Microwave plasma biomass gasification fixed-bed gasification furnace and process

A technology of fixed bed gasification furnace and microwave plasma, which is applied in the field of gasification technology, can solve the problems of corrosion, low gasification temperature, and high tar content, and achieve the effect of no complicated treatment, simple and reliable process, and low tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with implementation examples and accompanying drawings, but the present invention is not limited.

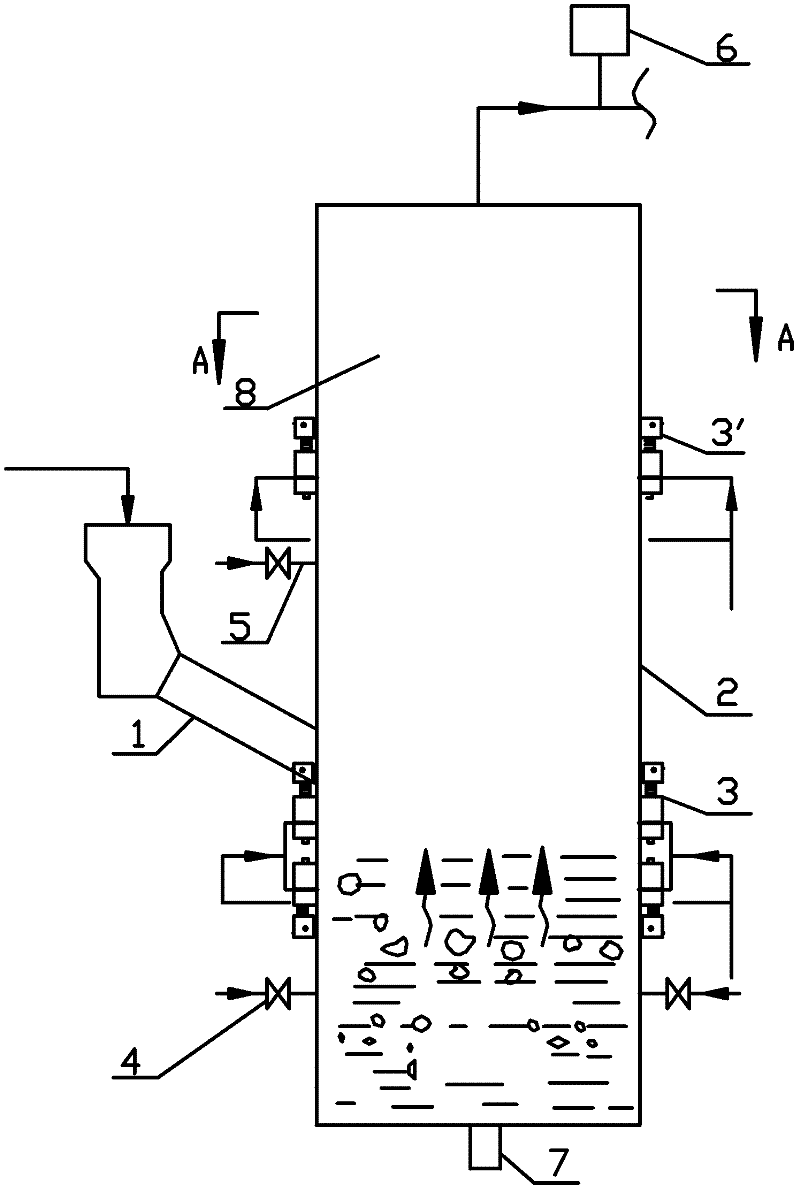

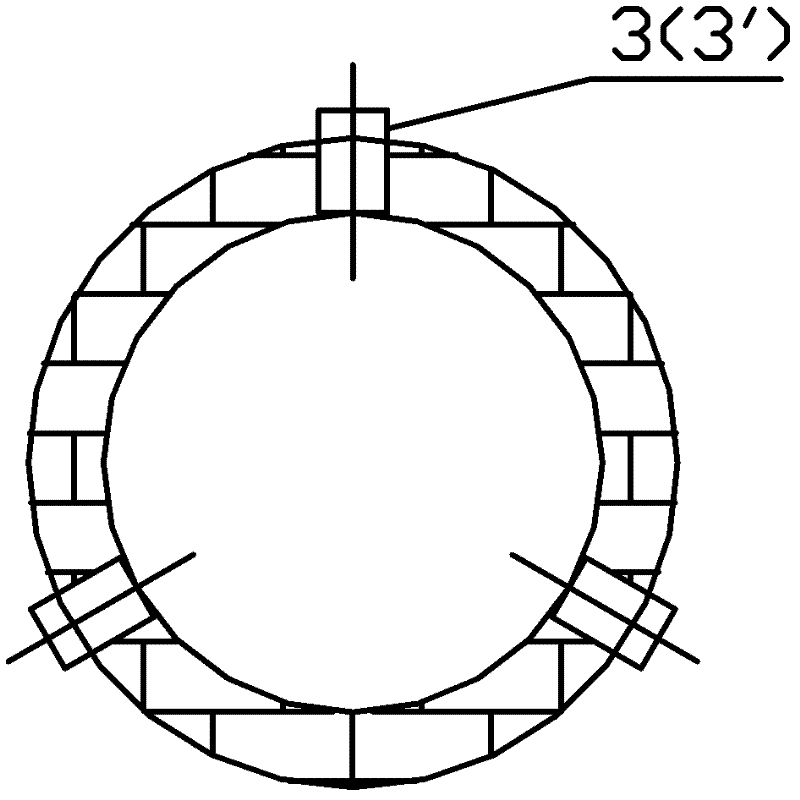

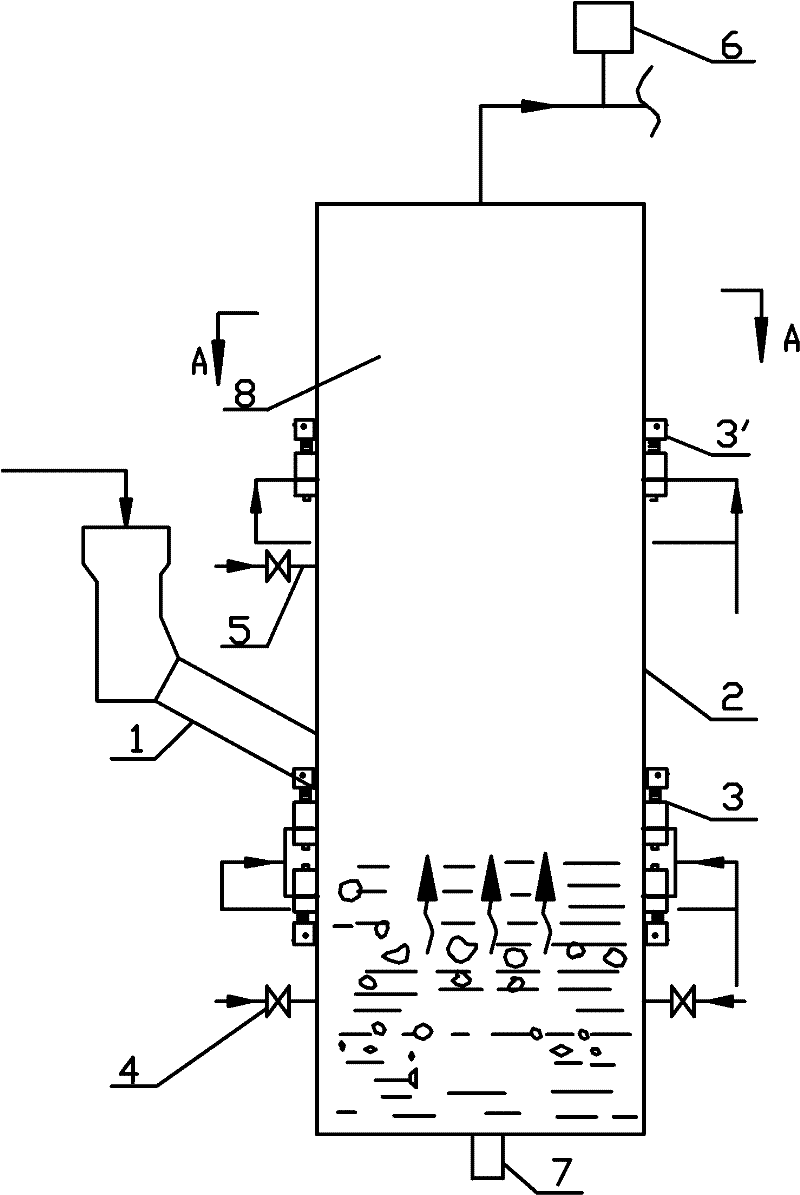

[0030] The gasifier body 2 is a vertical cylinder, the uppermost part is the gasifier clearance zone 8, the lowermost part is the microwave plasma fixed bed, and the lowermost end of the fixed bed is provided with a vertically downward slag outlet 7; Outside the gasifier body 2, the upper oxygen / steam nozzle 5 is arranged on the periphery of the clearance area 8, and the lower oxygen / steam nozzle 4 is arranged on the periphery of the fixed bed. The gasifier body 2 can be a cylinder, or a combination of a cone and a cylinder.

[0031] The feeding device 1 is located in the middle of the gasifier body 2 and communicates with the gasifier body 2 through an inclined feeding slideway; the feeding method can also be a screw feeding method, which does not require an inclined feeding slideway .

[0032] The la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com