Fluidized-bed gasification reaction device with independent combustion chamber and fluidized-bed gasification reaction method

A technology of fluidized bed gasification and independent combustion chamber, which is applied to the gasification of granular/powdered fuels, the manufacture of combustible gas, and the petroleum industry. High volume and other problems, to achieve the effect of improving efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

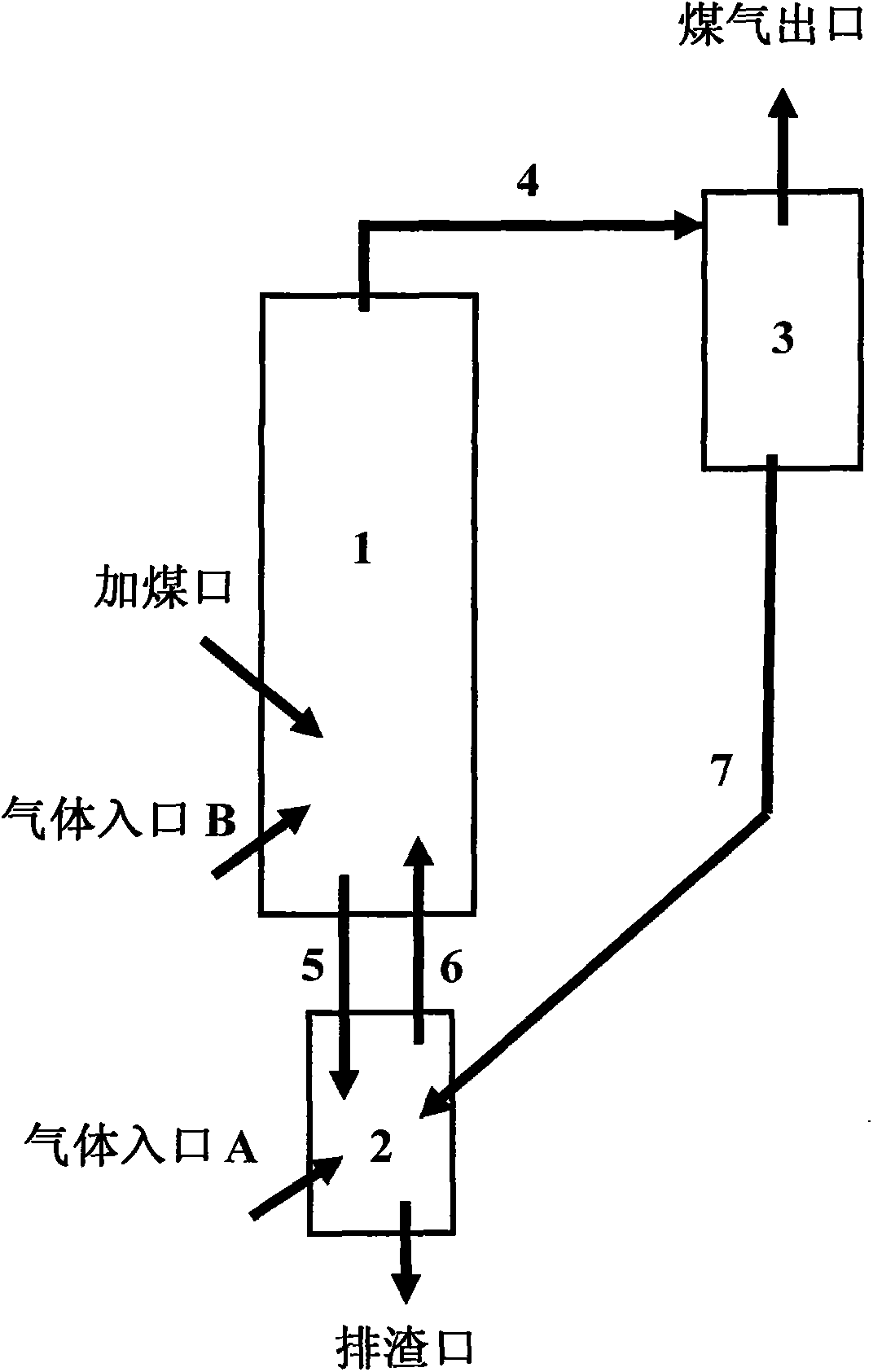

[0036] Fluidized bed gasification reaction device with independent combustion chamber, if attached figure 1As shown, the device consists of fluidized bed gasifier 1, combustion chamber 2, gas-solid separator 3, crude gas pipe 4, bottom slag introduction pipe 5, high-temperature gas pipe 6, gas inlet A, gas inlet B, coal addition Port, slagging port and gas outlet, wherein crude gas pipe 4 connects fluidized bed gasifier 1 with gas-solid separator 3, fluidized bed gasifier 1 and combustion chamber 2 are set separately, bottom slag introduction pipe 5 The high-temperature gas pipe 6 connects the fluidized bed gasification furnace 1 with the combustion chamber 2 , and the fly ash circulation pipe 7 connects the gas-solid separator 3 with the combustion chamber 2 .

