A process of using blast furnace titanium slag to absorb and regenerate waste lubricating oil

A technology of blast furnace titanium slag and waste lubricating oil, applied in the direction of lubricating compositions, etc., can solve the problems that titanium resources cannot be fully utilized and recycled, and the added value is low, and achieve the realization of high value-added utilization, great significance, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

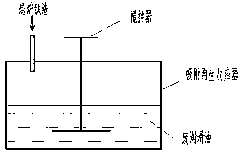

Image

Examples

no. 1 example

[0029] 1) After the blast furnace titanium slag is crushed, ground and screened, the blast furnace titanium slag with a particle size of 75 microns is obtained, which is added to an adsorption regeneration reactor equipped with waste lubricating oil, at a reaction temperature of 80°C, and stirred The adsorption regeneration reaction of the waste lubricating oil is carried out under the agitation of the device. After the reaction is completed, the blast furnace titanium slag is filtered to obtain the regenerated lubricating oil. Wherein, the stirring speed of the agitator is 800 rpm, and the reaction time of the adsorption regeneration reaction is 180 minutes;

[0030] 2) In the above step 1), the blast furnace titanium slag added to the adsorption regeneration reactor equipped with waste lubricating oil, its TiO 2 The content of is 20% (mass percentage), and its addition is 20% of waste lubricating oil quality simultaneously;

[0031] 3) In above-mentioned steps 1), the mass ...

no. 2 example

[0034] 1) After the blast furnace titanium slag is crushed, ground and sieved, the blast furnace titanium slag with a particle size of 95 microns is obtained, which is added to an adsorption regeneration reactor equipped with waste lubricating oil, at a reaction temperature of 100°C, and stirred The adsorption regeneration reaction of the waste lubricating oil is carried out under the agitation of the device. After the reaction is completed, the blast furnace titanium slag is filtered to obtain the regenerated lubricating oil. Wherein, the stirring speed of the agitator is 900 rpm, and the reaction time of the adsorption regeneration reaction is 200 minutes;

[0035] 2) In the above step 1), the blast furnace titanium slag added to the adsorption regeneration reactor equipped with waste lubricating oil, its TiO 2 The content of is 22% (mass percentage), and its addition is 23% of waste lubricating oil quality simultaneously;

[0036] 3) In above-mentioned steps 1), the mass p...

no. 3 example

[0039] 1) After the blast furnace titanium slag is crushed, ground and screened, the blast furnace titanium slag with a particle size of 106 microns is obtained, which is added to an adsorption regeneration reactor equipped with waste lubricating oil, at a reaction temperature of 120°C, and stirred The adsorption regeneration reaction of the waste lubricating oil is carried out under the agitation of the device. After the reaction is completed, the blast furnace titanium slag is filtered to obtain the regenerated lubricating oil. Wherein, the stirring speed of the agitator is 1000 rpm, and the reaction time of the adsorption regeneration reaction is 240 minutes;

[0040] 2) In the above step 1), the blast furnace titanium slag added to the adsorption regeneration reactor equipped with waste lubricating oil, its TiO 2 The content of is 25% (mass percentage), and its addition is 25% of waste lubricating oil quality simultaneously;

[0041] 3) In above-mentioned steps 1), the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com