Biomass mixing and gasifying process and apparatus

A process method and biomass technology, which is applied in the petroleum industry, the manufacture of combustible gas, special forms of dry distillation, etc., can solve problems such as the problem of tar in gasifiers that cannot be solved well, so as to increase production and use, and improve flexibility and adaptability , the effect of reducing tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

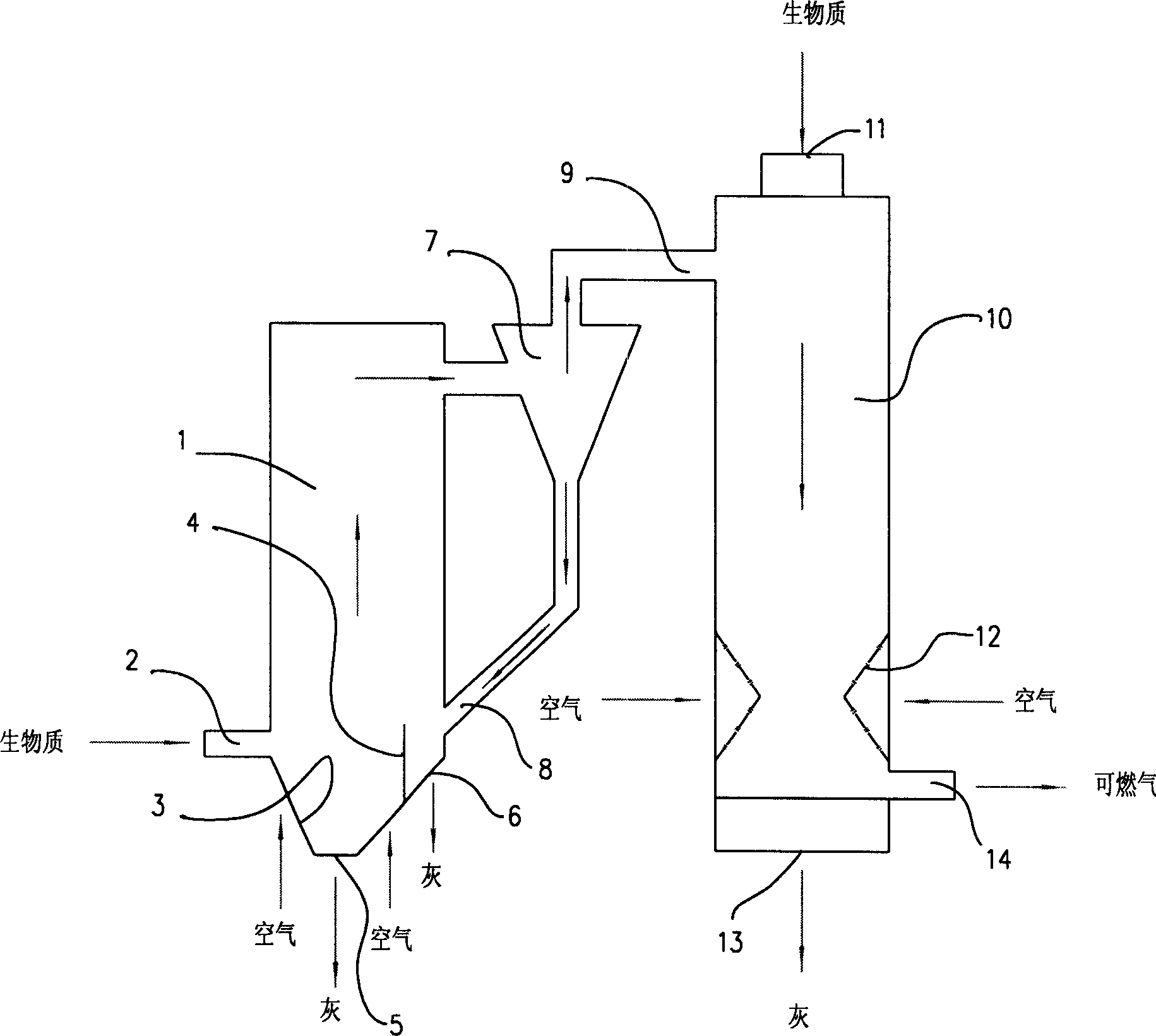

[0015] The structure of the gasification device embodiment of the present invention is as attached figure 1 As shown, the gasification device is composed of a circulating fluidized bed gasifier 1 and a downdraft gasifier 10 to form a composite gasifier, and a cyclone separator 7 is arranged on the side of the circulating fluidized bed gasifier 1 to circulate The fluidized bed gasification furnace 1 has an independent feed inlet 2, the lower part of the furnace is the air distribution plate 3 and the ash outlet 5, the air inlet of the cyclone separator 7 is connected with the gas outlet of the upper part of the circulating fluidized bed gasification furnace 1 The fly ash return pipe 8 at the bottom of the cyclone separator 7 is connected to the fly ash outlet 6 separated by the partition plate 4 at the lower part of the circulating fluidized bed gasifier, and the gas outlet of the cyclone separator 7 is connected to the lower part of the cyclone separator 7. The combustible ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com