Preparation method for holocellulos nano composite film

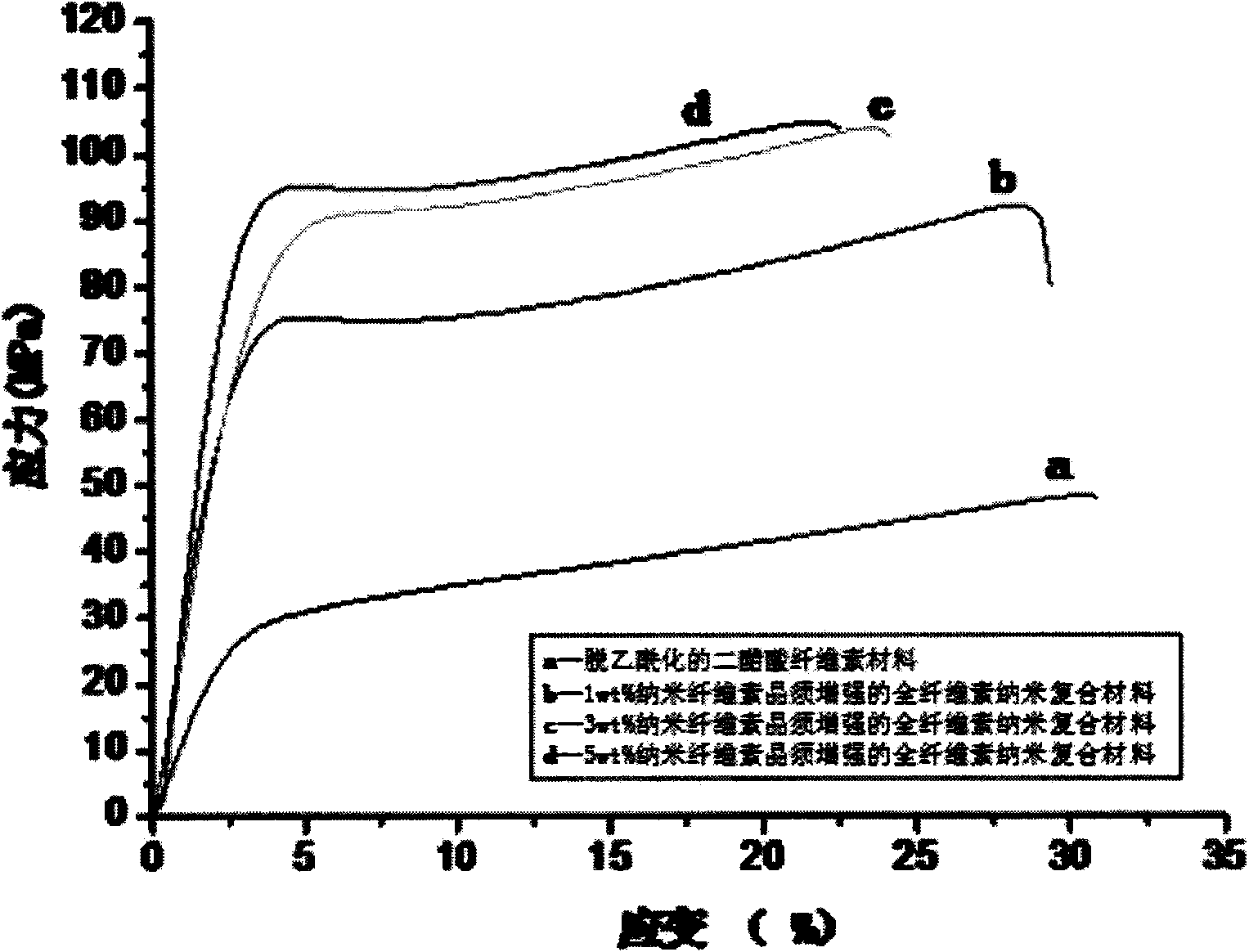

A nano-composite, all-cellulose technology, applied in the field of preparation of all-cellulose nanocomposite films, can solve the problems of expensive solvents, harsh dissolution conditions, difficult to recycle, etc., and achieve good transparency and oxygen barrier properties, excellent physical and mechanical properties. , easy to dissolve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) Preparation of microfibrillated cellulose aqueous suspension

[0014] The cellulose aqueous slurry is first ground with a planetary ball mill, and the added cellulose aqueous slurry accounts for two-thirds of the volume of the vacuum ball mill tank, and is ground at a speed of 600r / min for 20min to obtain a micron-sized cellulose aqueous suspension; The suspension was subjected to high-pressure homogenization treatment, and passed through the high-pressure homogenizer 30 times at a machine pressure of 113 MPa to prepare a microfibrillated cellulose aqueous suspension.

[0015] (2) Conversion of nanocellulose aqueous suspension dispersion medium

[0016] Centrifuge the nanocellulose aqueous suspension (the speed is 4000r / min, experience shows that at this speed, the nanocellulose will settle in the lower layer of the centrifuge tube without causing agglomeration; the dispersion time is 6min), and a part of it is separated and removed. Add water, add acetone, centrif...

Embodiment 2

[0024] (1) Preparation of Nanocellulose Whiskers Suspension

[0025] Fully swell the microcrystalline cellulose powder in deionized water. Under the condition of cold water bath, titrate concentrated sulfuric acid thereinto to mass fraction 64%, stir continuously until there is no obvious agglomeration, then place it in a constant temperature water bath at 45°C and stir for 2h; take a certain amount of deionized water and dilute it and carry out centrifugation (speed 12000r / min, time 10min), repeat several times until the upper layer is turbid, and collect the upper layer. Finally, through dialysis and ultrasonic treatment, the nanocellulose whisker aqueous suspension is prepared.

[0026] (2) Conversion of nanocellulose aqueous suspension dispersion medium

[0027] Centrifuge the nanocellulose aqueous suspension (the speed is 4000r / min, experience shows that at this speed, the nanocellulose will settle in the lower layer of the centrifuge tube without causing agglomeration;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com