High-aperture-ratio biomass-based rigid polyurethane foam and preparation method thereof

A technology of rigid polyurethane and polyurethane foam, applied in botanical equipment and methods, planting substrates, culture media, etc., can solve the problem of poor fluidity of the all-water foaming system, increased production costs of isocyanates, and reduced foam dimensional stability, etc. problems, to achieve high value-added utilization, high molding efficiency, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

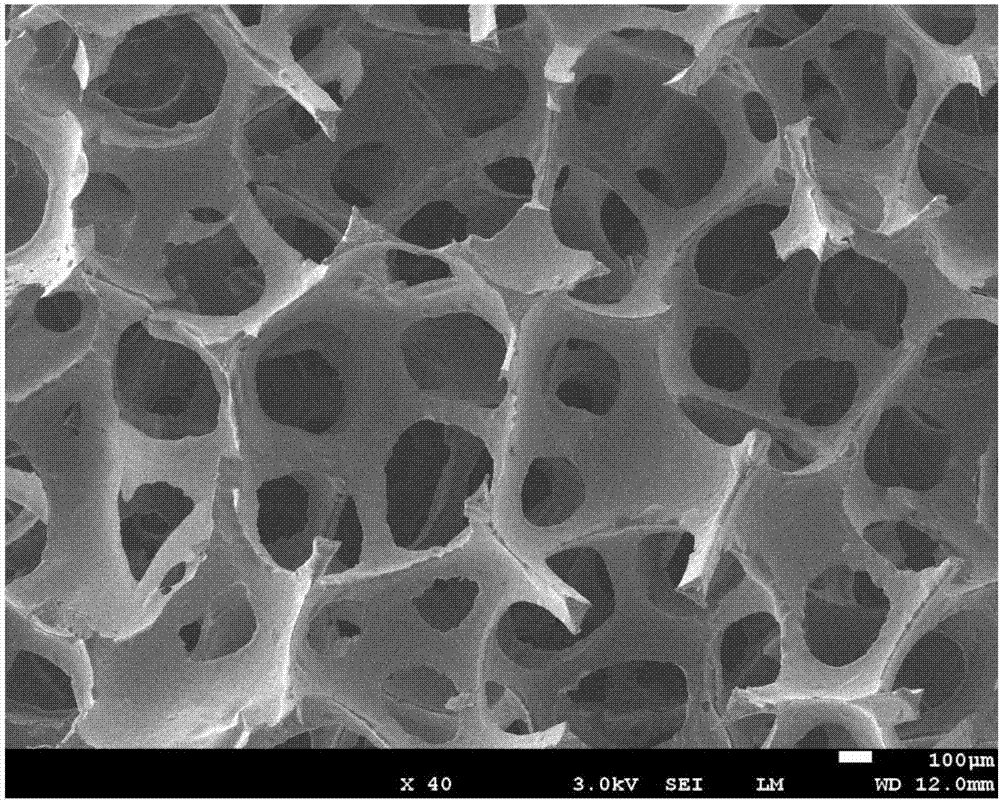

[0047]Embodiment 1: A kind of high opening rate biomass-based rigid polyurethane foam and preparation method thereof

[0048] The proportion of each component is as follows:

[0049] Component A: bio-based polyol mixture, 100 parts; 1.5 parts of water; 0.5 parts of petroleum ether (petroleum ether with a boiling range of 30-60°C and 60-90°C each accounts for 1 / 2 of the total mass of petroleum ether); polyurethane catalyst 1 part of A-33; 0.4 parts of organotin catalyst T-9; 1.5 parts of silicone oil L-580.

[0050] The preparation method of the bio-based polyol mixture is as follows: in a 500mL four-neck flask equipped with a stirrer, a thermocouple, and a condensing reflux tube, add 30g of peanut shell powder, 240g of polyethylene glycol, and 60g of glycerol, and put Stir evenly in an oil bath that has been preheated to 150°C, slowly add 5.1g of sulfuric acid (mass fraction: 98%) dropwise, after completion, keep the reaction at 150°C for 2 hours, stop stirring and heating, p...

