Preparation method of three-dimensional boron-nitrogen co-doped layered carbon for water system high-voltage supercapacitor

A supercapacitor, high-voltage technology, used in carbon preparation/purification, hybrid capacitor electrodes, etc., can solve the problems of difficult to improve SC energy density, low decomposition voltage, etc., to achieve high energy density, wide voltage window, high ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

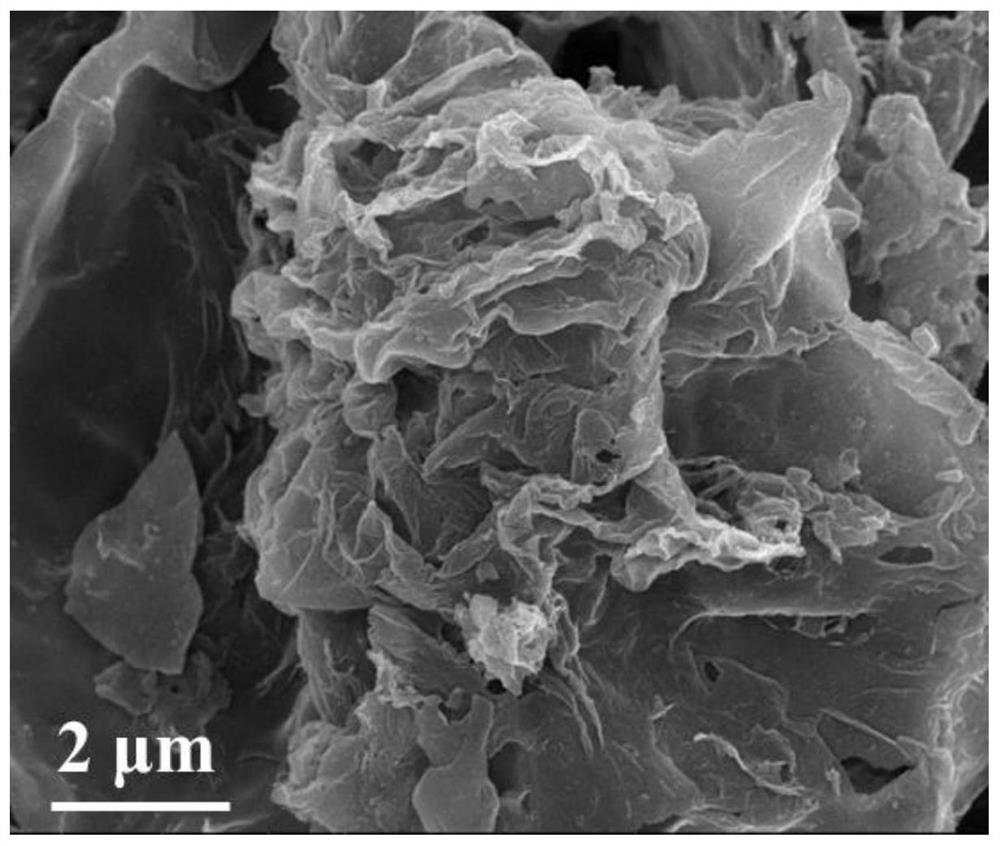

[0024] Example 1: Three-dimensional boron-nitrogen co-doped layered carbon BNLC 1 The specific preparation process is as follows:

[0025] (1) Pretreatment of reactant: Weigh 4g of potassium borate and 1g of 2-methylimidazole solids and dissolve them in deionized water, slowly add 4g of powdered sweet-scented osmanthus, heat at 60°C for 8 hours, and then heat until the water in the mixture is relatively low. When it is small, it is transferred to the refrigerator to freeze for 24 hours to obtain the reactant.

[0026] (2) Preparation of three-dimensional boron-nitrogen co-doped layered carbon: put the reactant obtained in step (1) into a corundum boat, then place the above-mentioned corundum boat in a tube furnace, and pass in argon gas to exhaust the tube type After the air in the furnace is removed, continue to use argon as the protective gas, heat up to 180°C at a heating rate of 2°C / min, and keep the temperature constant for 60 minutes; then heat to 600°C at a heating rat...

Embodiment 2

[0027] Embodiment 2: three-dimensional boron nitrogen co-doped layered carbon BNLC 2 The specific preparation process is as follows:

[0028] (1) Pretreatment of reactants: implement according to the same method as step (1) in Example 1, the difference is that the quality of boric acid is 8g;

