Low activity dust coal catalytic gasifying method

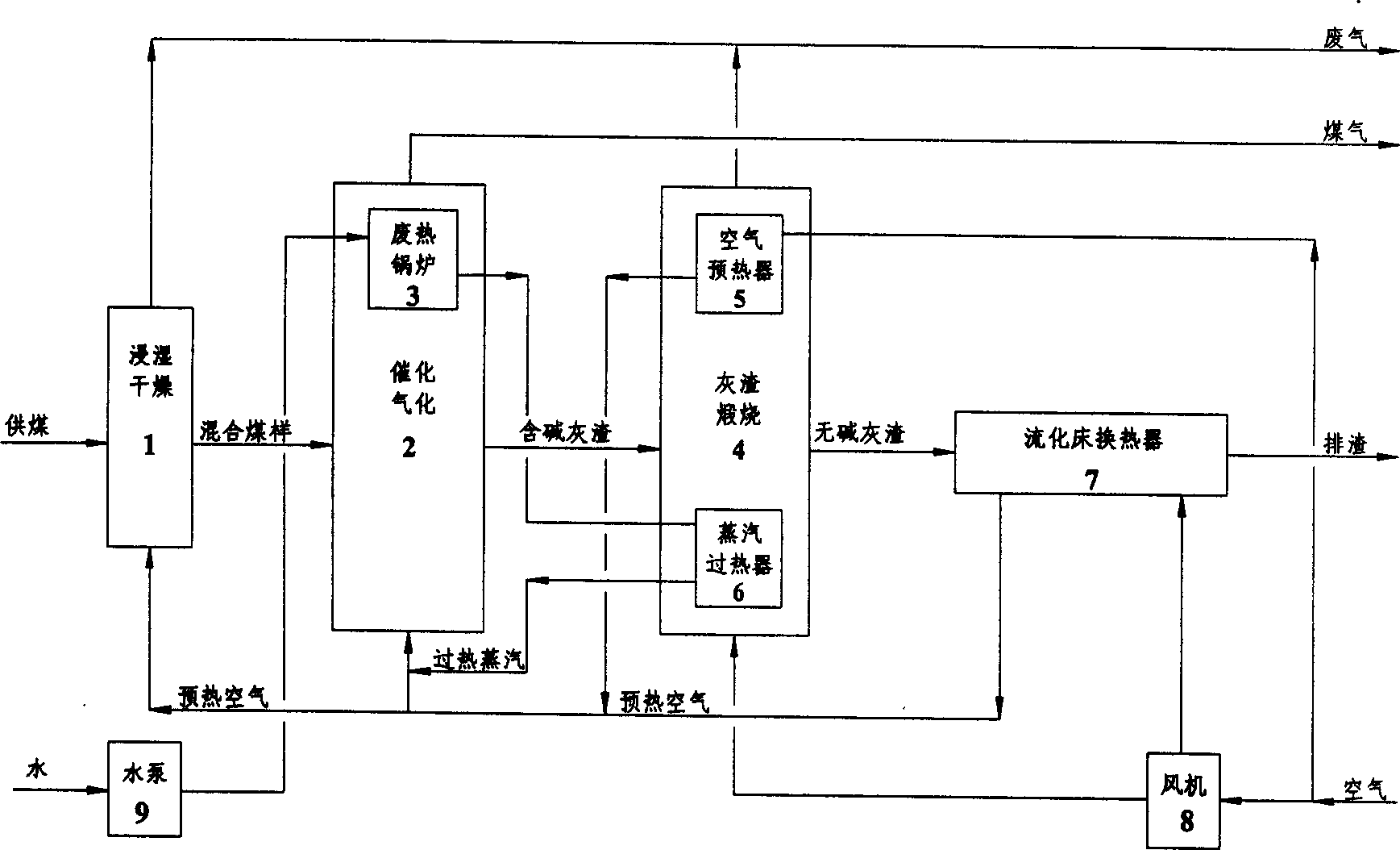

A low-activity, pulverized coal technology, used in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve problems such as unapplied value, uneven distribution of coal mines, and block coal mining at different prices, restricting sustainable development, etc. The effect of gasification reaction rate and gas yield, ensuring continuous circulation and stable operation, efficient gasification and residue conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Spray the industrial waste lye under normal temperature into a packing particle size of 0.8-2.0 mm and Fujian Shangjing anthracite pulverized coal (volatile matter V ad %=2.69%, Ash A ad %=18.37%) stirred bed, wherein the total volume of spent caustic soda is based on the filling amount of submerged pulverized coal or carbonized coal char, and the Na content is converted into NaOH, which accounts for 3.8% of the weight of pulverized coal or carbonized coal char, at 110 Mix and dry at ℃ for 8 hours to obtain a mixed coal sample;

[0028] (2) The mixed coal sample enters the fluidized bed gasifier, and under the conditions of gasification temperature of 850 ° C and gasification time of 50 min, it is mixed with water vapor from the fluidized bed calciner and preheated air, and then the water vapor / air =1.4kg / m 3 And water / coal=2kg / kg for catalytic gasification, the gas yield can be obtained 3.18Nm after testing 3 / kg Coal and gas calorific value 7.07MJ / m 3 As a res...

Embodiment 2

[0032] (1) 2% pulp black liquor at room temperature (converted into the amount of NaOH to account for coal weight) and Fujian Yongding anthracite powdered coal with a particle size of 1.0-4.0 mm (volatile content V ad %=3.56%, Ash A ad %=19.94%) for impregnation, and then dried for 4 hours in a tumble dryer at 120°C to obtain a mixed coal sample;

[0033] (2) The mixed coal sample enters the fluidized bed gasifier, and under the conditions of gasification temperature of 880 °C and gasification time of 40 min, it is mixed with water vapor from the fluidized bed calciner and preheated air, and then the water vapor / air =1.1kg / m 3 And water / coal=1.6kg / kg for catalytic gasification, the gas yield can be obtained 4.33Nm after testing 3 / kg Coal and gas calorific value 7.01MJ / m 3 As a result, alkaline ash can be automatically discharged from the bottom or side of the gasifier;

[0034] (3) The bauxite, which accounts for 2% of the alkaline ash weight, is mixed with the alkaline a...

Embodiment 3

[0037] (1) Spray the waste lye of viscose at normal temperature into an anthracite pulverized coal in Shangjing, Fujian with a particle size of 3.0-5.0 mm ad %=2.69%, Ash A ad %=18.37%) stirred bed, wherein the total volume of spent caustic soda is based on the filling amount of submerged pulverized coal or carbonized coal char, and the Na content is converted into NaOH, which accounts for 5.0% of the weight of pulverized coal or carbonized coal char, at 120 Mix and dry at ℃ for 6 hours to obtain a mixed coal sample;

[0038] (2) The mixed coal sample enters the fluidized bed gasification furnace, and under the conditions of gasification temperature of 900 ° C and gasification time of 60 minutes, it is mixed with water vapor (water / coal = 4.5kg / kg) from the fluidized bed calciner. Catalytic gasification, after testing, the gas yield can be 3.4Nm 3 / kg Coal and gas calorific value 9.3MJ / m 3 As a result, alkaline ash can be automatically discharged from the bottom or side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com