Embodiment 2

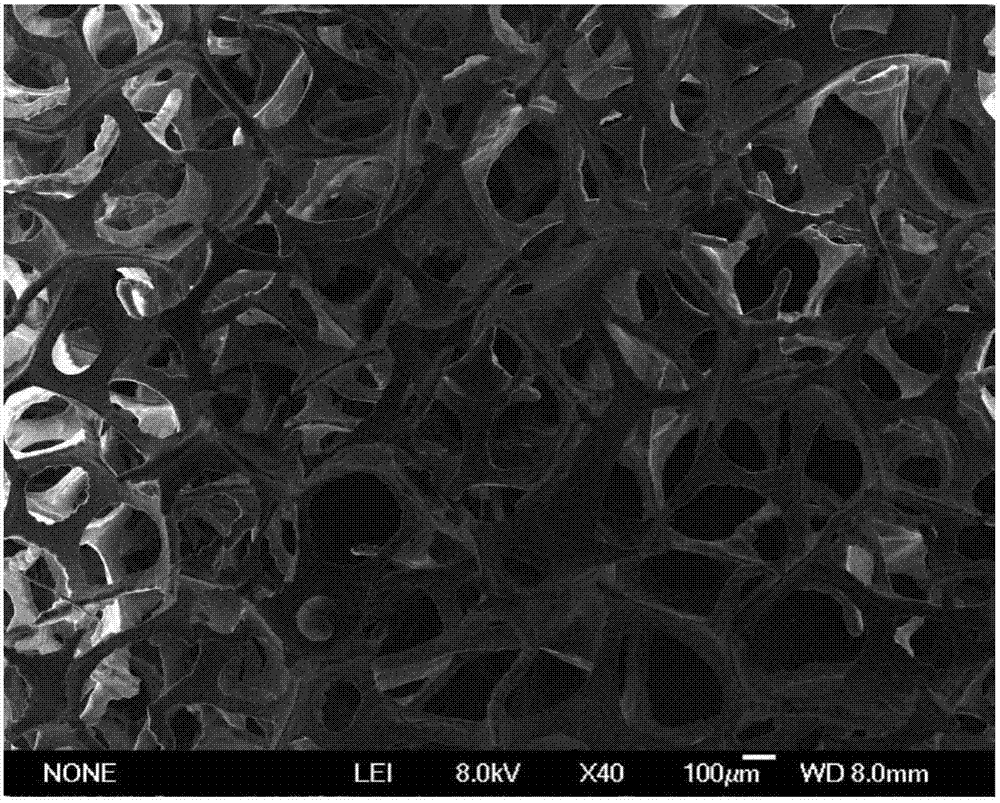

[0059] Embodiment 2: A kind of high opening rate biomass-based rigid polyurethane foam and its preparation method

[0060] The proportion of each component is as follows:

[0061] Component A: 100 parts of bio-based polyol mixture; 2.5 parts of water; 3 parts of petroleum ether (petroleum ether with a boiling range of 30-60°C and 60-90°C each accounts for 1 / 2 of the total mass of petroleum ether); polyurethane catalyst A -33 0.75 parts; organotin catalyst T-9 0.3 parts; silicone oil L-580 2.5 parts.

[0062] The preparation method of the bio-based polyol mixture is as follows: in a 500mL four-neck flask equipped with a stirrer, a thermocouple, and a condensing reflux tube, add 30g of peanut shell powder, 240g of polyethylene glycol, and 60g of glycerol, and put Stir evenly in an oil bath that has been preheated to 150°C, slowly add 5.1g of sulfuric acid (mass fraction: 98%) dropwise, after completion, keep the reaction at 150°C for 2 hours, stop stirring and heating, pour int...

Embodiment 3

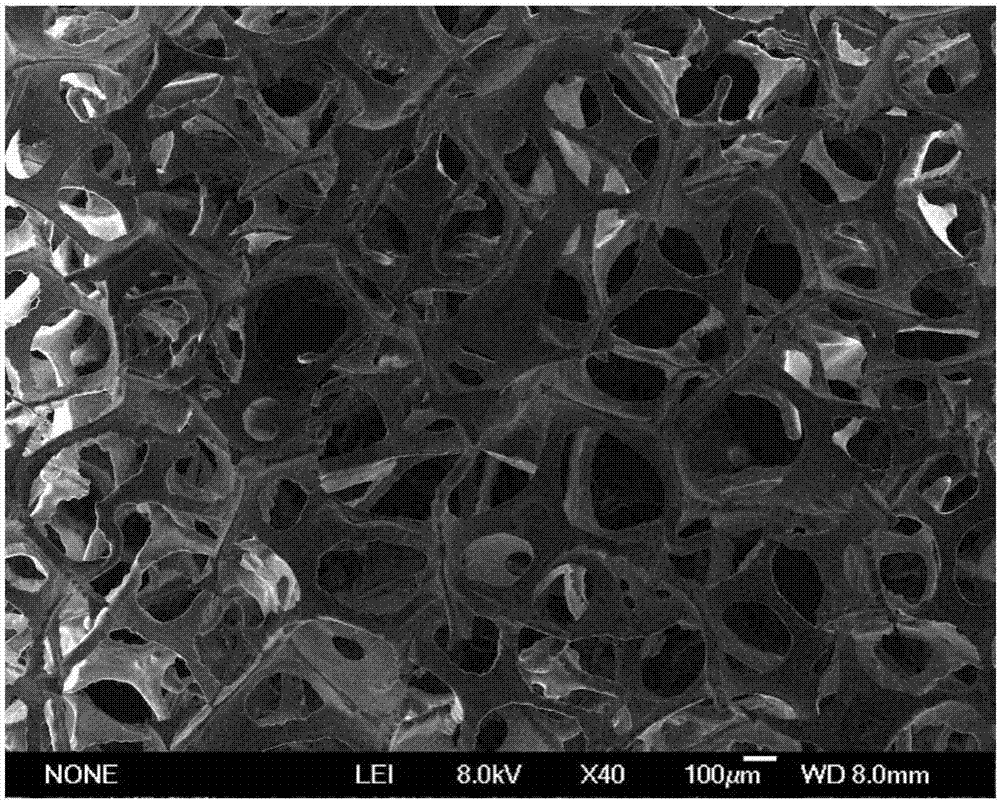

[0071] Embodiment 3: A kind of bio-based rigid polyurethane foam with high open cell ratio and its preparation method

[0072] The proportion of each component is as follows:

[0073] Component A: 100 parts of biomass-based polyol mixture; 2 parts of water; 1.5 parts of petroleum ether (petroleum ether with a boiling range of 30-60°C and 60-90°C each accounts for 1 / 2 of the total mass of petroleum ether); polyurethane catalyst 1 part of A-33; 0.3 parts of organotin catalyst T-9; 2.5 parts of silicone oil L-580.

[0074] The preparation method of the bio-based polyol mixture is as follows: in a 500mL four-neck flask equipped with a stirrer, a thermocouple, and a condensing reflux tube, add 30g of peanut shell powder, 240g of polyethylene glycol, and 60g of glycerol, and put Stir evenly in an oil bath that has been preheated to 150°C, slowly add 5.1g of sulfuric acid (mass fraction: 98%) dropwise, after completion, keep the reaction at 150°C for 2 hours, stop stirring and heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com