Large steel structure sunshine tree and sunshine tree manufacturing process

A technology of steel structure and sunshine, which is applied in the support structure of photovoltaic modules, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of low utilization rate of solar panel installation, improve the accuracy and quality of finished products, shorten the production period, reduce The effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

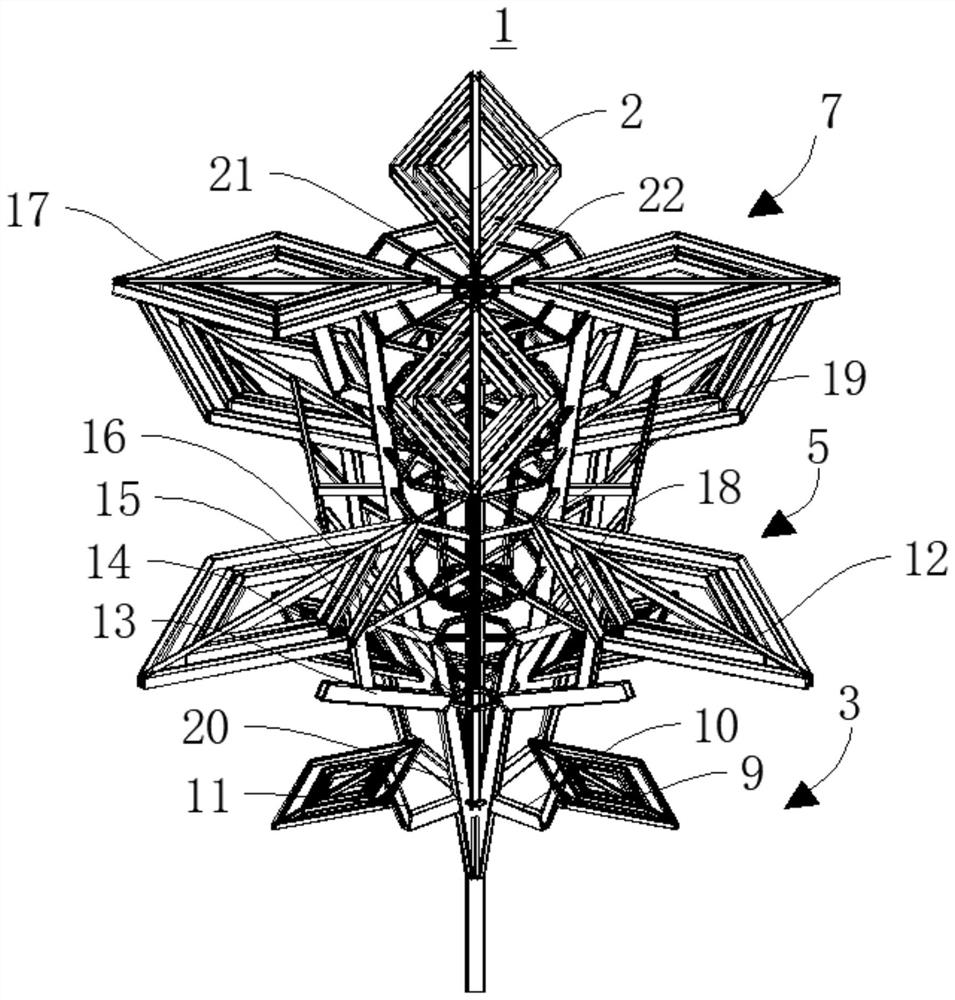

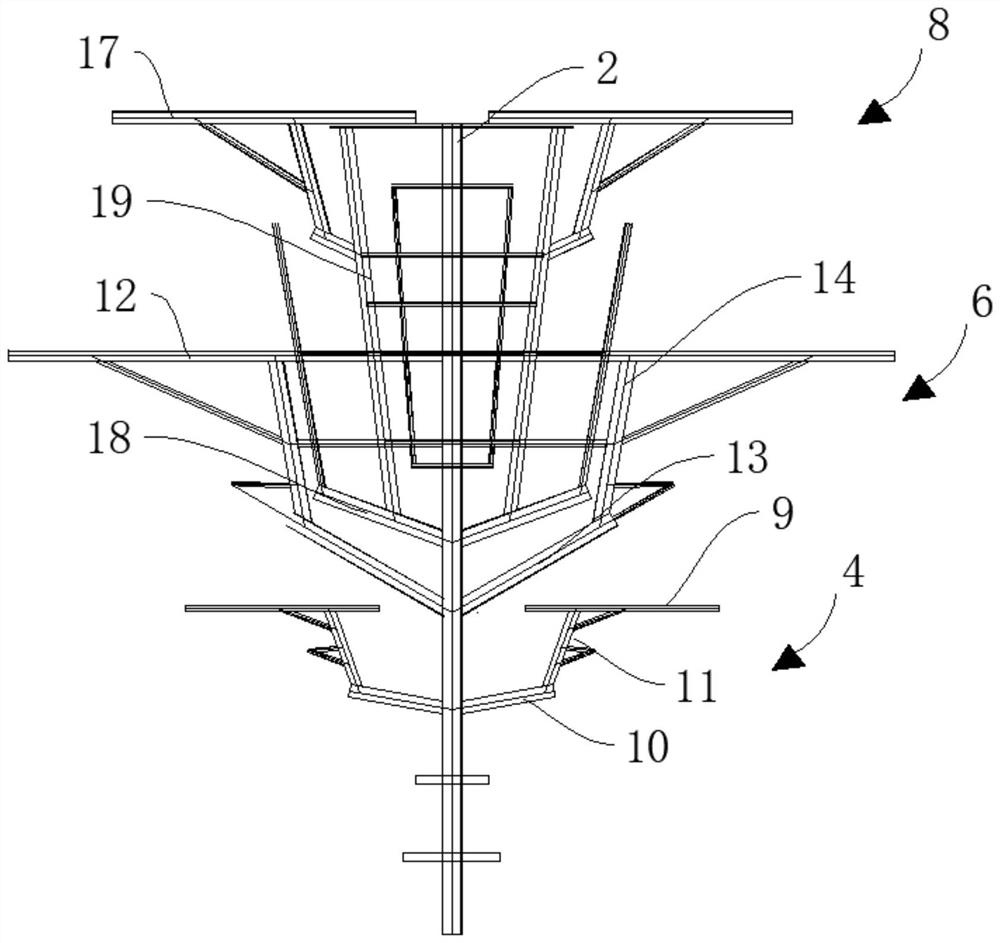

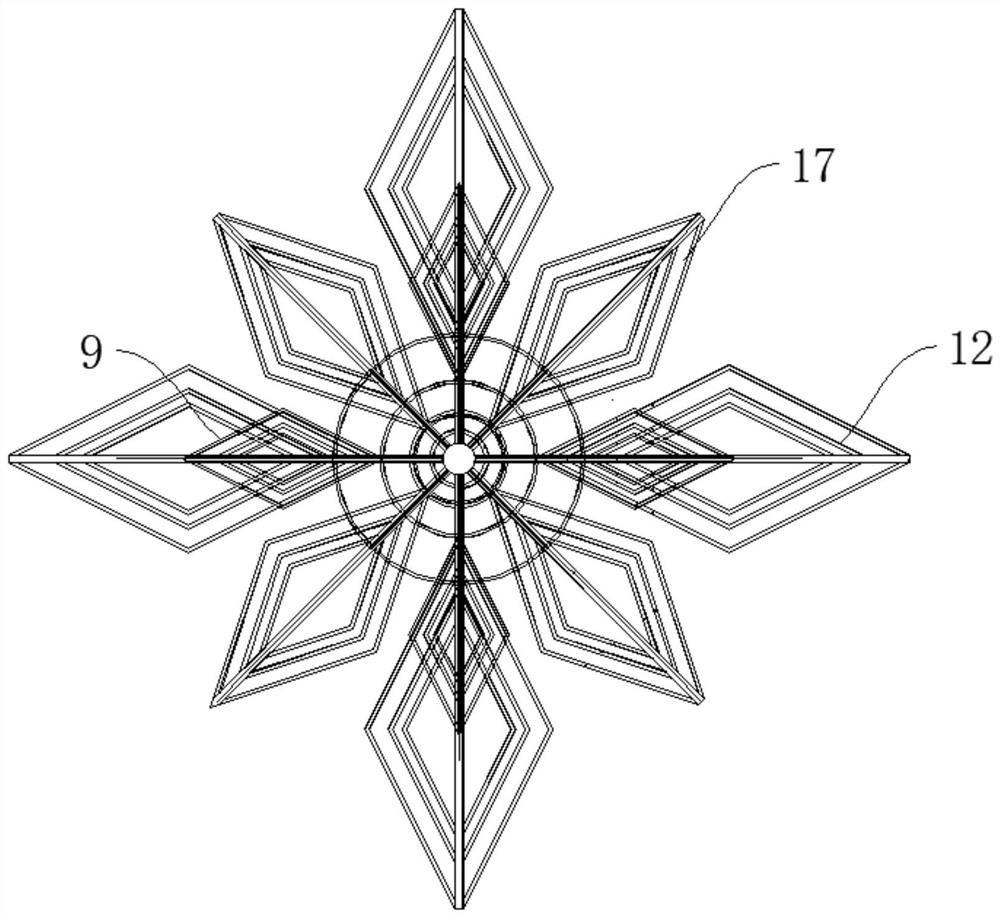

[0039] Please refer to figure 1 , with reference to figure 2 and image 3 , the application provides a large-scale steel structure sunshine tree 1, including a circular tube column 2, a first group of diamond-shaped components 3, a second group of rhombus components 5, and a third group of rhombus components 7; wherein, the circular tube column 2 is the sunshine tree The trunk of the tree, the first group of diamond-shaped components 3, the second group of rhombus-shaped components 5 and the third group of rhombus-shaped components 7 are respectively installed on the cylindrical column 2 from bottom to top at intervals as the leaves of the sunshine tree. The first group of rhombus-shaped components 3 is connected to the bottom of the round pipe column 2 through the first support structure 4, the second group of diamond-shaped members 5 is connected to the middle of the round pipe column 2 through the second support structure 6, and the third group of rhomboid members 7 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com