Treatment method of gold tailings

A treatment method and technology of gold tailings, applied in the field of comprehensive utilization of solid waste resources, can solve problems such as difficulties in the comprehensive utilization of gold tailings, complex recycling process, etc., and achieve industrial application, good treatment effect, and high value-added utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The present embodiment provides a method for treating gold tailings, and the gold tailings to be treated are gold tailings in the Jiaolai area of Shandong, and the components are shown in Table 1;

[0061] Table 1 Composition of gold tailings in Jiaolai area, Shandong, wt%

[0062] Tailings Field SiO 2

Al 2 O 3

CaO MgO Fe 2 O 3

TiO 2

K 2 O

Na 2 O

Au(g / t) Shandong Jiaolai 69.9 15.9 1.96 0.49 1.02 0.24 5.43 4.19 0.2~0.6

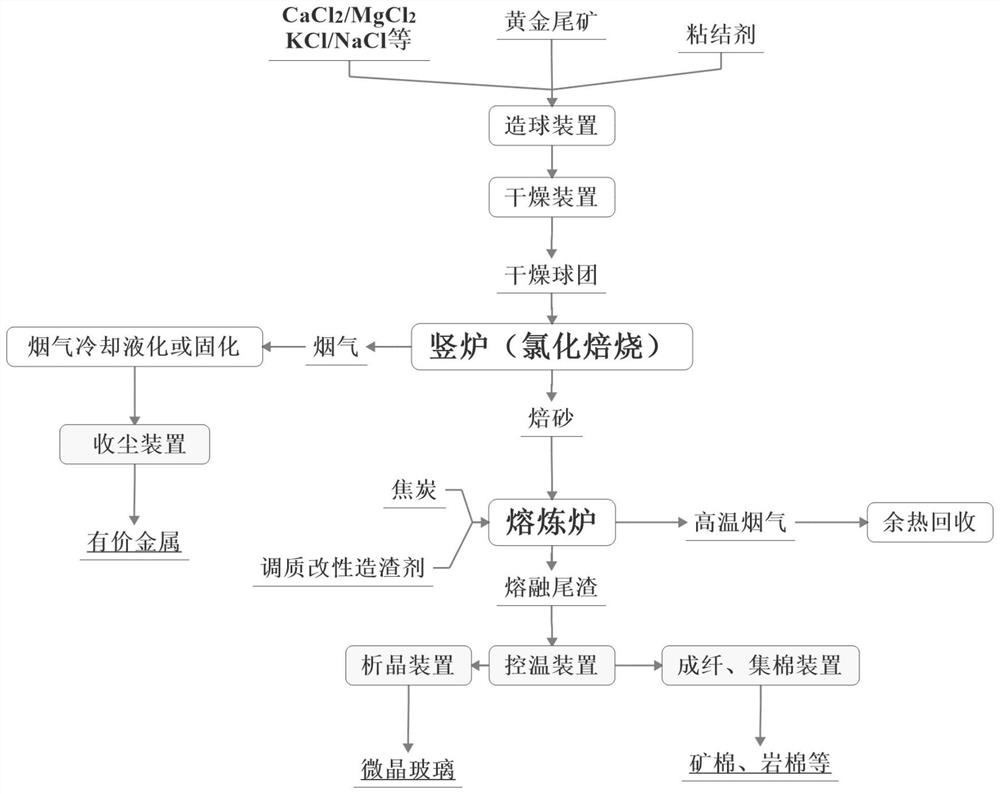

[0063] like figure 1 As shown, the specific processing method includes the following steps:

[0064] Step (1): with the gold tailings to be treated and the chlorinating agent CaCl 2 Mix evenly at a mass ratio of 10:1; add binder water to the mixed material, roll forming, control water content ≈ 20%, ball diameter 10±2mm, take the pellet and place it at 250 ℃ to dry for 2 hours; dry ball The moisture content of pellets is less than 0.5%, and the strength of dry pellets is 60-70...

Embodiment 2

[0073] The present embodiment provides a method for treating gold tailings, which differs from Embodiment 1 only in that steps (2) and (3) are different, as follows:

[0074] Step (2): the calcine and the waste limestone (the mass fraction of CaO in the waste limestone is 95%) are uniformly mixed at a mass ratio of 2:1, and the acidity coefficient of the mixture is 1.71; Steel coke; smelting at 1000-1600 °C to obtain high temperature flue gas and molten tailings;

[0075] Step (3): Utilize described molten tailings to prepare fiber cotton, specifically as follows:

[0076] The molten tailings flow out from the slag outlet, and are spun into fibers by a three-roll centrifuge. process to obtain slag wool board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com