255 DEG C superhigh temperature resistant water-based drilling fluid and construction process thereof

A water-based drilling fluid and ultra-high temperature technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve the technical bottleneck of water-based drilling fluid, difficult control of rheology and fluid loss, and high temperature stability In order to avoid the problems of poor fluidity and other problems, the effects of avoiding well wall collapse, controllable fluid loss, and good ultra-high temperature lubricity are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

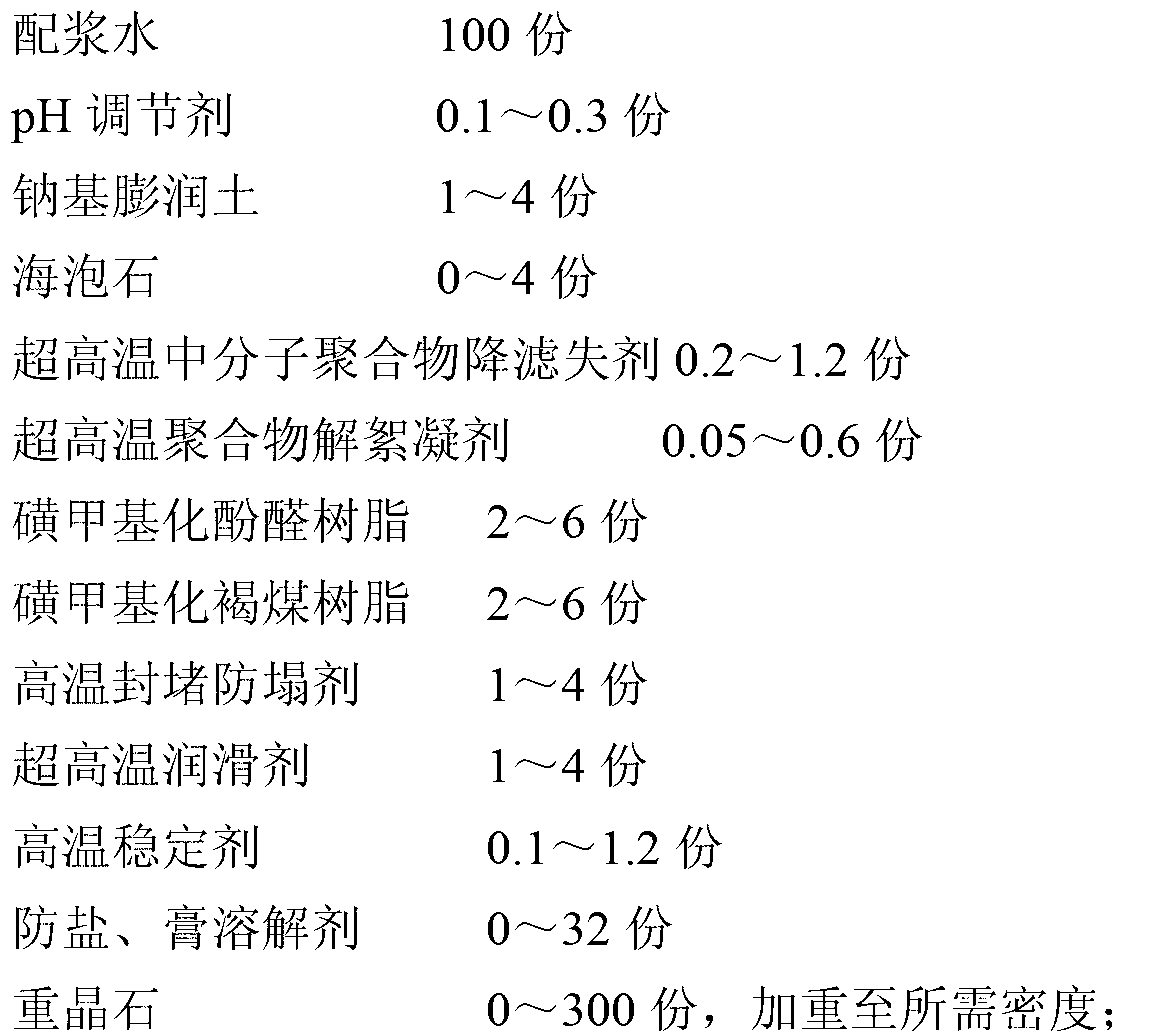

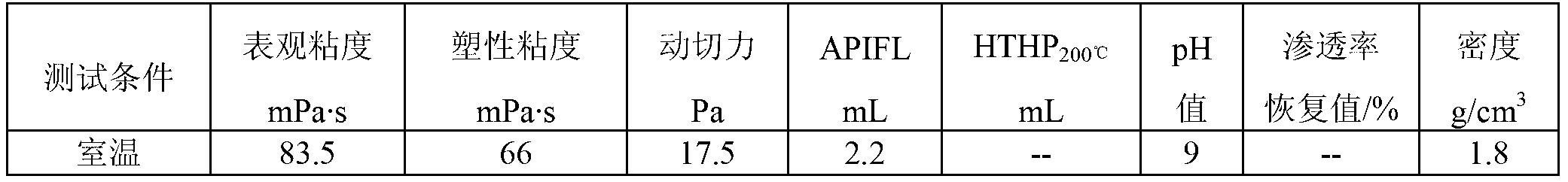

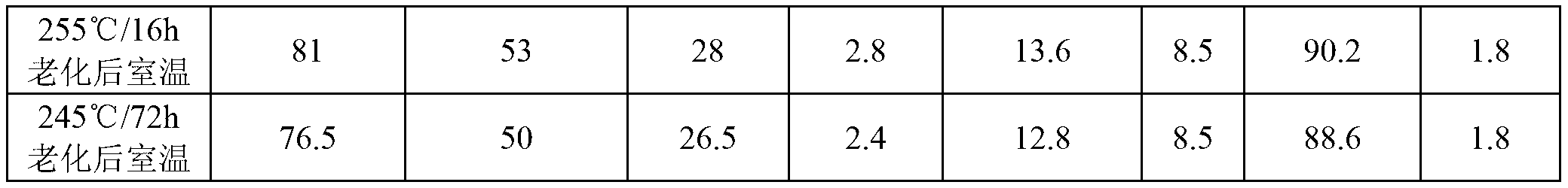

[0057] 1.1 Formula: 400mL mixing water + 0.6g sodium carbonate + 0.4g sodium hydroxide + 8g sodium bentonite + 8g sepiolite + 1.2g ultra-high temperature medium molecular polymer fluid loss reducer + 12g sulfomethylated phenolic resin + 12g sulfomethylated lignite resin + 8g ultra-high temperature plugging and anti-slump agent + 0.8g ultra-high temperature polymer deflocculant + 2g sodium sulfite + 8g extreme pressure lubricant + 68g sodium chloride calcium chloride compound salt (sodium chloride: Calcium chloride = 6:1) + high-purity barite aggravated to a density of 1.8g / cm 3 .

