Reduction method of lead-rich slag

A technology of enriching lead slag and reducing agent, which is applied in the field of metal smelting to reduce costs and pollution and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

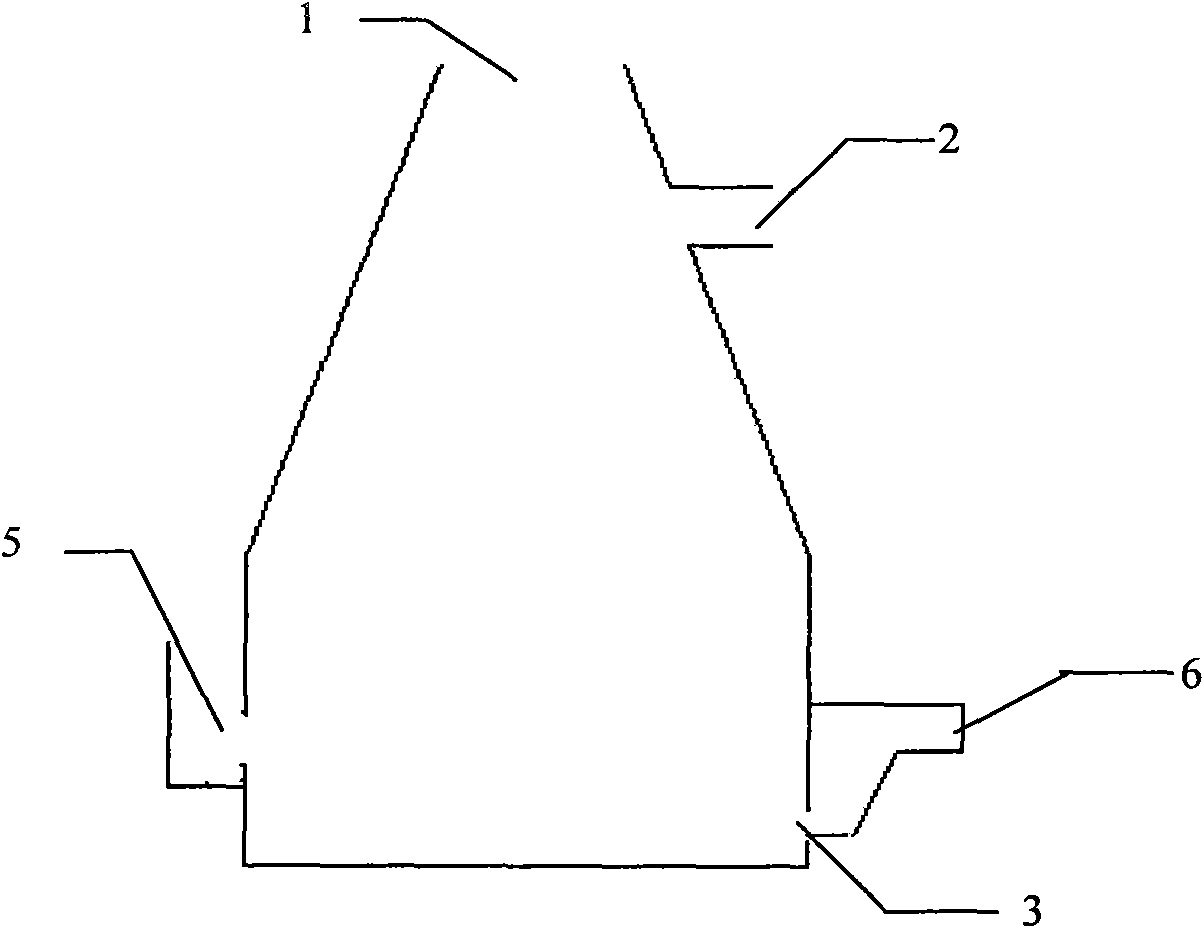

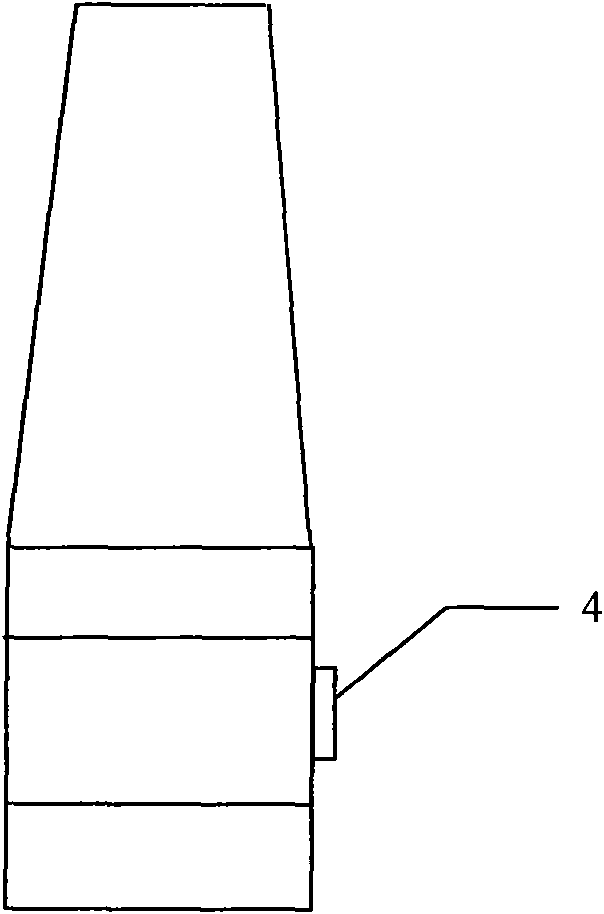

[0008] as attached figure 1 The lead-rich slag shown in the figure enters the furnace through the slag inlet 5, and the powdered coal or coke particles are added from the furnace upper port 1. The side blowing device 4 is used to blow in coalbed methane or natural gas to provide supplementary heat, and the oxygen-enriched air is assisted to raise the temperature of the slag. Above 1100°C, use nitrogen to stir the melt to make the upper reducing agent fully react with the slag, and use the exothermic heat of the reduction reaction to stabilize the temperature of the reaction melt region at 1200-1250°C, which can effectively promote the smooth progress of the reaction. The mixed siphon method of slag and lead is adopted to put it into the front bed 6 from the siphon outlet 3, and the lead and slag are separated in the front bed 6 after static clarification. In order to make full use of the heat of the flue gas and ensure the safety of the flue gas system, the 2. After that, a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com