Recycle method of acetate fiber in waste acetate fiber tow filter rod leftovers

A technology of fiber tow and acetate fiber, which is applied in the field of separation of acetate fiber and paper, can solve the problems of environmental pollution and waste of resources, and achieve the effects of wide application, low production cost and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 4.8g of waste cellulose acetate tow nozzle stick, add it to 30mL ethanol with a volume percentage concentration greater than 95%, soak for 1 hour, centrifuge, vacuum dry and recover 24mL of ethanol, and the recovery rate of ethanol is 80.0%. Then the dried waste cellulose acetate tow nozzle rod is added to 40mL industrial grade or acetone with a concentration of 99% by volume. After the melting is completed, the paper sheet is filtered off, and the filtrate is evaporated to make the solvent content less than 1% of the total weight. Acetone was 35 mL, and the recovery rate was 87.5%, and 3.53 g (calculated as CA) of solid diacetate cellulose was obtained, and the recovery rate was 93.0%.

Embodiment 2

[0030] Weigh 20.0 g of waste cellulose acetate tow tip, add it to 200 mL of ethanol with a concentration greater than 95% by volume, soak for 1 hour, centrifuge and vacuum dry to recover 185 mL of ethanol, and the recovery rate of ethanol is 92.5%. Then the dry waste cellulose acetate tow nozzle rod is added to 180mL industrial grade or acetone with a volume percentage concentration of 99%. After the melting is completed, the paper sheet is filtered off, and the filtrate is evaporated to dryness so that the solvent content is less than 1% of the total weight. 170 mL of acetone, the recovery rate was 94.4%, and 15.1 g (calculated as CA) of solid diacetate fiber was obtained, and the recovery rate was 95.8%.

Embodiment 3

[0032] Weigh 1000.0 g of waste cellulose acetate tow tip, add it to 6500 mL of ethanol with a concentration greater than 95% by volume, soak for 1 hour, and recover 5800 mL of ethanol by centrifugation, with an ethanol recovery rate of 92.5%. Then the dry waste cellulose acetate tow nozzle rod is added to 10000mL industrial grade or acetone with a volume percentage concentration of 99%. After the melting is completed, the paper sheet is filtered off, and the filtrate is evaporated to dryness so that the solvent content is less than 1% of the total weight. Acetone 9560mL, the recovery rate was 95.6%, and 775.0 g (calculated as CA) of solid diacetate fiber was obtained, and the recovery rate was 98.1%.

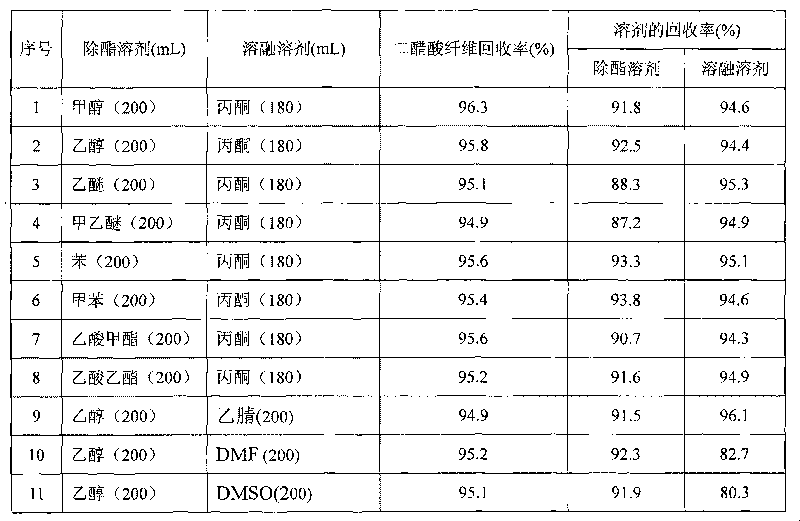

[0033] According to the above basic operation steps, the results of reclaiming diacetate fiber under different conditions are shown in Table 1.

[0034] Table 1 Recovers a list of diacetate fibers under different conditions

[0035]

[0036] Listed in Table 1 above:

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com