Modified polylactic acid fiber and preparation method thereof

A polylactic acid fiber, polylactic acid technology, applied in the chemical characteristics of fibers, melt spinning, rayon manufacturing and other directions, can solve the problems of short service life, poor wear resistance, spinning difficulties, etc., and achieve excellent flexibility and cheap raw materials. , the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

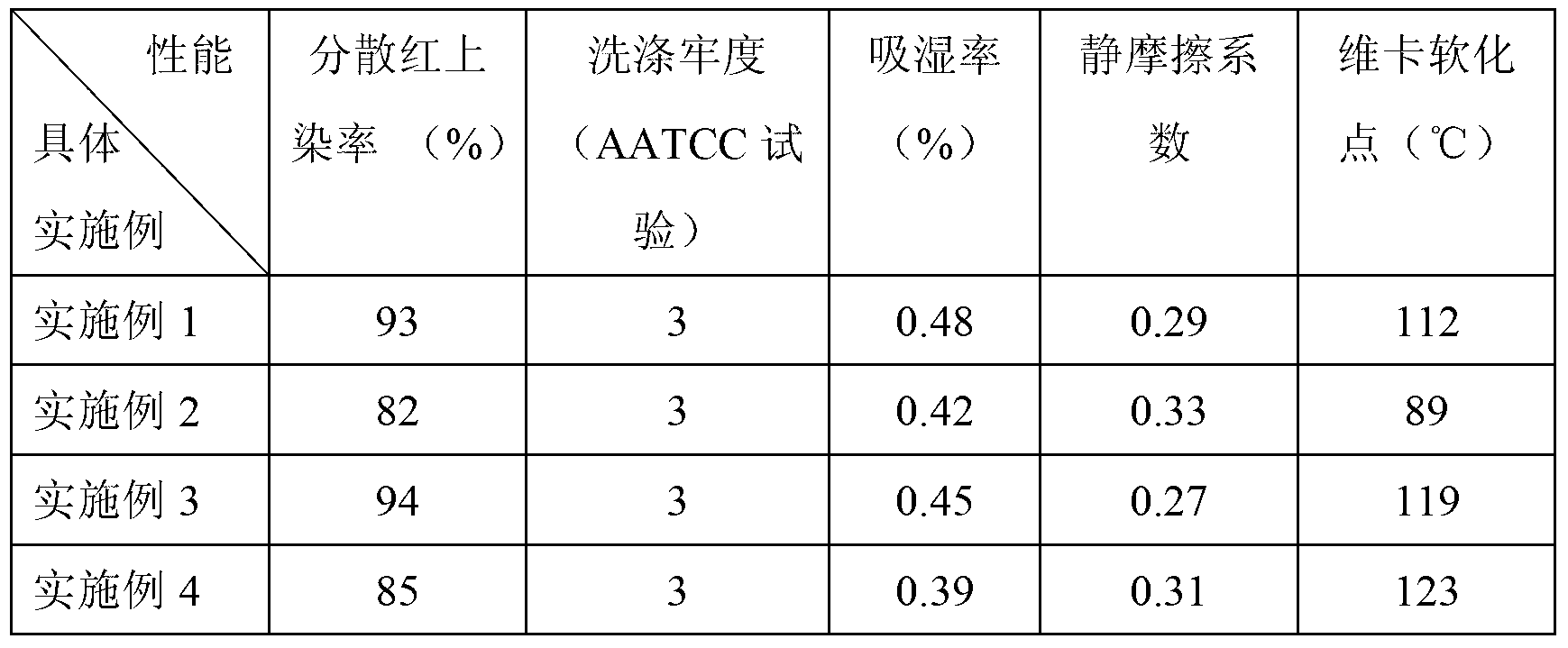

Examples

Embodiment 1

[0036] Vacuum-dry the polylactic acid slices until the water content is 30-150ppm; 22 parts of polylactic acid; 8 parts of ethyl cellulose; 4 parts of cellulose diacetate grafted polylactic acid copolymer; 5 parts of polyoxyethylene wax; 0.5 part; 0.3 part of nucleating agent; 0.2 part (weight fraction) of antioxidant was added to the high-speed mixer, and the modified polylactic acid mixture was obtained after high-speed dispersion for 30 minutes; the uniformly mixed modified polylactic acid mixture was extruded through a twin-screw Melt blending and extrusion to prepare modified polylactic acid functional masterbatch slices, and vacuum dry to a moisture content of 30-150ppm;

[0037] Put 40 parts of the above-mentioned modified polylactic acid functional masterbatch chips and 60 parts of vacuum-dried polylactic acid chips into a high-speed mixer and dry mix for 5 minutes, and the mixture is spun on a melt spinning machine through circular spinneret holes to obtain modified po...

Embodiment 2

[0040] Vacuum-dry the polylactic acid slices until the moisture content is 30-150ppm; 22 parts of polylactic acid; 8 parts of methyl cellulose; 4 parts of polylactic acid copolymer grafted with cellulose diacetate; 5 parts of fatty alcohol polyoxyethylene ether; 0.5 part of talc powder; 0.3 part of nucleating agent; 0.2 part of antioxidant (weight fraction) was added to the high-speed mixer, and the modified polylactic acid mixture was obtained after high-speed dispersion for 30 minutes; the uniformly mixed modified polylactic acid mixture was passed through a double The modified polylactic acid functional masterbatch slices were prepared by melt blending and extruding with a screw extruder, and dried in vacuum until the moisture content was 30-150ppm;

[0041] Put 40 parts of the above-mentioned modified polylactic acid functional masterbatch chips and 60 parts of vacuum-dried polylactic acid chips into a high-speed mixer and dry mix for 5 minutes, and the mixture is spun on a...

Embodiment 3

[0044] Vacuum-dry the polylactic acid slices until the water content is 30-150ppm; 22 parts of polylactic acid; 8 parts of cellulose acetate butyrate; 4 parts of cellulose diacetate grafted polylactic acid copolymer; 5 parts of polyoxyethylene wax; 0.5 parts of powder; 0.3 parts of nucleating agent; 0.2 parts of antioxidant (weight fraction) were added to the high-speed mixer, and the modified polylactic acid mixture was obtained after high-speed dispersion for 30 minutes; the uniformly mixed modified polylactic acid mixture was passed through the twin-screw The modified polylactic acid functional masterbatch slices are prepared by melt blending and extruding in an extruder, and vacuum-dried to a moisture content of 30-150ppm;

[0045] Put 40 parts of the above-mentioned modified polylactic acid functional masterbatch chips and 60 parts of vacuum-dried polylactic acid chips into a high-speed mixer and dry mix for 5 minutes, and the mixture is spun on a melt spinning machine thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com