Method for preparing dopamine and derivative thereof by utilizing agricultural and forestry wastes and special equipment thereof

A technology of agricultural and forestry waste and dopamine, which is applied in the preparation of organic compounds, preparation of amino hydroxyl compounds, chemical instruments and methods, etc., can solve the problems of unsatisfactory utilization, difficulty in concentration, and low added value of products, and achieve high added value The effect of high value utilization, purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

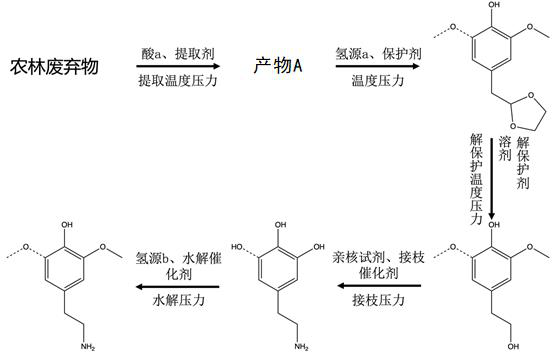

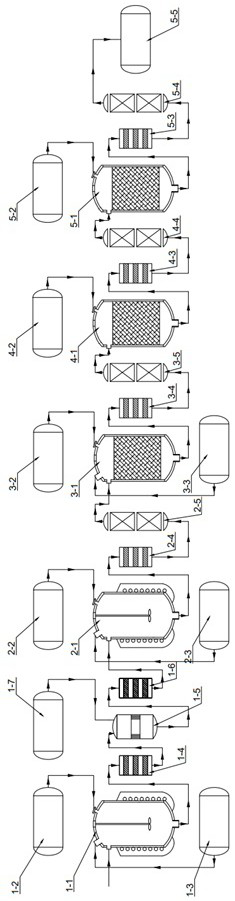

Method used

Image

Examples

Embodiment 1

[0048] Take 50g of sawdust, add 28mL of 37 wt% hydrochloric acid and 400mL of methanol, react at 70°C and normal pressure for 72h, filter the reaction solution, evaporate to remove methanol, add ice deionized water, and dry the precipitate to obtain Product A;

[0049] Add 12mL of 70wt% sulfuric acid and 6mL of ethylene glycol to product A, acidolysis reaction at 150°C with an initial pressure of 1MPa nitrogen (as a protective gas) for 2h, filter the reaction solution, and evaporate to extract 3.31g of product B , ethylene glycol is used to protect the aldehyde group during the reaction;

[0050] Add 6wt% sulfuric acid and 0.1 g of Ru / C deprotection catalyst to product B, react for 1 h at 120°C and fill with nitrogen gas (as a protective gas) with an initial pressure of 0.1 MPa, filter the reaction solution, and evaporate to extract product C 2.99g;

[0051] Dissolve product C in p-xylene solvent, add 0.1 g of Ru / hydroxyapatite graft catalyst and ammonia gas with an initial ...

Embodiment 2

[0054] Take 50g of straw, add 30 mL of 70 wt% hydrochloric acid and 500 mL of ethanol, react at 78 °C and normal pressure for 48 hours, filter the reaction solution, evaporate to remove methanol, add ice deionized water, and dry the precipitate Product A is obtained;

[0055] Add 12mL of 70wt% sulfuric acid and 6mL of ethylene glycol to product A, react at 150°C and 1MPa initial pressure of nitrogen for 2h, filter the reaction solution, and evaporate to extract 4.46g of product B;

[0056] Add 6wt% sulfuric acid and 0.1 g of Ru / C deprotection catalyst to product B, react for 1 h at 120 ° C, initial pressure of 0.1 MPa nitrogen, filter the reaction solution, and evaporate to extract 3.97 g of product C;

[0057] Dissolve product C in p-xylene solvent, add 0.1g of Ru / hydroxyapatite graft catalyst and ammonia gas with initial pressure of 0.2MPa, and nitrogen gas with initial pressure of 0.8MPa to adjust the pressure, at 200°C After reacting for 8h, the reaction solution was filt...

Embodiment 3

[0060] Take 50g of sawdust, add 28mL of 37wt% hydrochloric acid and 400mL of methanol, react at 70°C and normal pressure for 72h, filter the reaction solution, evaporate to remove methanol, add iced deionized water, and dry the precipitate to obtain the product A;

[0061] Take 5 g of product A, add 1 mL of trifluoromethanesulfonic acid and 6 mL of ethanedithiol, react for 3 hours at 120 °C under normal pressure, filter the reaction solution, and evaporate to extract 2.45 g of product B;

[0062] Add 12wt% sulfuric acid and Ru / C to product B 3 N 4 Deprotection catalyst 0.1g, reacted at 120°C and initial pressure of 0.1MPa nitrogen for 1h, filtered the reaction solution, and evaporated to extract 2.23g of product C;

[0063] The product C was dissolved in p-xylene solvent, CH 2 =CH 2 Nucleophile 2mL, Ru / CeO 2 Graft catalyst 0.1g, react at 200°C for 8h, filter the reaction solution, and evaporate to extract 1.81g of product D;

[0064] Add water 10mL, Nb 2 o 5 Hydrolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com