Gas purification process and system

A purification process, gas technology, applied in the direction of combustible gas purification, combustible gas purification/transformation, chemical industry, etc., can solve the problems of affecting the secondary recycling of dust, affecting the recovery rate of tar, poor dust separation effect, etc., to reduce equipment Investment and production costs, improving quality and recycling efficiency, and reducing the difficulty of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, device of the present invention is further explained:

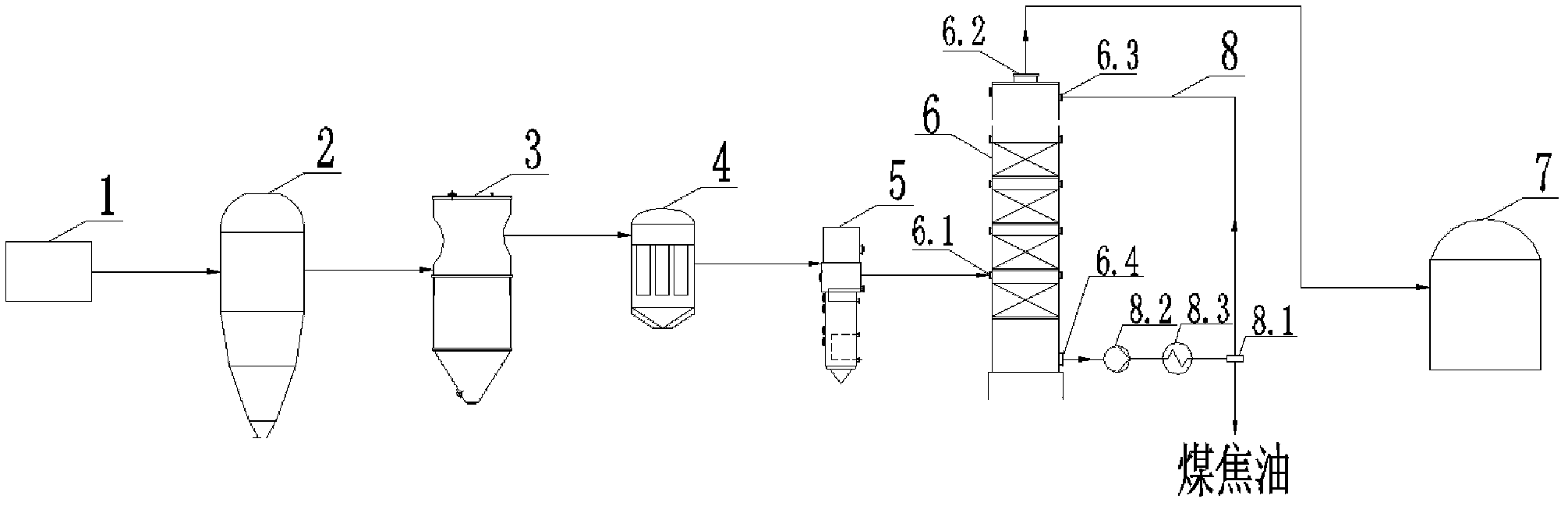

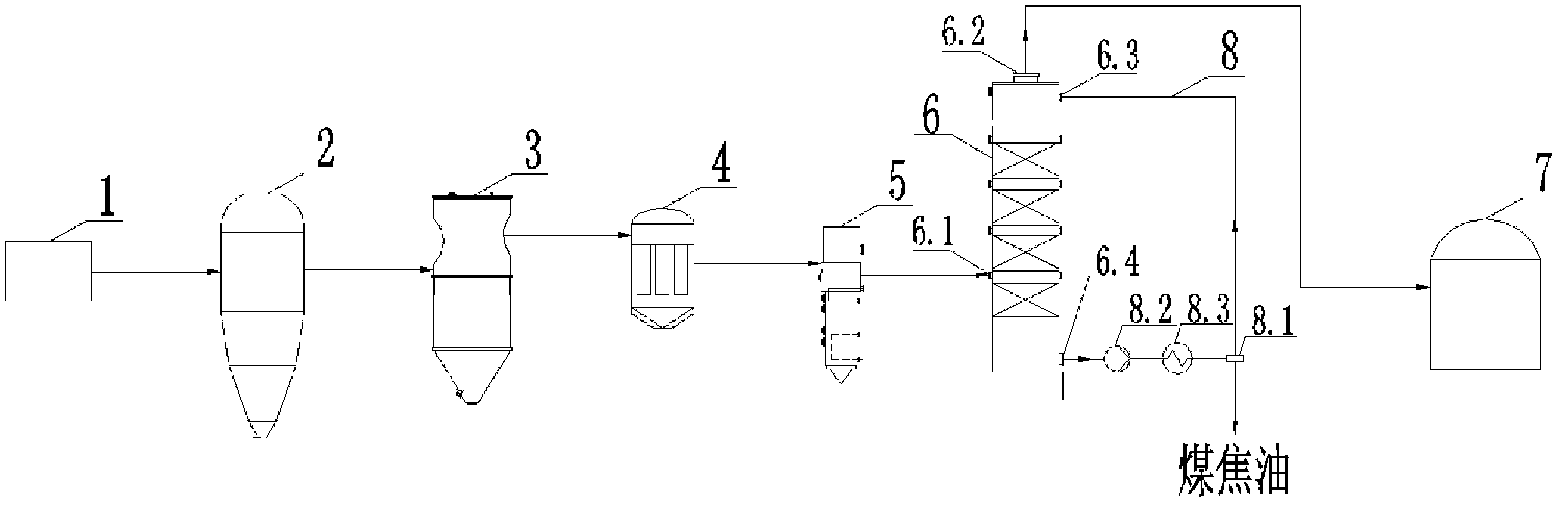

[0026] refer to figure 1 , a dryer 1, a pyrolysis furnace 2, a high-temperature cyclone separator 3, a high-temperature ceramic filter 4 (or a high-temperature sintered metal filter), a waste heat boiler 5 and a quenching tower 6 connected in sequence by pipelines, the quenching tower 6 The upper section is provided with a gas outlet 6.2 and a coal tar inlet 6.3, and the lower section is provided with a gas outlet 6.1 and a coal tar outlet 6.4, the gas outlet 6.2 is connected to the gas cabinet 7, and the coal tar outlet 6.4 is connected to the coal tar inlet 6.3 through a circulation pipeline 8. The circulation pipeline 8 is also provided with a centrifugal pump 8.2, a coal tar cooler 8.3 and a diversion port 8.1 that can be connected with the coal tar product tank

[0027] Process method:

[0028] The raw coal is sent to the dryer 1 for pre-drying, and the dried ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com