Electric cooker

A technology for a rice cooker and a cooker body is applied in the directions of cooking utensils, household utensils, applications, etc., which can solve the problems of inability to obtain, consume power, and consume large amounts of electricity, and achieve the effect of promoting gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

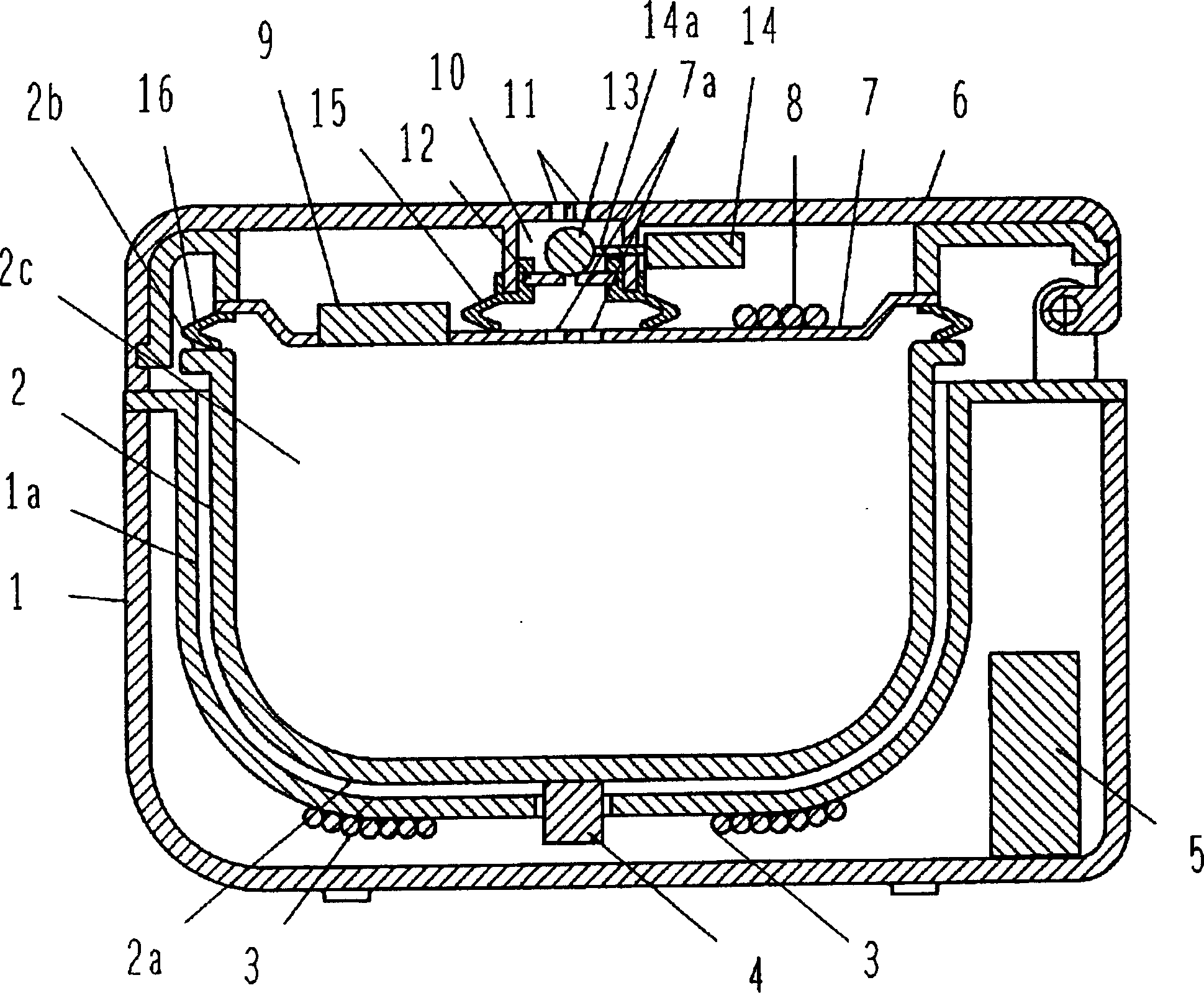

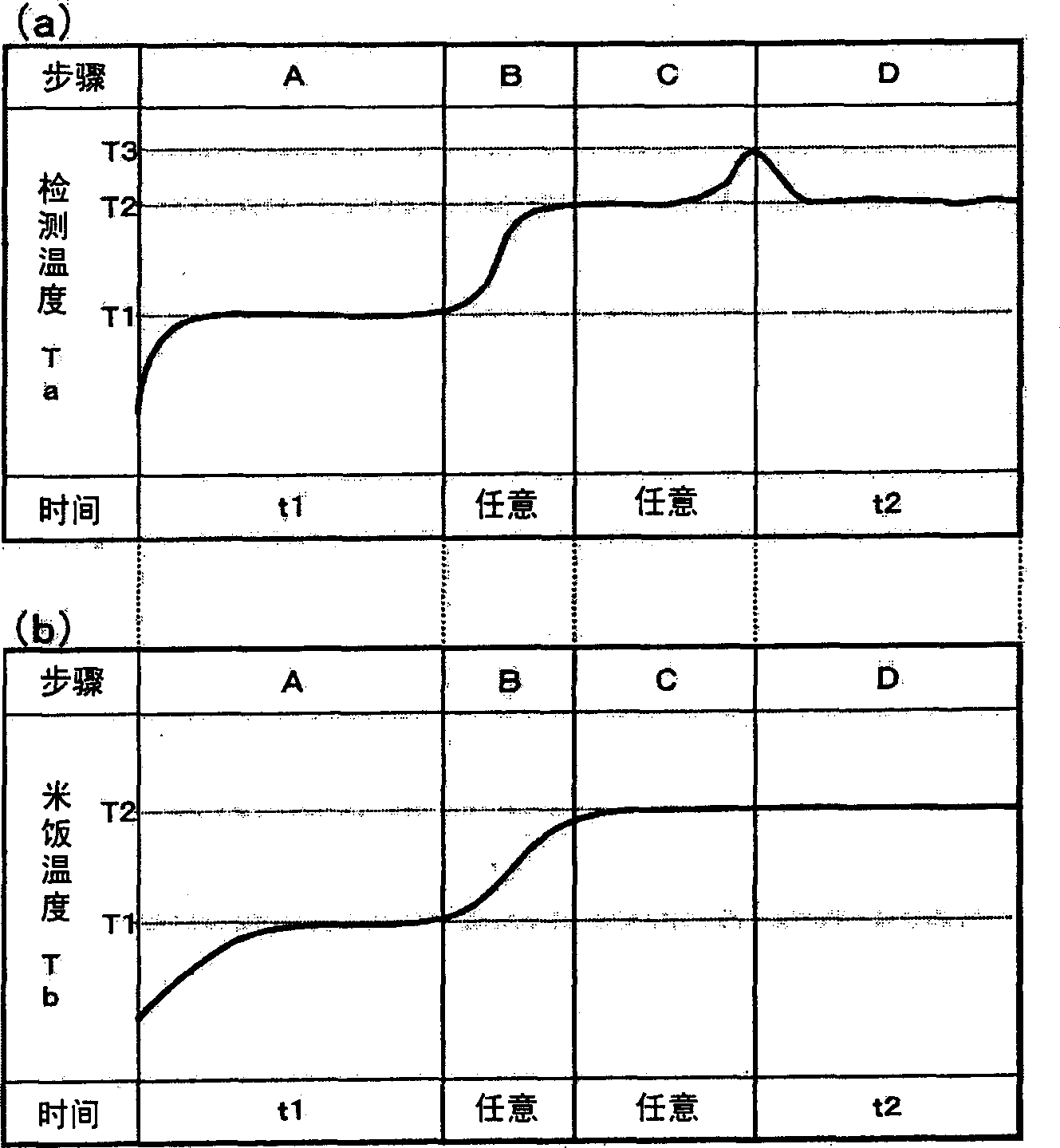

[0029] first pass figure 1 The electric rice cooker in Embodiment 1 of the present invention is described.

[0030] Such as figure 1 As shown in , the body 1 of the electric rice cooker is provided with a bottomed cylindrical pot cavity 1a, into which the pot 2 can be assembled and disassembled. A pot heating coil 3 is provided at the bottom of the pot holding cavity 1a, and the pot heating coil 3 is used as a pot heating device for inductively heating the pot 2. 4 is a pot bottom temperature sensor, which is arranged to withstand the bottom surface 2a of the pot 2. The control device 5 controls the operation of the rice cooker.

[0031] In addition, the lid 6 is supported by a pivot (not shown) in the pivot assembly provided at the rear of the rice cooker body 1, and covers the opening of the pot 2 in a freely openable and closable manner. The pot lid 6 is provided with a heat radiation plate 7 and a lid heater 8 as a lid heating device for heating the heat radiation pl...