[0037] In this embodiment, the raw coal is fed into the fluidized bed gasification furnace 1 from the coal inlet, and the crude gas is obtained after reacting with the gasification agent. The fly ash is sent into the...

Embodiment 2

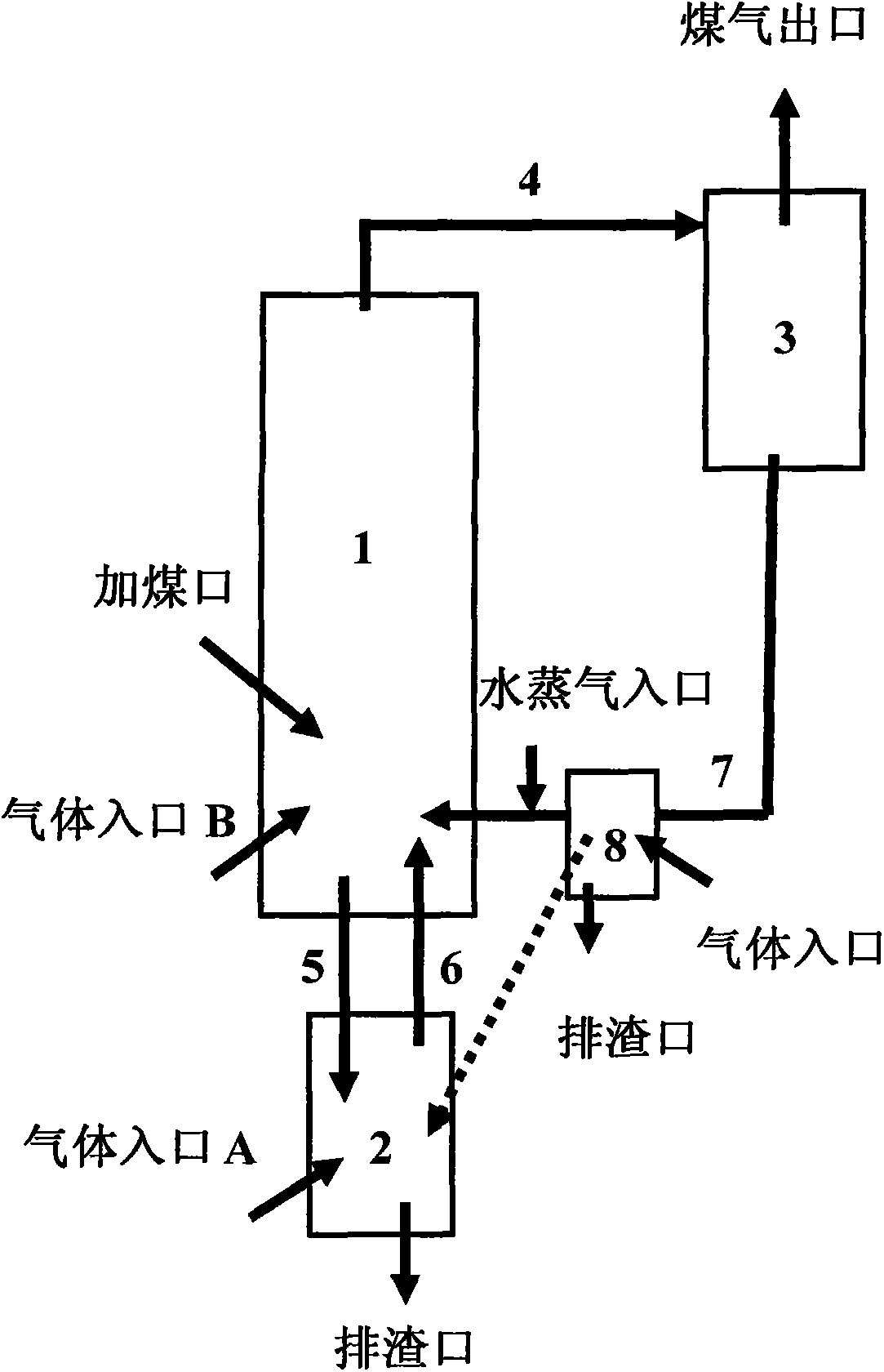

[0039] This embodiment is an improved device of embodiment 1, as attached figure 2 As shown, there can be two fly ash circulation modes in this example: (1) In addition to adding a fly ash combustion device 8 on the fly ash circulation pipe 7 (passing oxygen-containing gas to it, and discharging ash), The connecting pipeline between the combustion device 8 and the fluidized bed gasification furnace 1 is provided with a water vapor inlet, and the fly ash circulation pipe is connected to the gasification furnace 1, and the remaining parts are the same as in Example 1; 7 is set up fly ash combustion device 8 (passes into it oxygen-containing gas, and discharges ash) except that the rest is the same as embodiment 1. One of the modes can be selected during specific implementation.

[0040] In this embodiment, the fly ash and the bottom slag are subjected to high temperature and oxidation treatment by corresponding combustion mechanisms respectively. In addition to the advantages ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com