Steam heating ironing roller

A technology of ironing rollers and steam, which is applied in the direction of textiles and papermaking, fabric surface trimming, etc. It can solve the problems of affecting the economic benefits of production enterprises, the development limitation of oil heating ironing rollers, and the high energy consumption of electric heating ironing rollers, so as to achieve saving Use high power, improve the quality of ironing, and keep the temperature constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

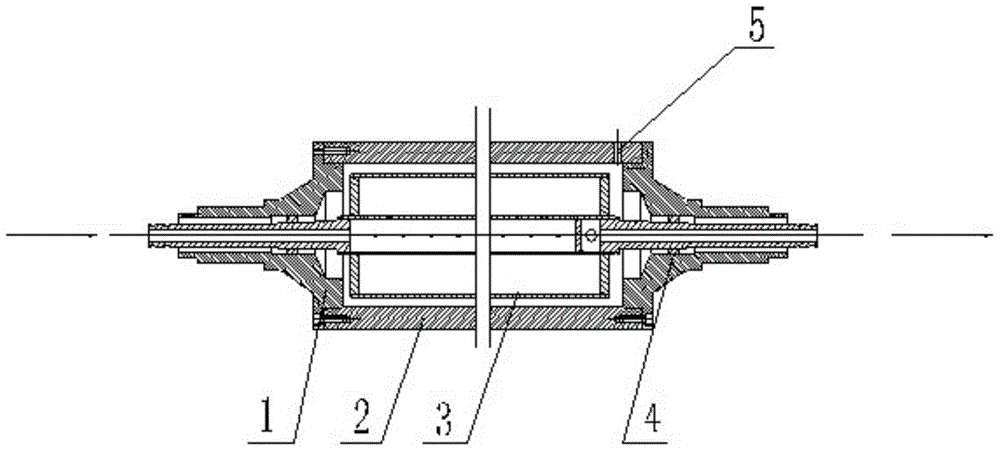

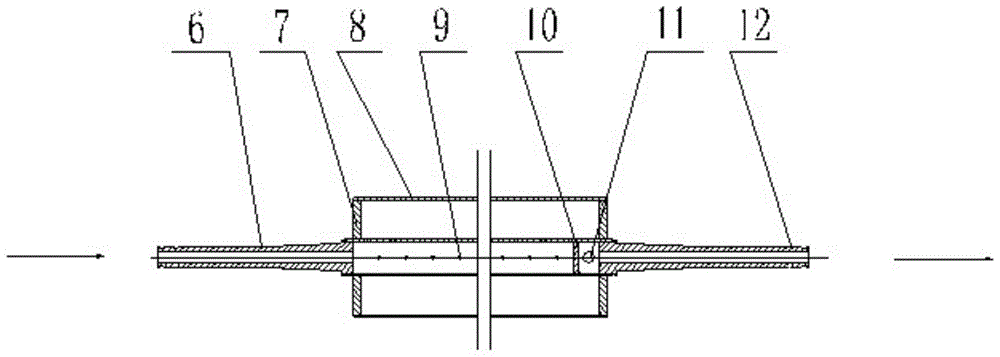

[0013] combine figure 1 and figure 2 :

[0014] A steam heating ironing roller of the present invention includes a shaft head 1, a ironing roller shell 2, a steam heating inner tank 3, and a bearing 4, wherein the steam heating inner tank 3 includes a roller shell 8, and the main shaft passing through the roller shell 8 6. The supporting flange 7 that supports the main shaft 6 at both ends of the roller shell 8 is sealed and fit between the supporting flange 7 and the main shaft 6 and the roller shell 8. The main shaft 6 is a hollow tubular structure, and the two ends of the main shaft 6 are respectively For the steam inlet and outlet, the main shaft 6 pipe wall located in the roller shell 8 is provided with an air injection hole 9, and the main shaft 6 located at the end of the roller shell 8 close to the steam outlet is provided with a blocking flange that cuts off the passage in the main shaft 6 10. There is a steam exhaust hole 11 on the pipe wall of the main shaft 6 be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com