Embodiment 2

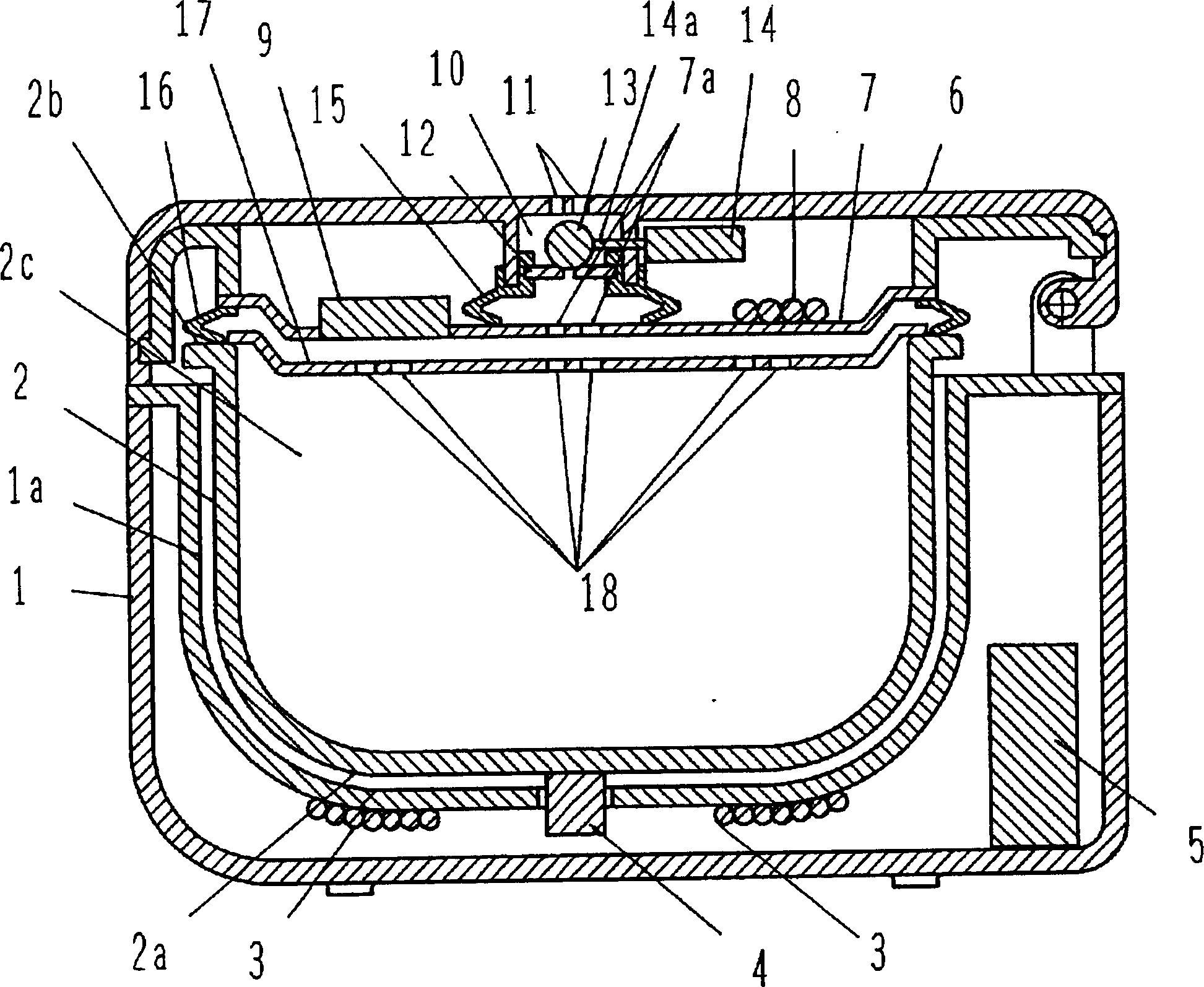

[0046] In this example, if image 3 As shown in , an inner cover 17 is provided between the heat radiation plate 7 and the inner space 2c of the pot 2, and a plurality of inner cover steam ports 18 are provided on this inner cover 17. Other constitutions are the same as in Embodiment 1.

[0047] In the cooking step and the boiling maintenance step, rice juice (rice soup) produced in the cooking process will be attached to the steam heating device 9; A starch film forms on the surface. Such a film acts as a thermal insulation layer of the steam heating device 9 when steam heating is performed in the cooking step, thereby degrading the steam heating performance. In order to improve the steam heating performance, although the method of raising the temperature of the steam heating device 9 in the cooking step can be adopted, if the temperature is too high, the surface layer of the rice will be affected by the radiant heat of the steam heating device 9 in turn. Deterioration occ...

Embodiment 3

[0052] In this example, if Figure 4 A pan side heating means, ie a side coil 25, is provided as shown in . Other constitutions are the same as in Embodiment 1.

[0053] In this embodiment, the side coil 25, which is the side heating device for the pot, heats the side 22d of the pot by induction heating during the cooking, boiling maintaining step and steaming step.

[0054] Because it is heated from the side 22d of the pot, the situation that the radiant heat radiates directly to the rice can be greatly reduced. Therefore, even if the inner cover is not provided, the rice on the upper layer in the pot can be prevented from drying out, and the environment in the pot can be kept at the same time. The temperature was maintained at 130°C. In this way, even if the inner cover is not provided, the situation of uneven cooking in the pot can be improved, thereby providing an electric rice cooker capable of making the cooked rice more delicious.

[0055] In addition, in the steamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com