Technical process for gasification of fluidized-bed CO gasifying furnace and apparatus thereof

A fluidized bed gasifier and gasifier technology, applied in the field of coal chemical industry, can solve the problems of high raw material prices, low balance components, and difficulty in high-content CO raw material gas, so as to achieve fast reaction speed, improve environmental conditions, The effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

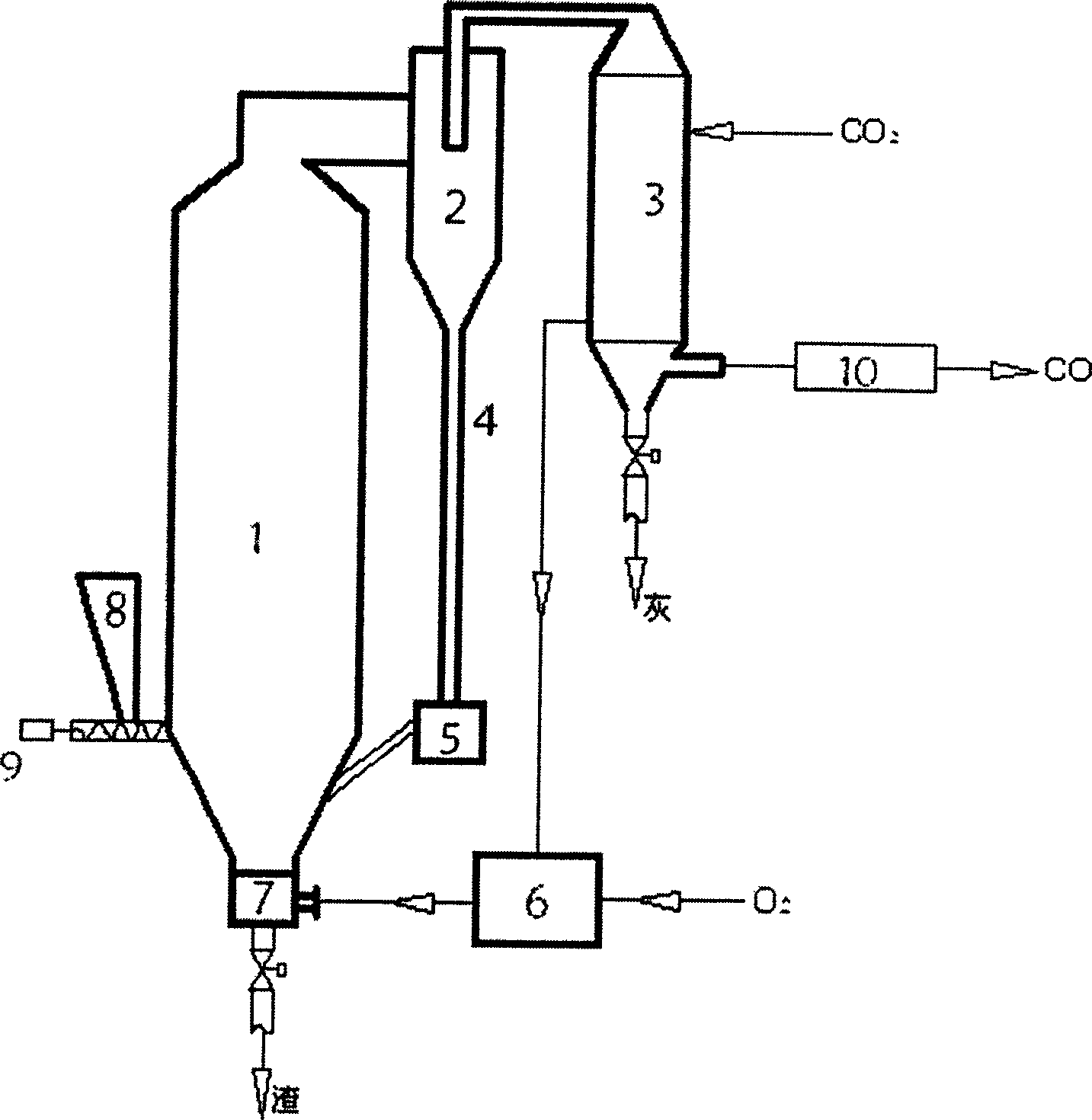

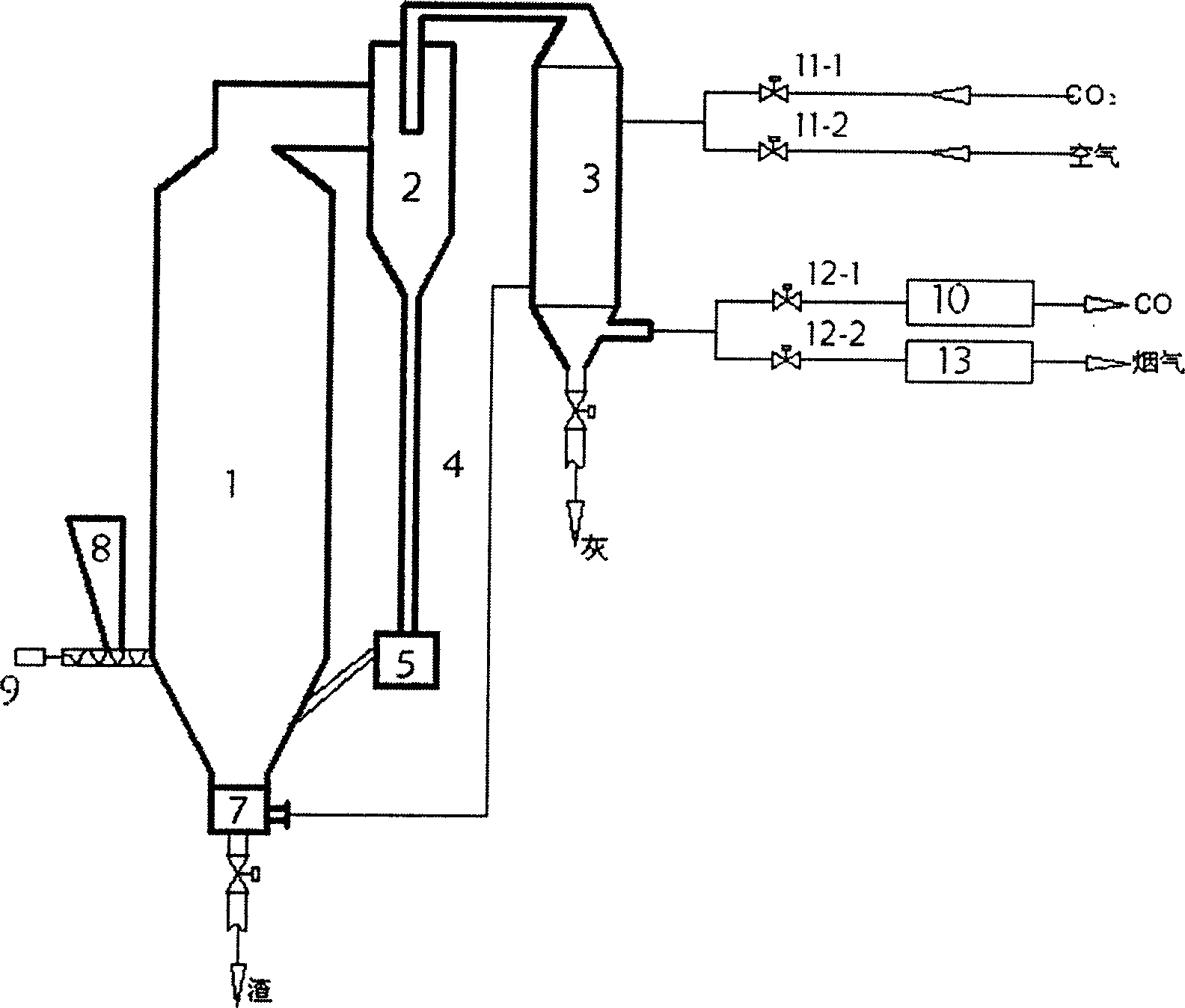

[0018] 1. Fluidized bed continuous gasification method

[0019] like figure 1 As shown, the process is based on pure oxygen (≥98%) and CO 2 The gas is mixed as a gasification agent, and the coke powder of 0-10mm is used as a raw material to be sent into the gasifier (1) through a screw stoker (9), and the CO 2 After the gas is heated to 600°C by the tubular heat exchanger (3), it is mixed with oxygen in proportion by the Venturi mixer (6), and then enters the gasifier (1) from the air chamber (7), so that the carbon in the furnace layers in the fluidized state with O 2 and CO 2 The oxidation-reduction reaction is carried out at high temperature to generate CO gas. Since this reaction is an exothermic and endothermic reaction, the bed temperature should drop. When the two reactions are in heat balance, the bed temperature is in a stable state. The temperature depends on the ash melting point of coal char, and generally does not exceed 1150°C. The generated high-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com