Method for producing modified disperse red 60

A production method and a technology for dispersing red, applied in the direction of amino-hydroxyanthraquinone dyes, etc., can solve the problems of increased labor protection difficulty for employees, dry product dust affecting the operating environment, long condensation reaction time, etc., to shorten the condensation reaction time, The effect of eliminating the drying process and drying equipment and accelerating the condensation reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

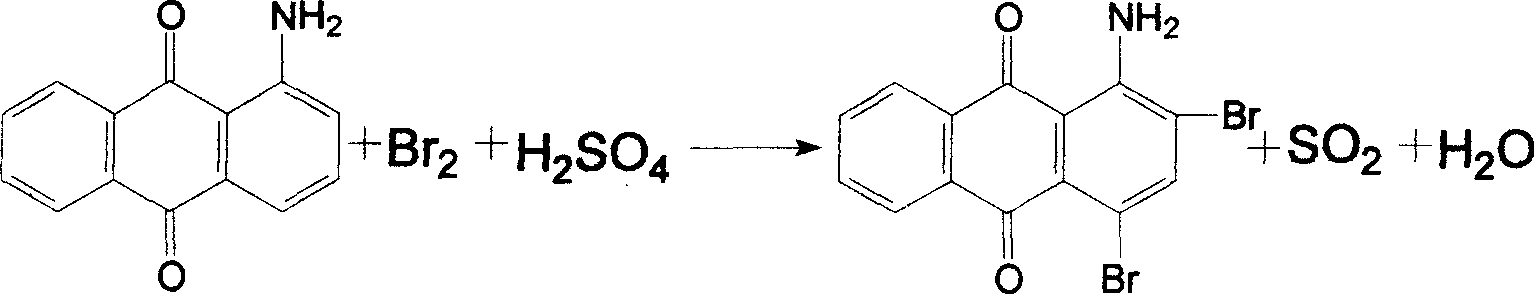

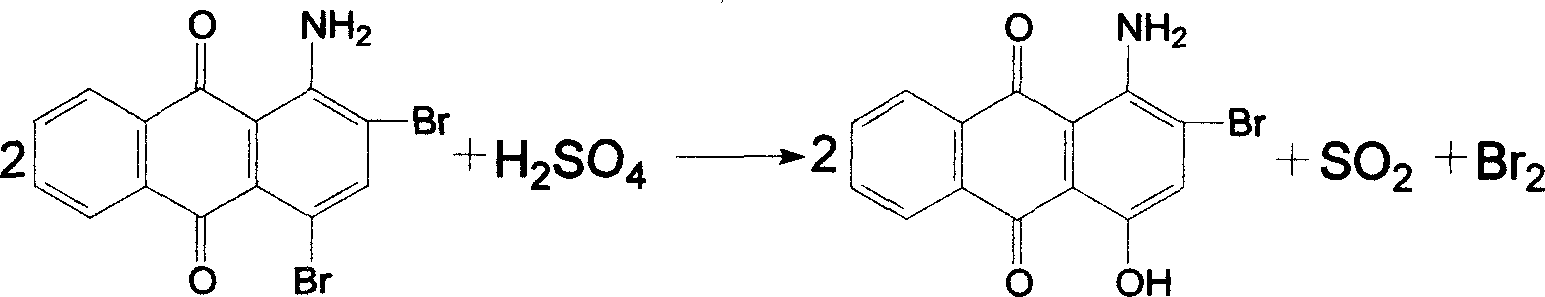

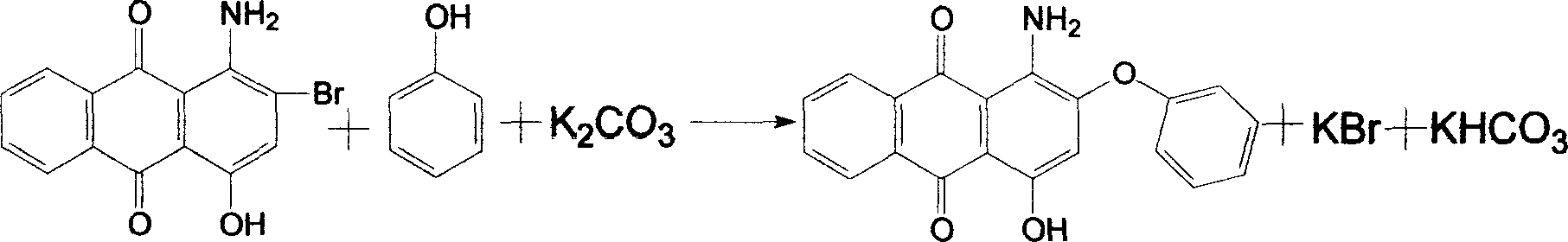

Method used

Image

Examples

Embodiment 1

[0025] Add 1000kg of phenol, 1-amino-2-bromo-4-hydroxyanthraquinone wet product filter cake into 3000L enamel kettle, fold dry 500kg, solvent chlorobenzene 600kg, heat up azeotropic dehydration, after the distillate separates the water layer, solvent Automatically flow back into the reaction kettle, add 180kg of acid-binding agent potassium carbonate and 3kg of antioxidant oxalic acid after the distillate is anhydrous, heat up to 148-150°C within 3 hours and keep it warm for condensation reaction for 6 hours, heat up and keep warm After the distillate in the process is collected and stratified, the solvent chlorobenzene is directly used for the next batch of condensation. After the detection reaches the end point of condensation, the temperature is lowered to 95-100°C, and 1300kg of water is added at this temperature, and then 30% liquid caustic soda is added dropwise. 50kg, and finally cooled to 50-52°C to filter and wash to obtain 510kg of Disperse Red 60 finished product, wi...

Embodiment 2

[0027] Add 1000kg of phenol, 1-amino-2-bromo-4-hydroxyanthraquinone wet product filter cake to dry 500kg, solvent chlorobenzene 600kg in a 3000L enamel kettle, heat up azeotropic dehydration, the distillate separates out of the water layer and the solvent automatically Return to the reaction kettle, add 180kg of acid-binding agent potassium carbonate and 3kg of antioxidant oxalic acid after the distillate is anhydrous, heat up to 150-155°C in 3 hours after the addition and keep it warm for condensation reaction for 5 hours, heat up and keep warm After the distillate in the distillate is collected and stratified, the solvent chlorobenzene is directly used for the next batch of condensation. After the detection reaches the end point of the condensation, the temperature is lowered to 95-100°C. At this temperature, 1300kg of water is added, and then 30kg of 30% liquid caustic soda is added dropwise. Finally, the temperature was lowered to 50-52° C., filtered and washed to obtain 50...

Embodiment 3

[0029] Add 1,200kg of phenol, 500kg of 1-amino-2-bromo-4-hydroxyanthraquinone wet product filter cake, and 500kg of solvent chlorobenzene into a 3000L enamel kettle. Return to the reaction kettle, add 180kg of acid-binding agent potassium carbonate and 5kg of antioxidant oxalic acid after the distillate is anhydrous, heat up to 148-150°C in 3 hours after the addition and keep it warm for condensation reaction for 6 hours, heat up and keep warm After the distillate is collected and stratified, the solvent chlorobenzene is directly used for the next batch of condensation. After the detection reaches the end point of the condensation, the temperature is lowered to 95-100°C, the temperature is controlled, and 1500kg of water is added at this temperature, and then 30% liquid caustic soda is added dropwise. 50kg, finally warmed slowly to 50-52°C, filtered and washed to obtain 500kg of finished product, with a yield of 96% and a content of 99.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com