Biomass high-temperature flue gas gasification combination coal burning boiler and low-pollution combustion method thereof

A coal-fired boiler and high-temperature flue gas technology, applied in the field of coal-fired boilers, can solve the problems of high emission concentration, lower boiler output, lower ash melting point, etc., and achieve the effects of reducing NOX concentration, reducing tar content, and reducing slagging tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention provides a biomass high-temperature flue gas gasification combined coal-fired boiler and its low-pollution combustion method. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

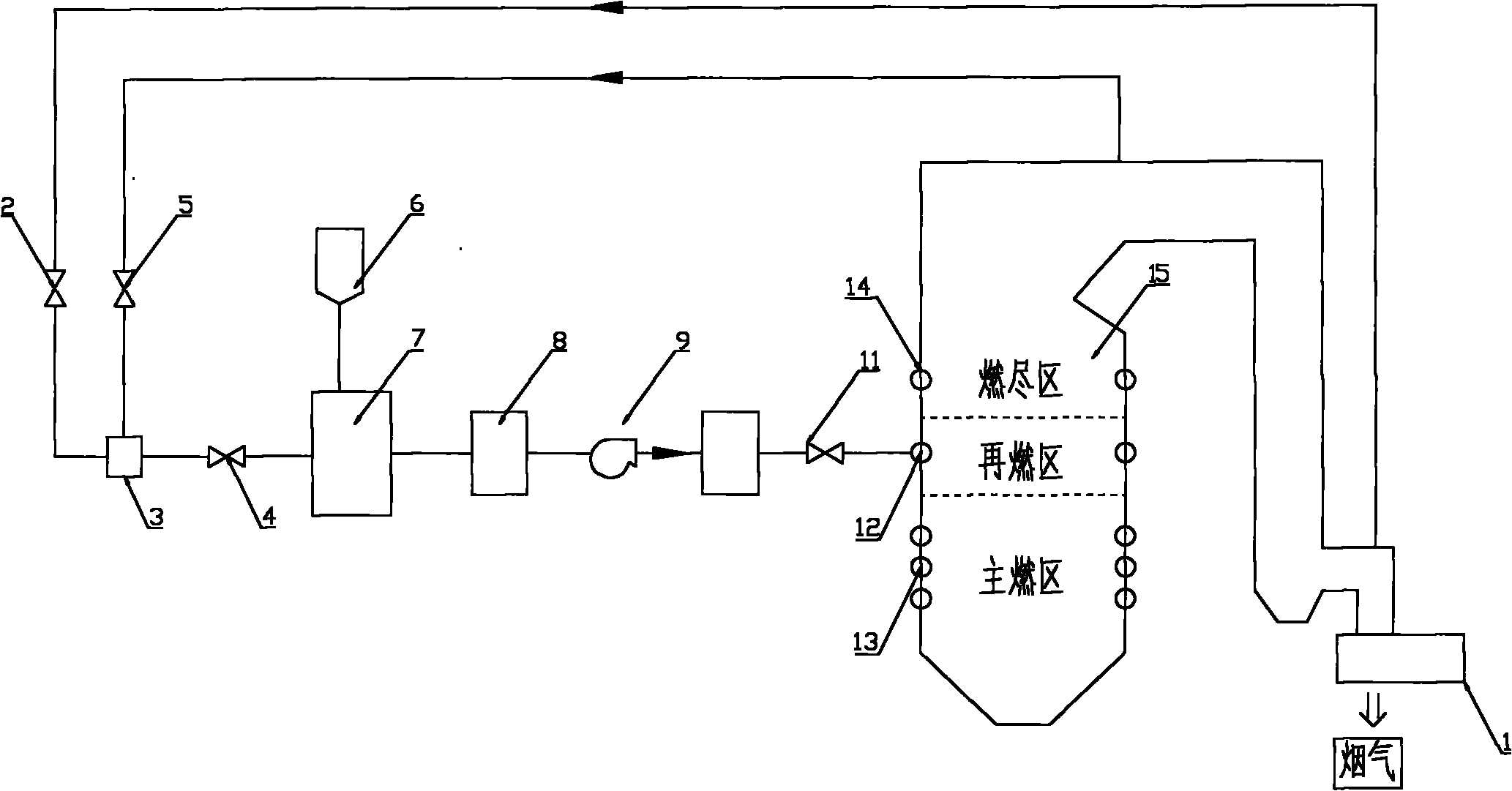

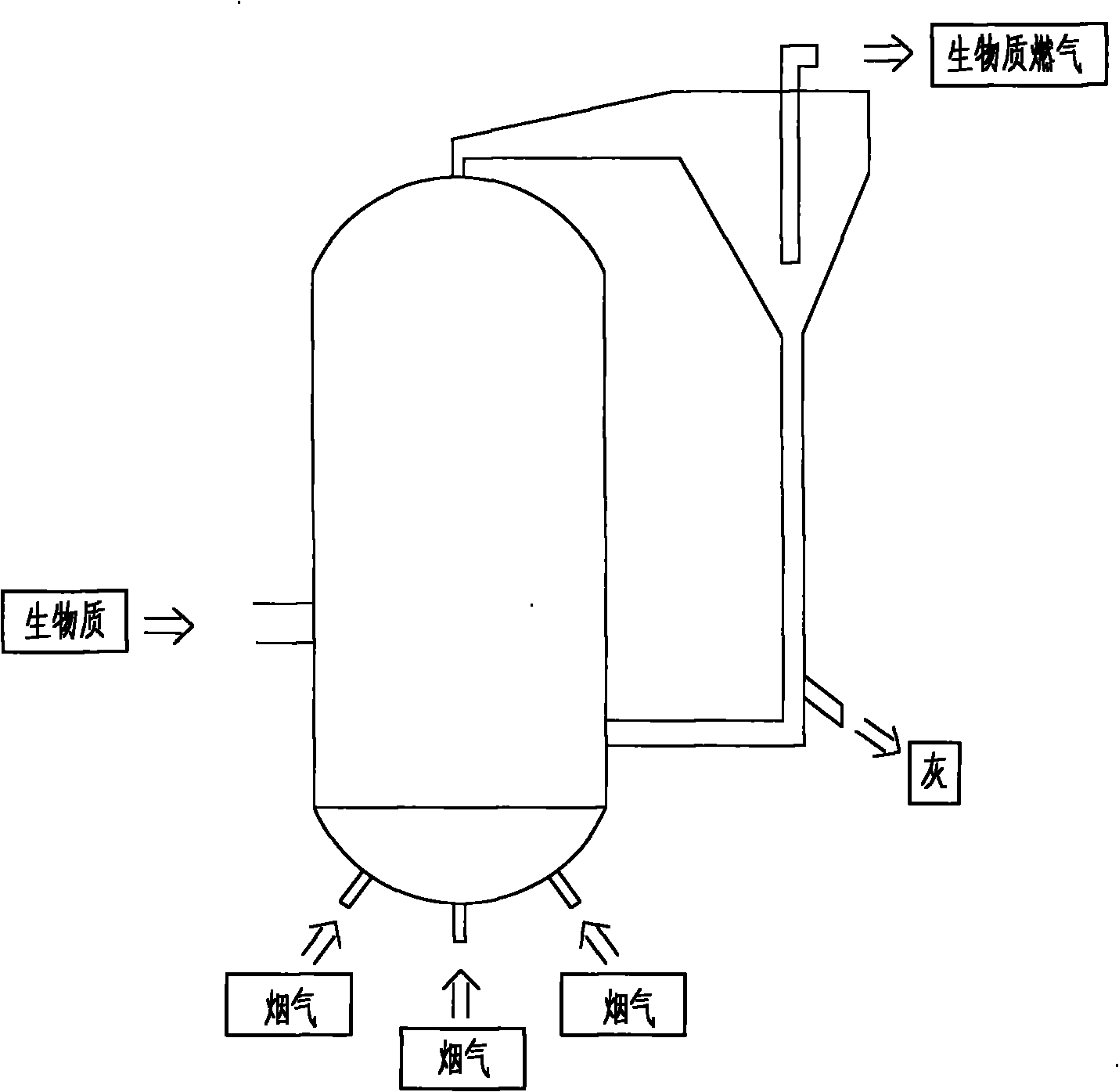

[0029] Such as figure 1As shown, the furnace outlet of the coal-fired boiler 15 leads to a high-temperature flue gas pipe, and the air preheater 1 of the coal-fired boiler 15 leads to a low-temperature flue gas pipe before the flue gas inlet, and the two flue gas pipes are jointly connected to the flue gas mixer 3 , the flue gas mixer 3 is sequentially connected with the gasifier 7, the gas purification chamber 8, the booster fan 9, and the gas storage tank 10, and finally passes into the reburning zone of the coal-fired boiler 15; the gasifier 7 is connected with a biomass bin 6. A low-temperature flue gas damper 2 is set between the coal-fired boiler 15 and the flue gas mixer 3, a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com