[0058] 1.2 Preparation method: add 0.6g sodium carbonate and 0.4g sodium hydroxide to 400mL slurry mixing water, add 8g sodium bentonite and 8g sepiolite under stirring, stir at 12000rpm for 20 minutes at high speed, and seal the prewatering at 25℃±2℃ After 24 hours of melting to obtain the base slurry; under high-speed stirring at 12000rpm, add ultra-high temperature medium molecular polymer fluid...

Embodiment 2

[0069] 2.1 Formula: 400mL mixing water + 0.8g sodium carbonate + 0.4g sodium hydroxide + 16g sodium bentonite + 2.4g ultra-high temperature medium molecular polymer fluid loss additive + 16g sulfomethylated phenolic resin + 16g sulfomethylated Lignite resin + 12g ultra-high temperature plugging and anti-slumping agent + 0.4g ultra-high temperature polymer deflocculant + 1.6g ascorbyl palmitate + 8g white oil + high-purity barite weighted to a density of 1.35g / cm 3 .

[0070] 2.2 Preparation method: Add 0.8g sodium carbonate and 0.4g sodium hydroxide to 400mL slurry preparation water, add 16g sodium-based bentonite under stirring, stir at high speed for 20 minutes, and pre-hydrate in airtight at 25°C±2°C for 24 hours to obtain the base Under high-speed stirring, add ultra-high temperature medium molecular polymer fluid loss reducer, sulfomethylated phenolic resin, sulfomethylated lignite resin, ultra-high temperature plugging anti Collapsing agent, ultra-high temperature polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com