Recycling process of coal gas waste heat

A waste heat recovery and coal gas technology, applied in the field of heat exchange, can solve the problems of increasing the cost of coal gas and its products, low utilization value, etc., and achieve the effect of reducing the cost of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

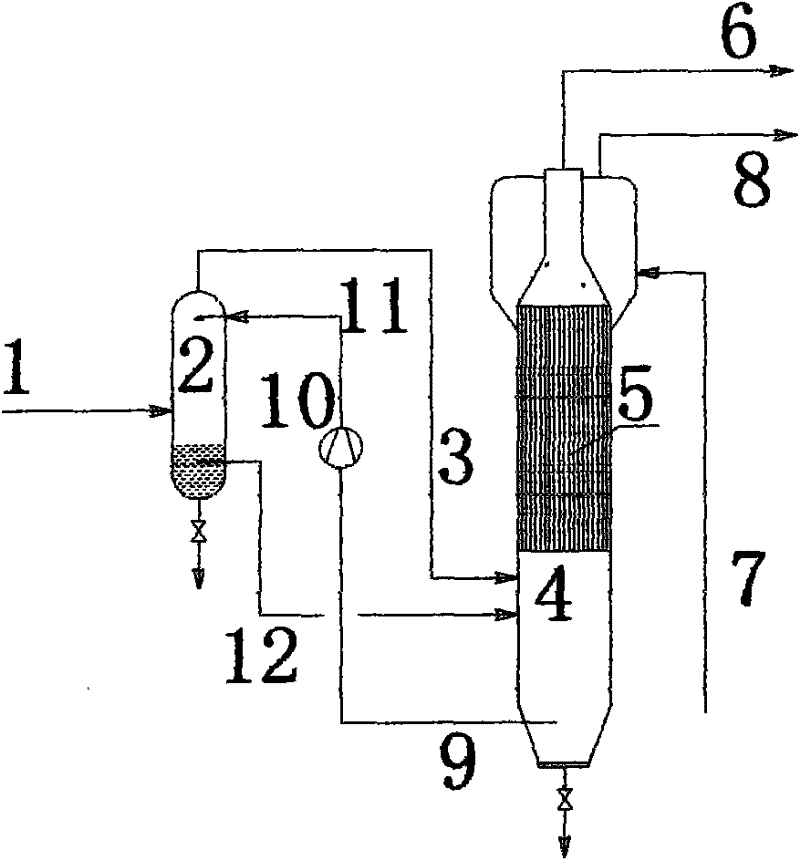

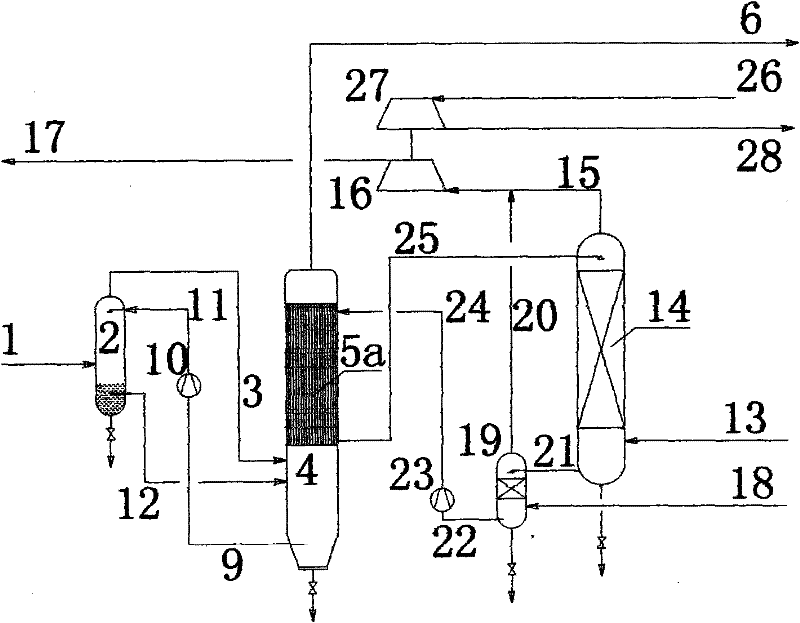

Method used

Image

Examples

Embodiment Construction

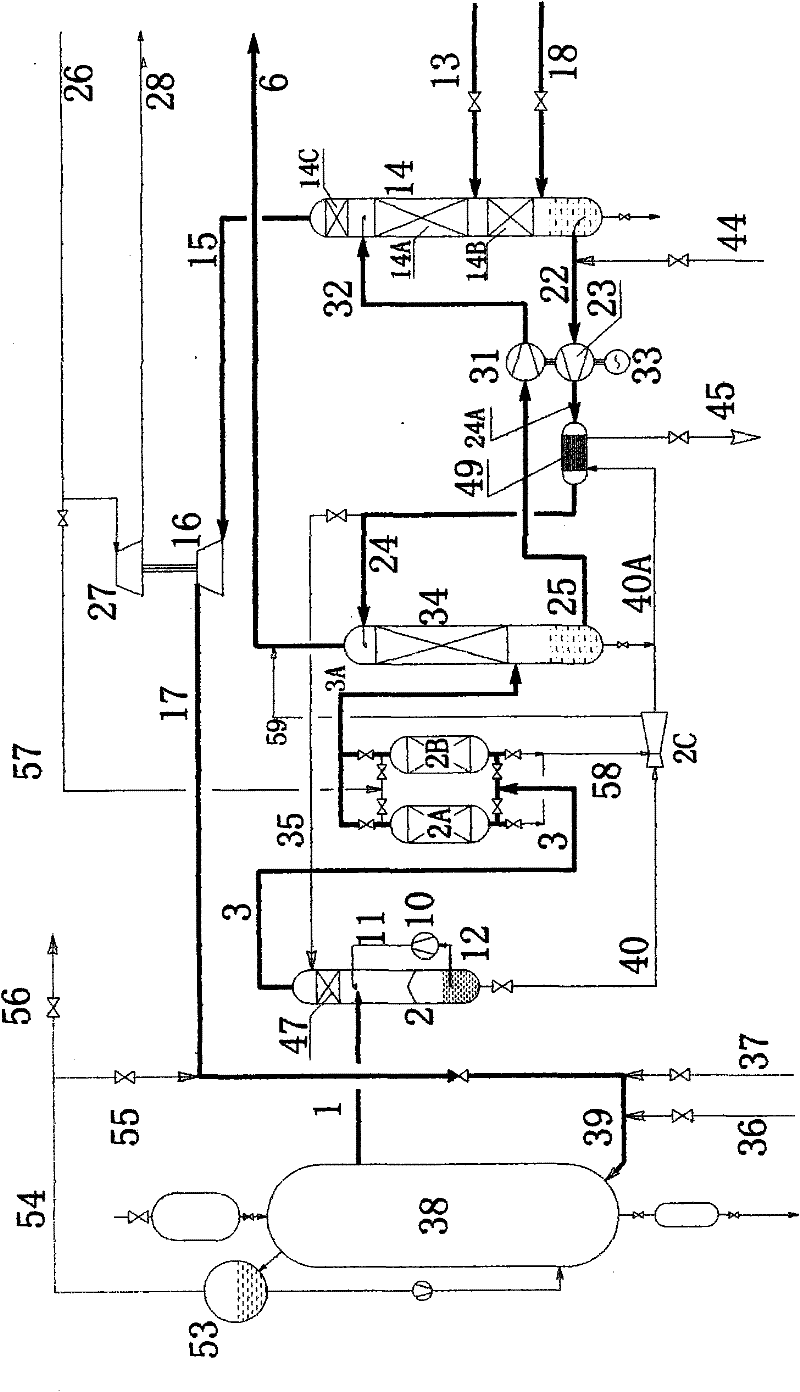

[0099] In the following, 645t / h of lignite raw material with a low calorific value of 13.44MJ / kg, a high water content of 40%, and an ash melting point of 1200°C is used, using a crushed coal moving bed pressurized gasification process, with a steam-to-oxygen ratio of 6, CO 2 / O 2=1, the total steam-oxygen ratio is 7, and the engineering capacity of 4,000,000 cubic meters of natural gas per day is taken as an example to illustrate the main parameters of the concrete implementation of applying the present invention to reclaim coal gas waste heat:

[0100] Total amount of wet gas: 1.42 million Nm 3 / h; temperature 230°C; water vapor content 53%; pressure 3.0MPa.

[0101] Total oxygen: 83000Nm 3 / h; pressure 1.6MPa.

[0102] CO 2 Total: 83000Nm 3 / h; pressure 1.6MPa.

[0103] Static equipment: 1 set of high-pressure mass transfer and heat transfer equipment;

[0104] 1 set of low-pressure mass transfer and heat transfer equipment.

[0105] A set of temperature swing adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com