Biomass fluid bed gasification furnace using heat pipe supplying heat

A fluidized bed and biomass technology, applied in coking ovens, special dry distillation, petroleum industry, etc., can solve the problems of low calorific value, high cost, complex structure and operation of combustible gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

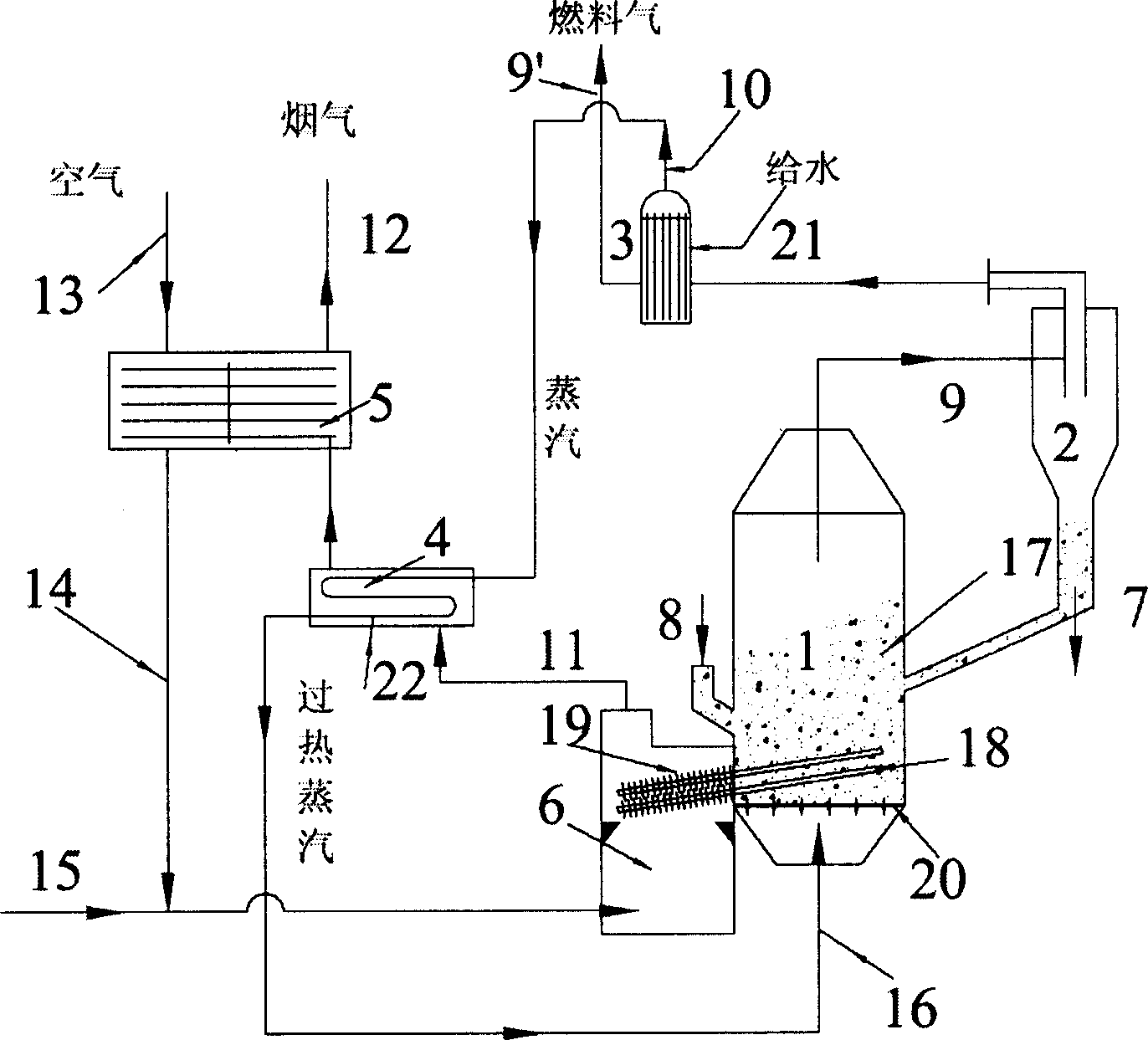

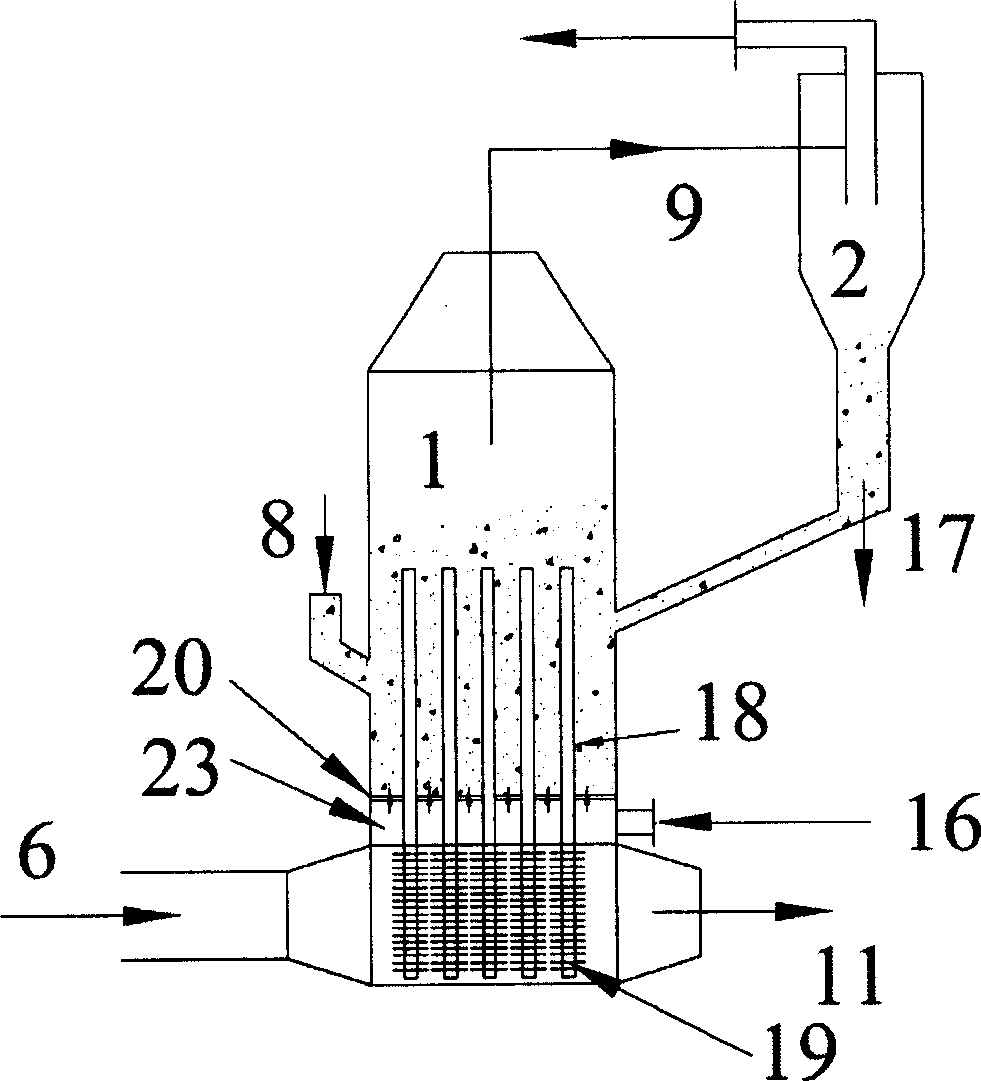

[0014] Attached below figure 1 The present invention is described as follows:

[0015] The present invention is made up of three major parts:

[0016] 1. Biomass circulating fluidized reaction system;

[0017] 2. Biomass reaction heat heat pipe heating system;

[0018] 3. Biomass combustible gas and combustion flue gas waste heat recovery system.

[0019] The reaction device of the present invention is a heat pipe type circulating fluidized bed biomass gasification furnace, which includes a reactor 1, a cyclone separator 2, a heat pipe steam generator 3, a steam superheater 4, an air preheater 5, a combustion Chamber 6; Reactor 1 is provided with feed pipe 8, air inlet 16 and fuel gas outlet 9, and it links to each other with combustion chamber 6 wall, and combustion chamber 6 is below the side of reactor 1, and heat pipe passes reactor 1 and combustion chamber The chamber wall at the connected position of 6 is set in the reactor 1 and the combustion chamber 6, the heat ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com