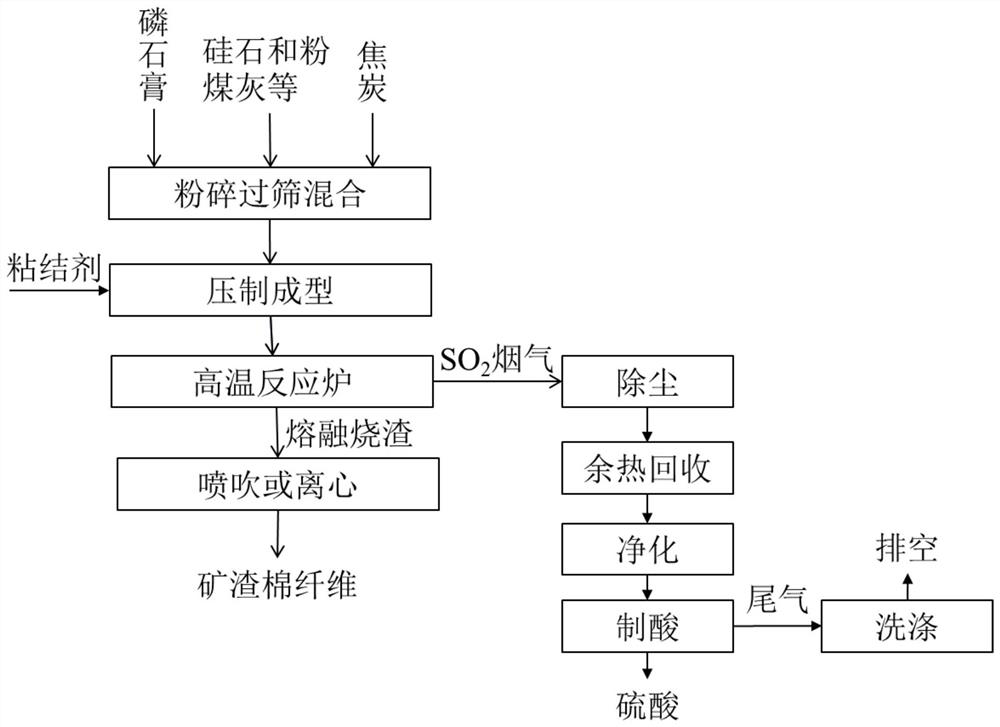

Method for preparing sulfuric acid and co-producing slag cotton fiber from high-impurity phosphogypsum

A technology made of slag cotton fiber and gypsum, which is applied in chemical instruments and methods, sulfur compounds, manufacturing tools, etc., to achieve the effects of economic and ecological environmental benefits, reducing impact and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

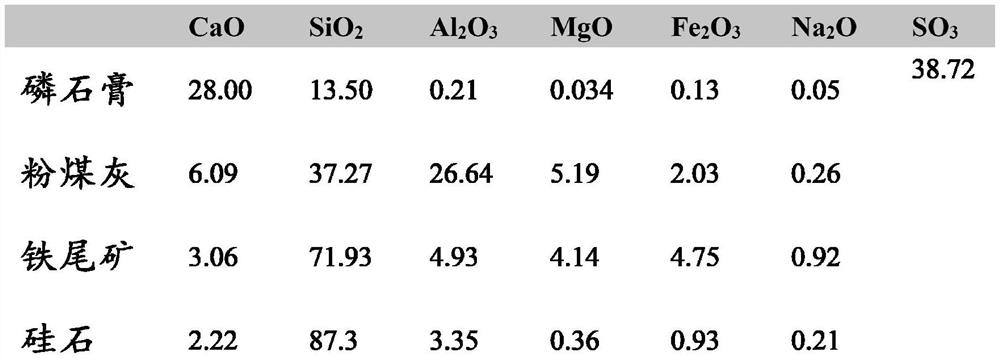

[0068] The composition of raw materials used in this example and the following examples is shown in Table 1.

[0069] Raw material composition (mass fraction %) used in the embodiment of table 1

[0070]

[0071] 100 mass parts of phosphogypsum, 18.5 mass parts of fly ash, 8 mass parts of iron tailings and 10 mass parts of silica are crushed through a 40-mesh sieve, according to the moles of sulfur (S) in carbon (C) and phosphogypsum When the ratio is 0.8, 7.2 parts by mass of coke (with a fixed carbon content of 63.62%) is added, and the acidity index MK=1.32 and pH=4.40 of the batching meet the batching requirements of slag rock wool. All raw materials are mixed evenly and added with binder to make rod-shaped profiles, which are sent to a high-temperature reaction furnace for reduction, roasting and melting in sequence; the temperature of the reduction layer is controlled at 850°C, the average residence time of materials is 10.0 minutes, and the temperature of the roastin...

Embodiment 2

[0073] The phosphogypsum of 100 mass parts, the fly ash of 22.5 mass parts, the iron tailings of 25 mass parts are pulverized and crossed 40 mesh sieves, according to the molar ratio of sulfur (S) in charcoal (C) and phosphogypsum, add coke ( The fixed carbon content is 65.1%) and 8.0 parts by mass, the acidity index MK=1.46 and pH=4.29 of the batching, which meet the batching requirements of slag rock wool. All raw materials are mixed evenly and added with binder to make rod-shaped profiles, which are sent to a high-temperature reaction furnace for reduction, roasting, oxidation and melting in sequence; among them: the temperature of the reduction layer is controlled at 830°C, the average residence time of materials is 15.0 minutes, and the temperature of the roasting layer is 1200°C, the average residence time of the material is 10.0 minutes, the temperature of the molten layer is 1400°C, the average residence time of the material is 6.0 minutes, the molten slag is generated ...

Embodiment 3

[0075] The phosphogypsum of 100 mass parts, the fly ash of 17 mass parts, the iron tailings of 10 mass parts and the silica of 15 mass parts are pulverized through 40 mesh sieves, according to the mole of sulfur (S) in carbon (C) and phosphogypsum When the ratio is 0.85, 7.2 parts by mass of coke (68.21% of fixed carbon content) is added, and the acidity index MK=1.47 and pH=4.15 of the batching meet the batching requirements of slag rock wool. Mix all raw materials evenly and add binder to make a rod-shaped profile, send it into a high-temperature reaction furnace, and perform reduction, roasting and melting in sequence; among them: the temperature of the reduction layer is controlled at 780°C, the average residence time of the material is 18.0 minutes, and the temperature of the roasting layer is 1250 °C, the average residence time of the material is 4.0 minutes, the temperature of the molten layer is 1550 °C, the average residence time of the material is 3.0 minutes, the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com