Method and device for producing hydrogen through biomass gasification by using single fluidized bed and two-step method

A fluidized bed gasifier and fluidized bed technology, applied in the energy field, can solve the problems of low gasification efficiency, difficult quantitative control, bed temperature change, etc., and achieve the effect of saving investment and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

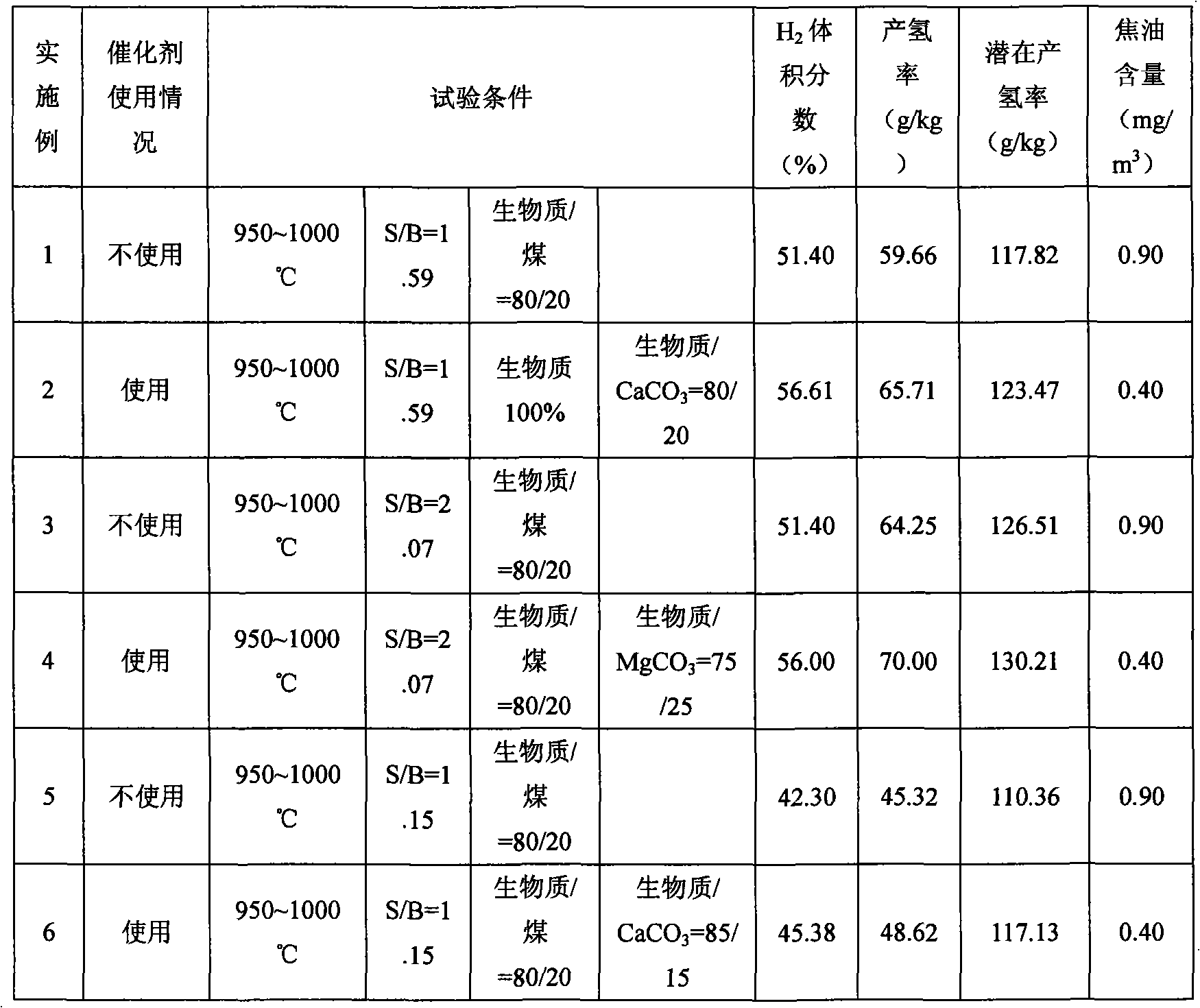

Examples

Embodiment Construction

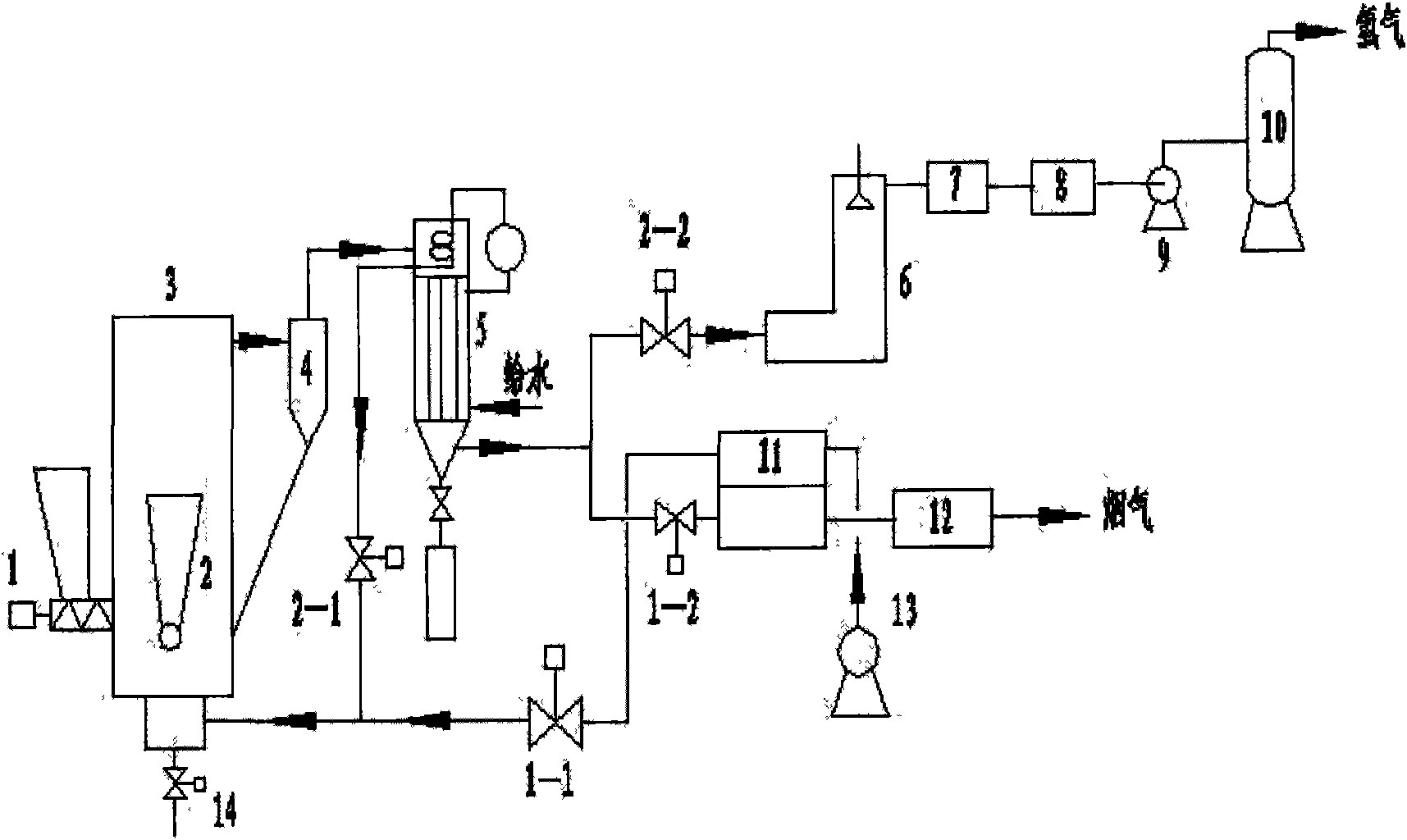

[0014] The single fluidized bed two-step gasification hydrogen production device of the present invention takes the fluidized bed gasification furnace 3 as the core, and the fluidized bed gasification furnace 3 is provided with two spiral feeding devices, that is, the biomass feeding device 1 and the coal Feeding device 2, and ash discharge device 14. At the inlet end of the fluidized bed gasifier, the air reversing valve 1-1, the steam reversing valve 2-1, the flue gas reversing valve 1-2 at the outlet end, and the gas reversing valve 2-2 are used as connection points, and the equipment is connected It is connected as two working systems, that is, the combustion system and the gasification system of the gasifier. Its combustion system includes: Roots blower 13, air preheater 11, air reversing valve 1-1, fluidized bed gasifier body 3, high temperature cyclone separator 4, waste heat boiler and steam superheater 5, which are connected in sequence. Flue gas reversing valve 1-2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com