Method and apparatus for managing hydrogen sulfide tail gas

A hydrogen sulfide and tail gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of secondary pollution, high price, difficult implementation, etc., to prevent waste gas pollution, simple equipment, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

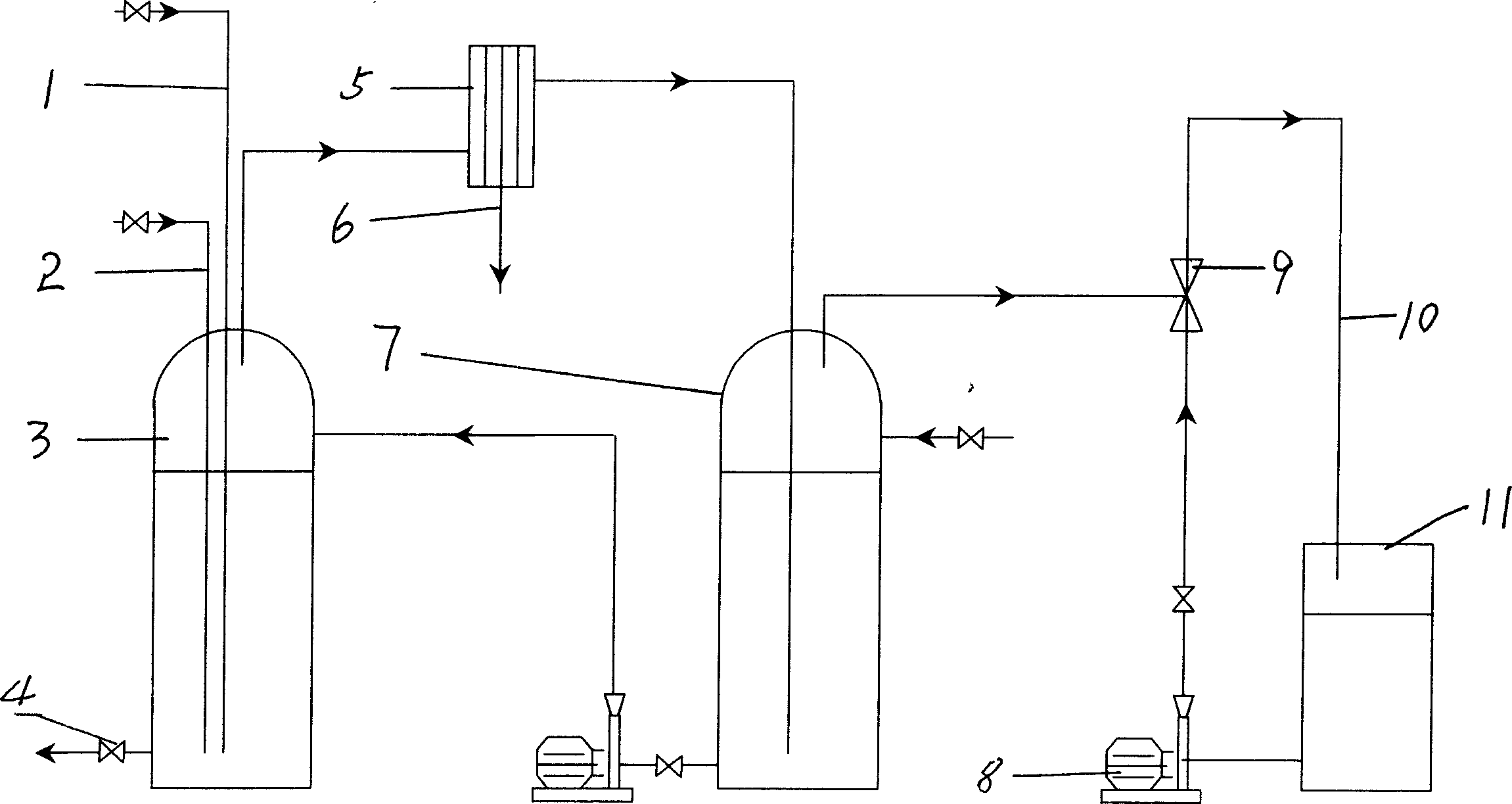

[0009] A method for treating hydrogen sulfide tail gas, (1) using a sodium hydroxide solution with a concentration of 30-42% as an absorbent, (2) introducing the hydrogen sulfide-containing tail gas into a container containing the absorbent (1) at a temperature of 50-80 Under the condition of ℃, carry out the reaction and absorption until the sodium hydroxide and hydrogen sulfide are converted into saturated sodium hydrosulfide solution, while the carbon disulfide gas continues to enter the condenser along the exhaust pipe, and condenses into liquid recovery under the condition of 17-30 ℃, ( 3) After the saturated sodium hydrosulfide solution is recovered, it is concentrated and crystallized into sodium hydrosulfide lamellar crystals for utilization.

[0010] A device for treating hydrogen sulfide tail gas, which includes two sets of equipment that can replace each other, each set of equipment is composed of a primary reaction vessel 3 and a secondary reaction vessel 7, and eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com