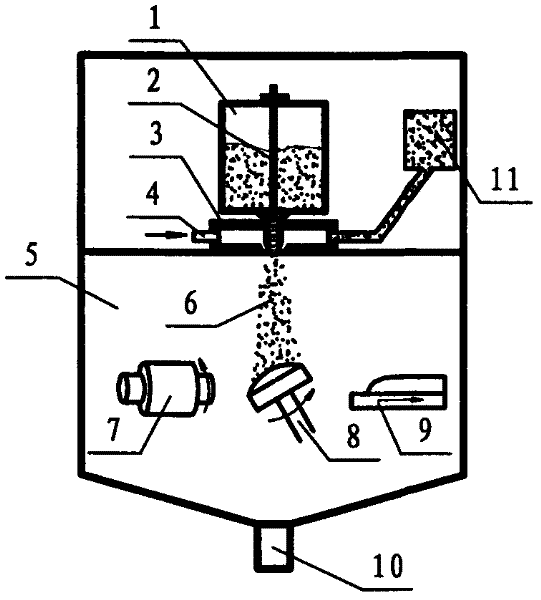

Method and system for preparing particle-reinforced metal-based composite material through injection molding

A particle enhancement and spray forming technology, applied in the field of enhanced particle generation and molten metal atomization, can solve the problems of large consumption of inert gas, small diameter of powder conveying pipe, affecting the uniform distribution of enhanced particles, etc., to reduce the consumption of inert gas , The particle size distribution is narrow, and the effect of improving the atomization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

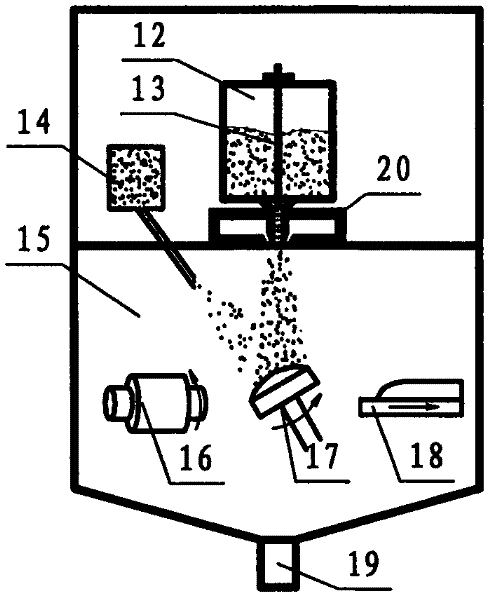

[0034] Step 1: Preparation of reinforced ceramic particles. Mix the raw materials according to the ratio of 50%Al+49%CuO+1%Mg (mass fraction), and carry out reaction ball milling on a vacuum ball mill for 10 hours, and Al and CuO will chemically form Al with a diameter of 15 μm 2 o 3 ceramic particles;

[0035] Step 2: the Al prepared in the first step 2 o 3 The ceramic particles are transferred to the powder bin 11 in the vacuum chamber 5;

[0036] Step 3: Put the 7075 alloy in the crucible, and evacuate the vacuum chamber to less than 50Pa. Turn on the intermediate frequency heating equipment to heat the matrix alloy to a molten state and make it have a superheat of 100°C;

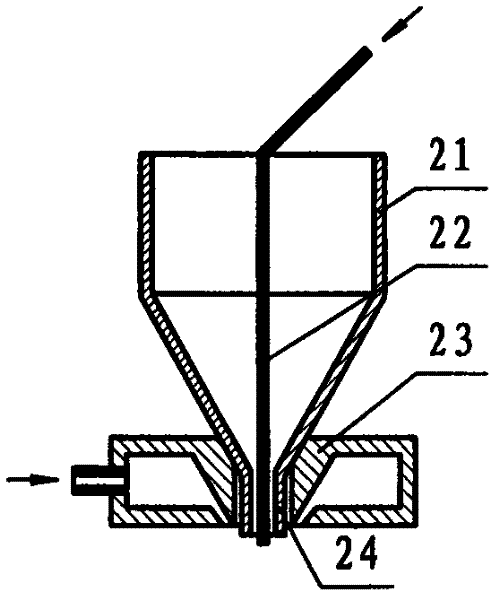

[0037] Step 4: Al 2 o 3 The ceramic particles enter the nozzle 3 and are accelerated by inert gas mixing, and fly out from the outlet of the nozzle 3. The inert gas mixed with the ceramic particles is used as the atomizing medium to flow down through the guide tube, and the molten 7075 alloy is so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com