Method for gasifying cyclone bed powder coal

A swirling bed and pulverized coal technology, which is applied in the field of swirling bed pulverized coal gasification, can solve the problems of many equipment, low carbon conversion rate and gas calorific value, and is not suitable for coals with high ash content, etc. The effect of large size, simple equipment structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

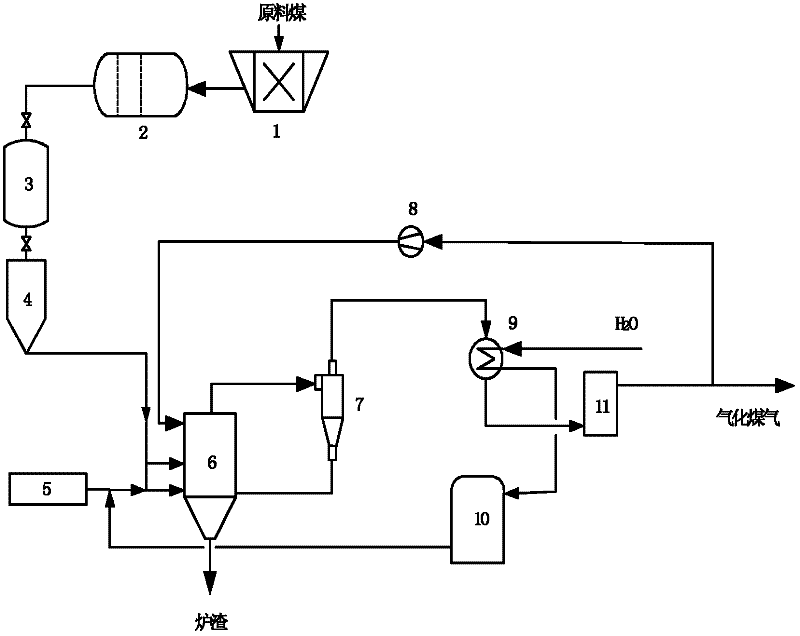

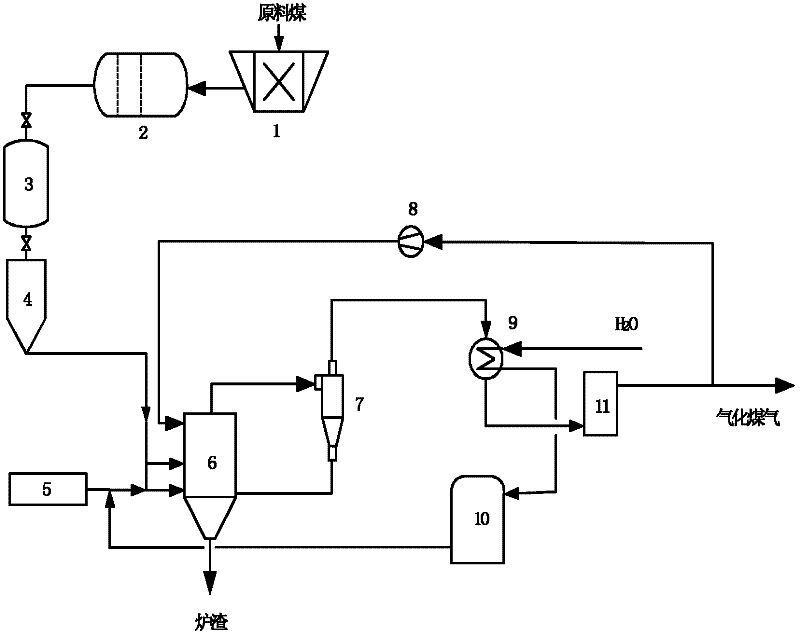

[0021] Taking the production scale of coal processing capacity of 2t / h as an example, the raw coal is crushed by the crusher (1) into a particle size of ≤1mm, and then dried in the drying preheater (2) to a total moisture content of 8%. After preheating, the temperature 250°C; the dried and preheated coal powder passes through the coal lock hopper (3) and the coal bunker (4) in turn, and is jointly acted by the oxygen from the oxygen generation system (5) and the water vapor from the high-pressure steam boiler (10) The lower part enters the swirling bed gasifier (6) in the upper and lower paths, and gasification reaction is carried out under the conditions of pressure 1.0MPa and temperature 1000°C to prepare coal gas; the produced high-temperature gas is excited in the upper part of the swirling bed gasifier (6). Cold, chilled air comes from the chilled air compressor (8); the chilled gas enters the cyclone dust collector (7) from the top of the swirl bed gasifier (6) for dust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com