Cellulose pulp and production method thereof

A technology of cellulose pulp and production method, applied in the field of cellulose pulp, can solve the problems of low production efficiency, slow reaction speed and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

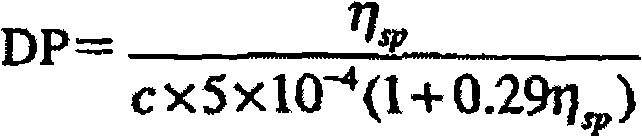

Method used

Image

Examples

Embodiment 1

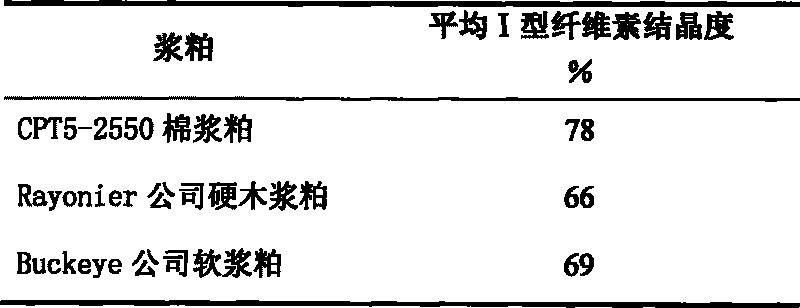

[0077] Select ten kinds of cotton linters of different origins or different maturities, and process each of them into cotton pulp according to the following process and test the crystallinity of the pulp by the above method:

[0078] (1) Material selection (50 kg), open cotton, and dry impurity removal: When selecting materials, select high-quality cotton linters with no impurities and no foreign fibers. Use a cotton opener to tear the cotton linters, and use a trash remover to select and remove impurities;

[0079] (2) Processing cotton linters into cellulose pulp: including material preparation, pre-soaking, cooking, washing, beating, sand removal, concentration, oxidation, bleaching, and sand removal.

[0080] Put the raw materials into a digester, add NaOH with 7% of the absolute dry lint content, use sodium dodecylbenzene sulfonate with 1.2% of the absolute dry lint content, and add hydrogen peroxide with 1.2% absolute dry lint content. Add 0.2% of the absolute dry lint amount ...

Embodiment 2

[0088] (1) Material selection, cotton opening, dry impurity removal: When selecting materials, select high-quality Class II cotton linters with no impurities and no foreign fibers, and their maturity is 69%. Use a cotton opener to tear the cotton linters, and use a trash remover to select and remove impurities;

[0089] (2) Preparation, prepreg, cooking, washing, beating, desanding, concentration, oxidation, bleaching, desanding, steps and processes refer to Example 1.

[0090] (3) Sheet the cellulose slurry.

[0091] After the above-mentioned cellulose pulp is prepared and pulped, the cellulose pulp is cut into a sheet shape.

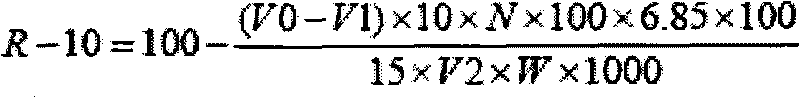

[0092] The slurry concentration is controlled at 1.2-1.3%. Control the pressure of the roller of the net part is 2.5kgf / cm 2 , One squeezing pressure is 3.5kgf / cm 2 、The second pressing pressure is 5.5kgf / cm 2 , So as to ensure the stability of the moisture and density of the pulp before drying. The temperature of the first group of drying cylinders is contr...

example 2

[0094] Table 3 Example 2 Main indexes of preparing cotton pulp

[0095] density:

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com