Tower top dust recovery device for urea granulation tower and recovery method for dust on top of urea granulation tower

A urea granulation tower and dust recovery technology, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of low energy utilization rate, surrounding environmental pollution, and low dust removal efficiency, so as to facilitate absorption, The effect of reducing the carrying load and increasing the diversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

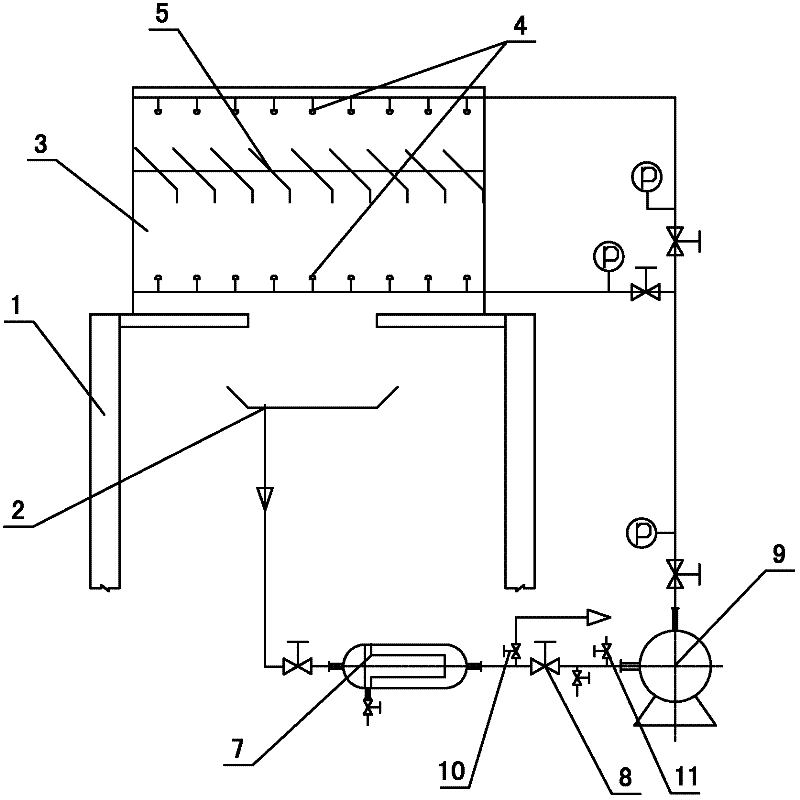

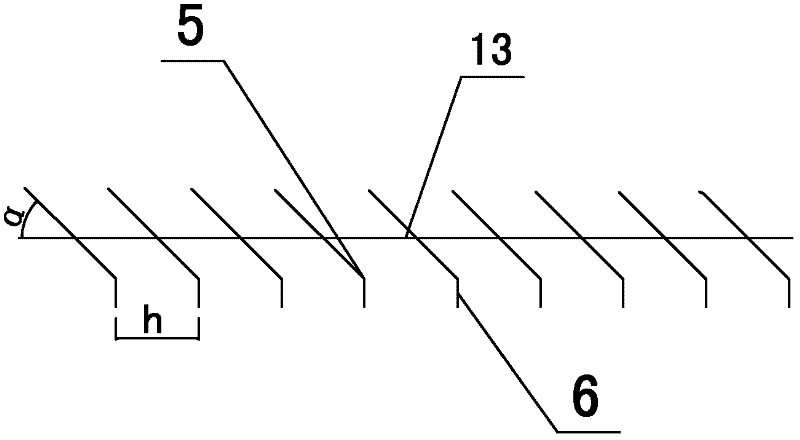

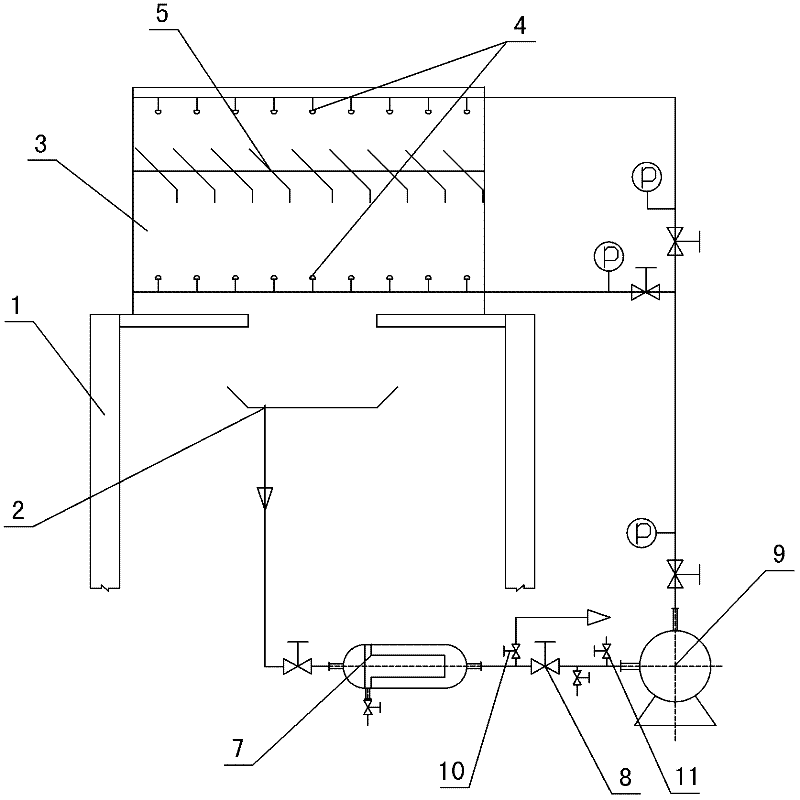

[0017] A urea prilling tower top dust recovery device provided in this embodiment has a structure such as figure 1 As shown, it includes a prilling tower tower body 1 and a receiving tray 2 arranged in the tower body; a cylindrical dust recovery chamber 3 is installed on the top of the tower body, and a middle hot gas chamber is formed at the top of the tower; the diameter of the dust recovery chamber is larger than The diameter of the air outlet at the top of the tower is provided at the upper and lower ends of the dust recovery chamber with a sprinkler 4 composed of a number of spray nozzles evenly distributed, and the direction of the nozzles is relatively arranged; between the sprinklers at both ends, an inclined Filler vacuum device 5 composed of partitions, the inclined direction of the inclined partitions is the same, 6 folded edges at the lower end of the inclined partitions, the folded direction is perpendicular to the horizontal plane, and the inclined partitions are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com