Fused salt heat accumulating peak regulating system for heat-engine plant heating by means of main steam

A main steam and thermal power plant technology, applied in the components of steam boilers, steam boilers, steam generation, etc., can solve the problems of waste of main steam, rising peak-to-valley difference, unsynchronized minimum load, etc. The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

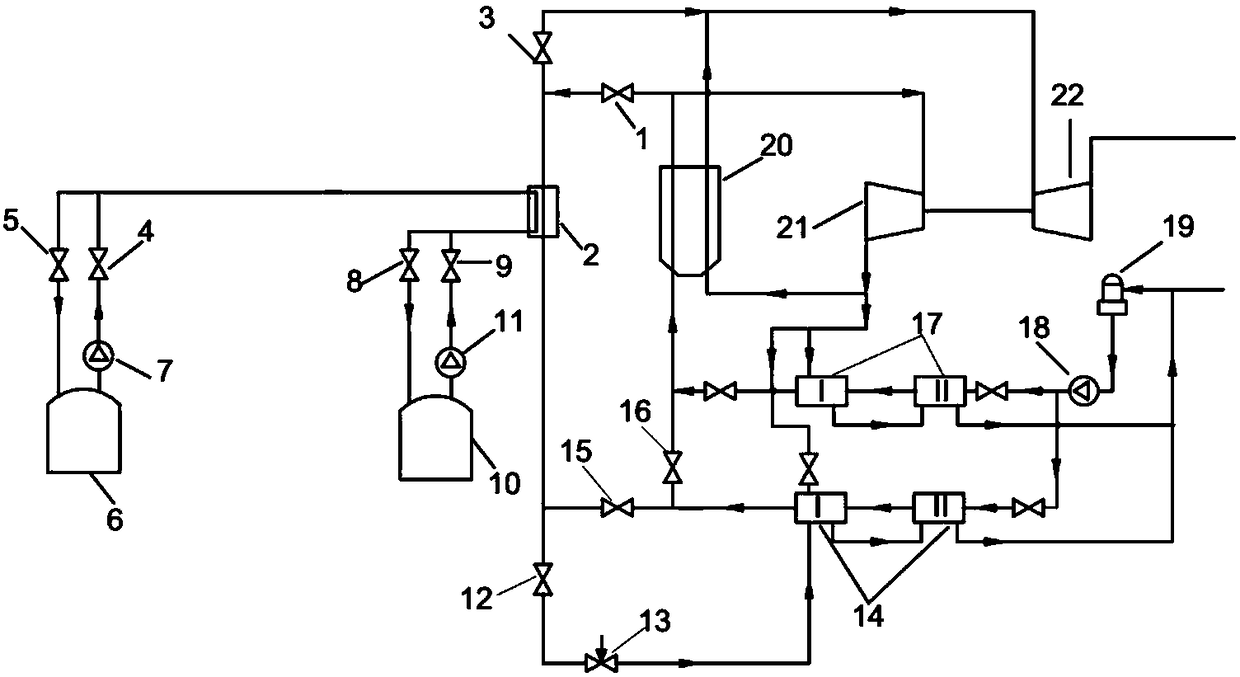

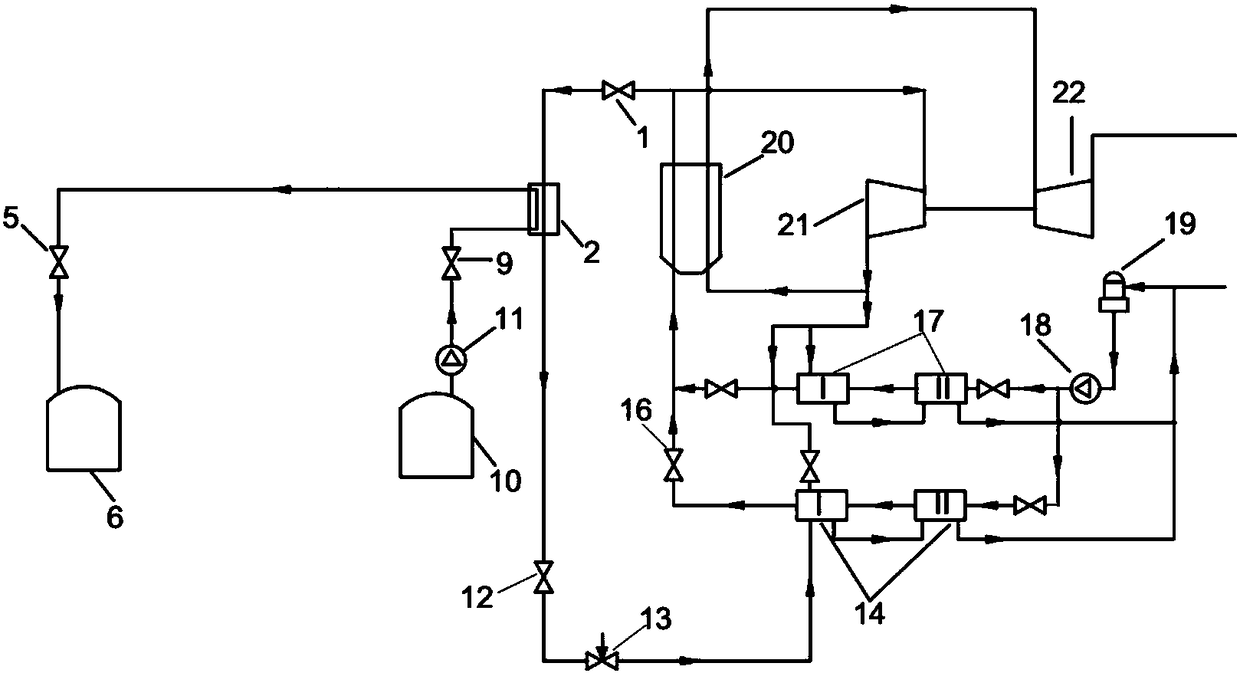

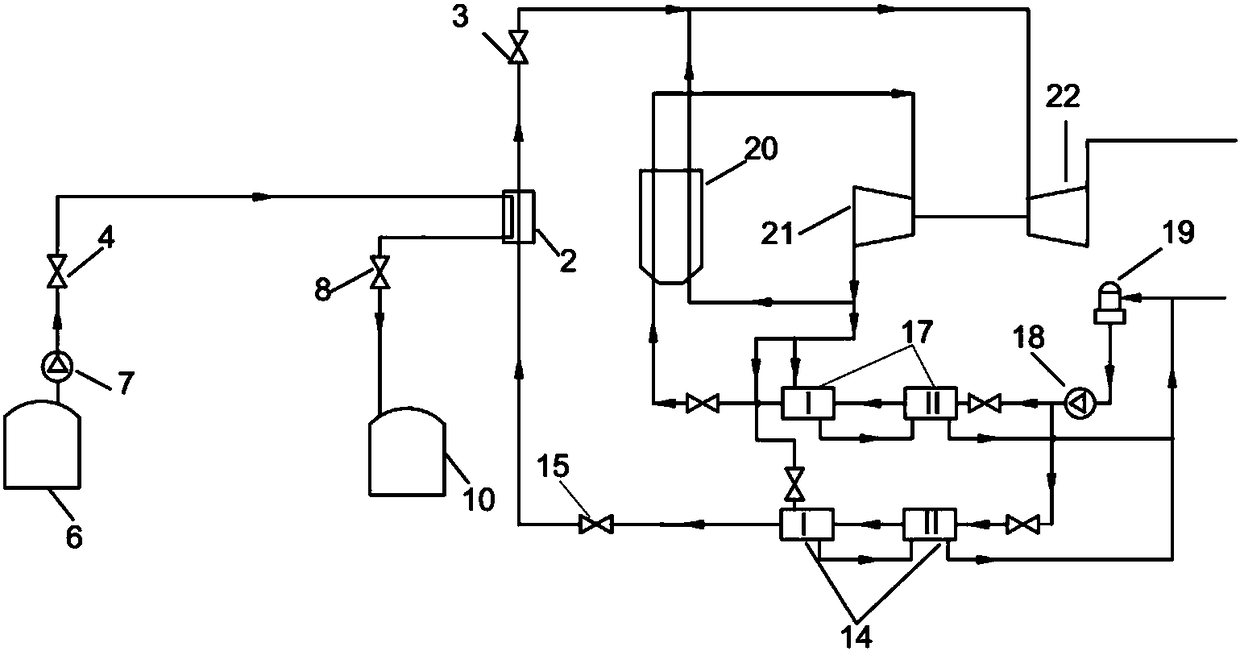

[0028] For specific component connections, see figure 1 , thermal storage, work see figure 2 , the schematic diagram of exothermic work is shown in image 3 .

[0029] Heat storage stage with low power load:

[0030] Such as figure 2 As shown, keep the boiler running at full load. When the power load is reduced, the unit is required to reduce the output power, open the main steam regulating valve 1, and close the reheat steam regulating valve 3, so that part of the main steam enters the steam turbine according to the original working mode of the power plant. After doing work, another part of the main steam flows into the high-pressure steam-molten salt heat exchanger 2, and the pipeline regulating valves 4, 8, 15 are closed, and the molten salt in the low-temperature cold salt tank 10 is pumped out by the low-temperature molten salt pump 11 and then sent into the high-pressure steam —The molten salt heat exchanger 2, the molten salt is heated and then flows back to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com