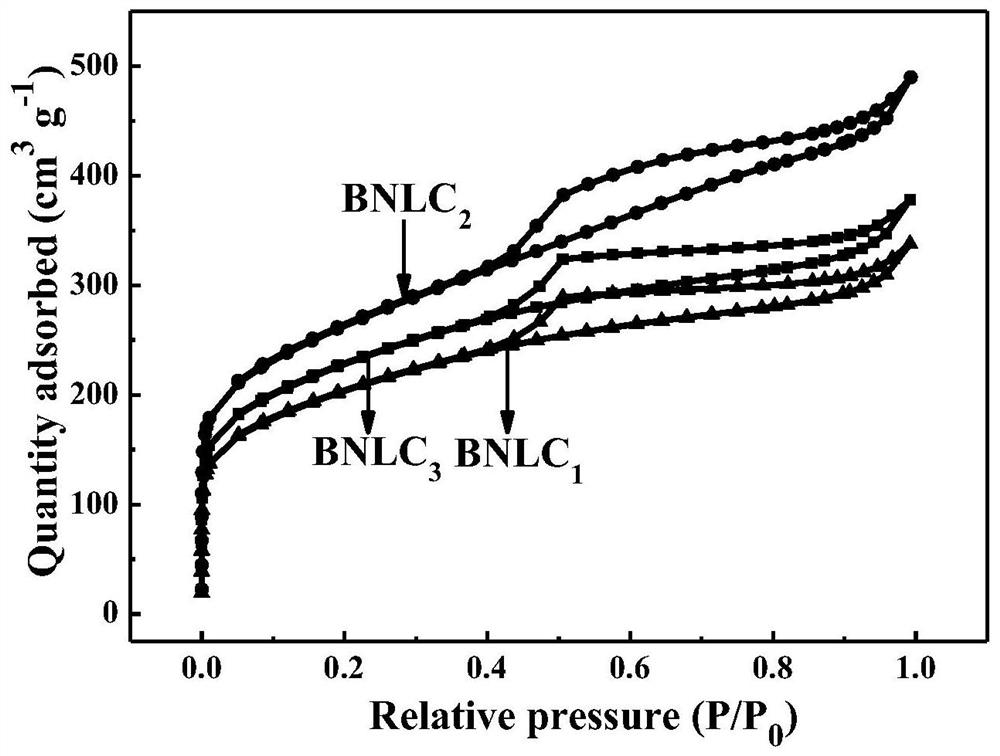

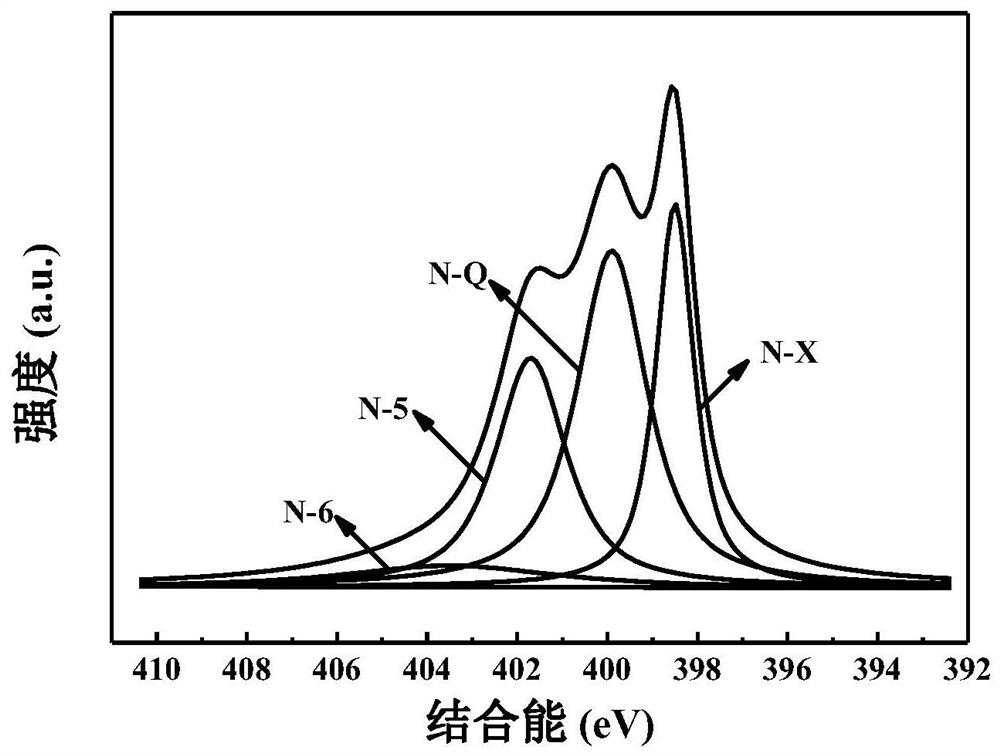

[0029] (2) Preparation of three-dimensional boron-nitrogen co-doped layered carbon: the same method as step (2) in Example 1 was implemented. The resulting three-dimensional boron-nitrogen co-doped layered carbon is denoted as BNLC 2 , XPS test results (such as Figure 2-4 Shown) show that its boron content is 2.01%, nitrogen content is 5.29%. BNLC 2 When used as a supercapacitor electrode material, at 3mol / L Zn(CF 3 SO 3 ) 2 In the electrolyte, when the current density is 0.05A / g, BNLC 2 The capacity is up to 315.3F / g, the energy density is up to 43.8Wh / kg; when the current density is 40A / g, BNLC 2 The capacity is up to 241.1F / g.

Embodiment 3

[0030] Embodiment 3: three-dimensional boron nitrogen co-doped layered carbon BNLC 3 The specific preparation process is as follows:

[0031] (1) Pretreatment of reactants: implement according to the same method as step (1) in Example 1. The difference is that the mass of potassium borate is 12g;

[0032] (2) Preparation of three-dimensional boron-nitrogen co-doped layered carbon: the same method as step (2) in Example 1 was implemented. The resulting three-dimensional boron-nitrogen co-doped layered carbon is denoted as BNLC 3 , its boron content is 1.51%, nitrogen content is 3.54%. BNLC 3 When used as a supercapacitor electrode material, at 3mol / L Zn(CF 3 SO 3 ) 2 In the electrolyte, when the current density is 0.1A / g, BNLC 3 The capacity is up to 275.1F / g, the energy density is up to 38.2Wh / kg; when the current density is 20A / g, NPFC 800 The capacity is up to 204.5F / g.

[0033]The three-dimensional boron-nitrogen co-doped layered carbon prepared in Examples 1-3 wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com